High-strength wear-resistant ceramic powder

A ceramic powder, wear-resistant technology, applied in the direction of ceramic products, applications, household appliances, etc., can solve the problems of ceramic application restrictions, fragility, etc., to increase mechanical strength and structural toughness, improve strength and wear resistance , the effect of enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

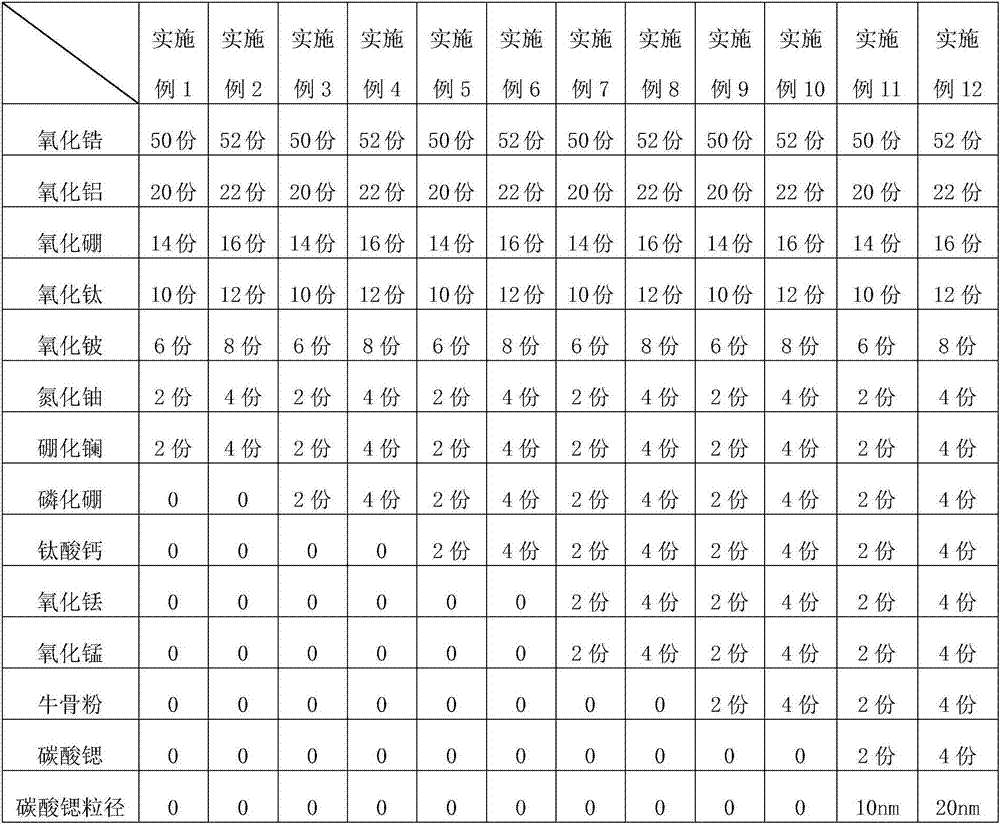

[0014] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

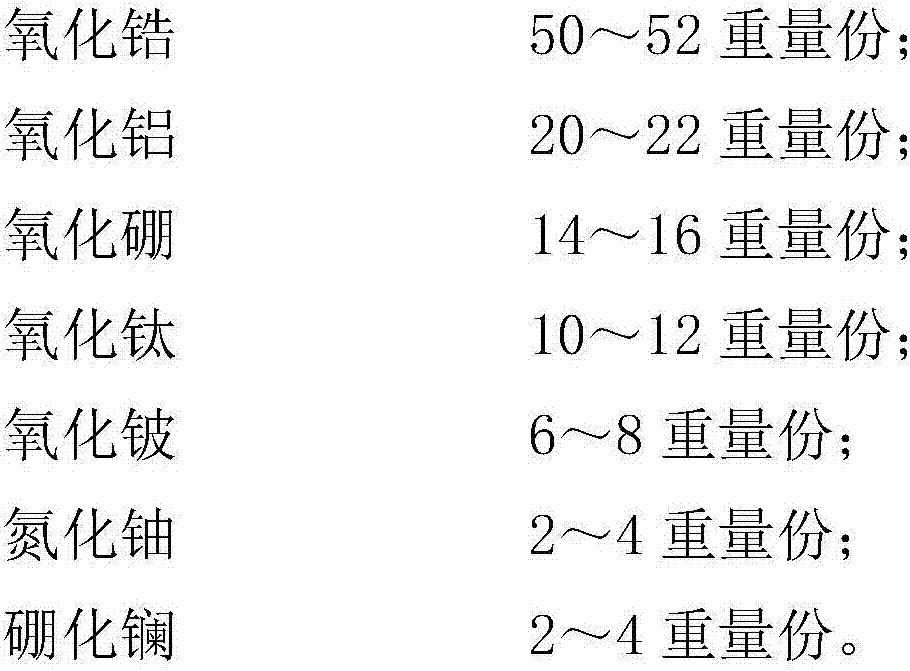

[0015] This case proposes an embodiment of high-strength wear-resistant ceramic powder, including the following materials by weight:

[0016]

[0017] As another embodiment of the present application, 2-4 parts by weight of boron phosphide are further included. Boron phosphide can synergistically improve the strength of ceramics, but it should be noted that the amount of boron phosphide added should be limited. If the amount of boron phosphide added is less than 2 parts by weight, the synergistic effect cannot be activated and the ceramic cannot be effectively improved. strength and toughness; if the addition of boron phosphide is greater than 4 parts by weight, boron phosphide will inhibit the effect of uranium nitride and lanthanum boride in ceramics, and during calcination, part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com