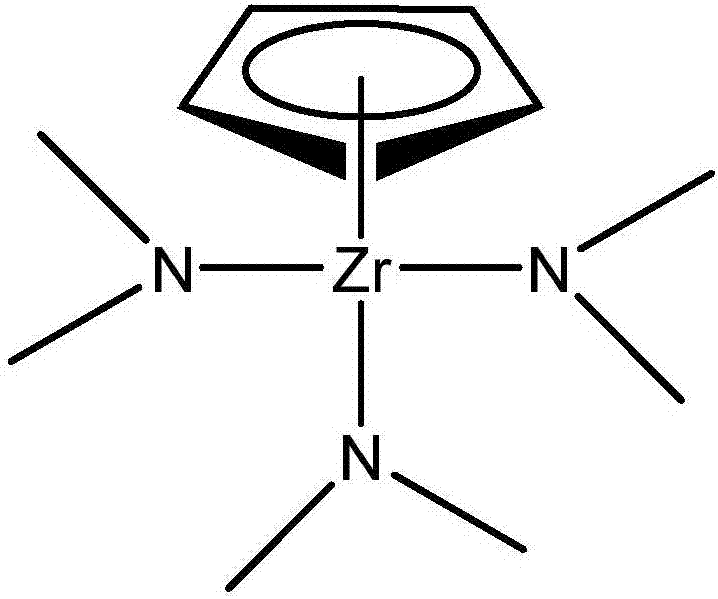

Preparation method of tris(dimethylamino) cyclopentadienyl zirconium

A technology of cyclopentadienyl zirconium and dicyclopentadiene, applied in chemical instruments and methods, organic chemistry, metallocene, etc., can solve the problems of silicon-based gate insulator leakage, impurity diffusion, shrinkage, etc. The effect of reducing environmental pollution, simplifying reaction treatment and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Under an inert atmosphere, add 500mL of n-hexane and 500mL of n-butyl lithium in n-hexane solution (2.5mol / L) to a 2L reaction flask, keep the temperature of the system at about -15°C, and feed in dimethylformamide while stirring. Amine (67 g), vented completely, warmed to room temperature and kept stirring for 4 hours.

[0044] (2) The temperature of the reaction liquid kettle in step (1) is lowered to below -10°C, under the protection of an inert gas, zirconium tetrachloride (71g) is added to the above reaction system, after the addition is completed, slowly return to room temperature, It was then heated to reflux for 12 hours.

[0045](3) Lower the temperature of the reaction solution in step (2) to below -10°C, pass the prepared cyclopentadiene monomer (23g) and 28mL toluene solution through a constant pressure dropping funnel under the protection of a mixed inert gas Add dropwise to the reaction solution in step (2), and keep the kettle temperature below -10°C...

Embodiment 2

[0048] (1) Under an inert atmosphere, add 500mL of n-hexane and dimethylamine (67g) to a 2L reaction flask, keep the temperature of the system at about -15°C, and slowly add 500mL of n-butyl lithium dropwise to the reaction flask while stirring The n-hexane solution (2.5mol / L) was added dropwise, and after rising to room temperature, stirring was maintained for 4 hours.

[0049] (2) Lower the temperature of the reaction liquid kettle in step (1) to about -15°C, under the protection of an inert gas, slowly add the n-hexane solution containing zirconium tetrachloride (71g) into the reaction flask dropwise, and the dropwise addition is completed After that, it was slowly returned to room temperature, and then heated to reflux for 12 hours.

[0050] (3) Lower the temperature of the reaction solution in step (2) to below -10°C, pass the prepared cyclopentadiene monomer (23g) and 28mL toluene solution through a constant pressure dropping funnel under the protection of a mixed inert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com