Preparation method of aging resistant modified natural rubber

A natural rubber, aging-resistant technology, applied in the field of preparation of aging-resistant modified natural rubber, can solve the problems of weak interaction, high production cost, small output, etc., to improve interface adhesion, improve mechanical properties, increase The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

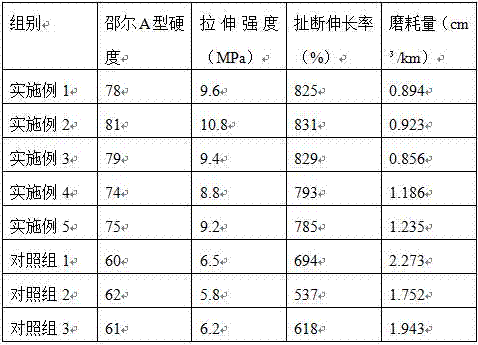

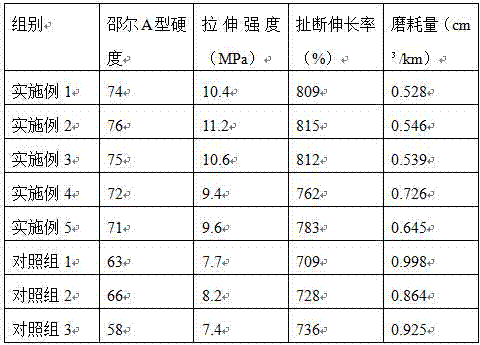

Examples

Embodiment 1

[0014] A preparation method of anti-aging modified natural rubber, comprising the following steps:

[0015] (1) Silica modification: Dry the silica at 220°C for 6 hours, then mix it with abietic acid type resin acid equivalent to 5% of its weight, and 15% chlorohydrin rubber at a temperature of 150°C. masticate for 23 minutes under the condition of ℃, extract continuously with tetrahydrofuran for 24 hours after discharge, and dry at 130 ℃ after the solvent evaporates to obtain modified white carbon black;

[0016] (2) Preparation of masterbatch: mix natural rubber, modified white carbon black, and multi-walled carbon nanotubes at a weight ratio of 10:1.5:0.6, mix the rubber materials in a double-roller mill, and mix to produce sheets. Put the obtained mixed rubber on an extruder to granulate.

[0017] Among them, the white carbon black is prepared and provided by our company. The specific surface area of the white carbon black is 170-180㎡ / g, which can effectively control th...

Embodiment 2

[0023] A preparation method of anti-aging modified natural rubber, comprising the following steps:

[0024] (1) Silica modification: Dry the silica at 200°C for 8 hours, then mix it with abietic acid type resin acid equivalent to 4% of its weight and 18% chlorohydrin rubber at a temperature of 140°C. masticate for 25 minutes under the condition of ℃, continuously extract with tetrahydrofuran for 24 hours after discharge, and dry at 120 ℃ after the solvent evaporates to obtain modified white carbon black;

[0025] (2) Preparation of masterbatch: mix natural rubber, modified white carbon black, and multi-walled carbon nanotubes at a weight ratio of 10:1.6:0.6, mix the rubber materials in a double-roller mill, and mix to produce sheets. Put the obtained mixed rubber on an extruder to granulate.

[0026] The rest of the content is the same as in Example 1.

Embodiment 3

[0028] A preparation method of anti-aging modified natural rubber, comprising the following steps:

[0029] (1) Silica modification: Dry the silica at 240°C for 4 hours, then mix it with abietic acid type resin acid equivalent to 7% of its weight, and 12% chlorohydrin rubber at a temperature of 160°C. masticate for 20 minutes under the condition of ℃, extract continuously with tetrahydrofuran for 24 hours after discharge, and dry at 150 ℃ after the solvent evaporates to obtain modified white carbon black;

[0030] (2) Preparation of masterbatch: mix natural rubber, modified white carbon black, and multi-walled carbon nanotubes at a weight ratio of 10:1.3:0.7, mix the rubber materials in a double-roll mill, and knead to produce sheets. Put the obtained mixed rubber on an extruder to granulate.

[0031] The rest of the content is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com