Porous nickel-based cathode material for hydrogen evolution reaction and preparation method thereof

A cathode material and electrolysis technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor corrosion resistance, high electrocatalytic activity, and low catalytic efficiency, and achieve excellent corrosion resistance and electrocatalytic activity. The effect of large and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

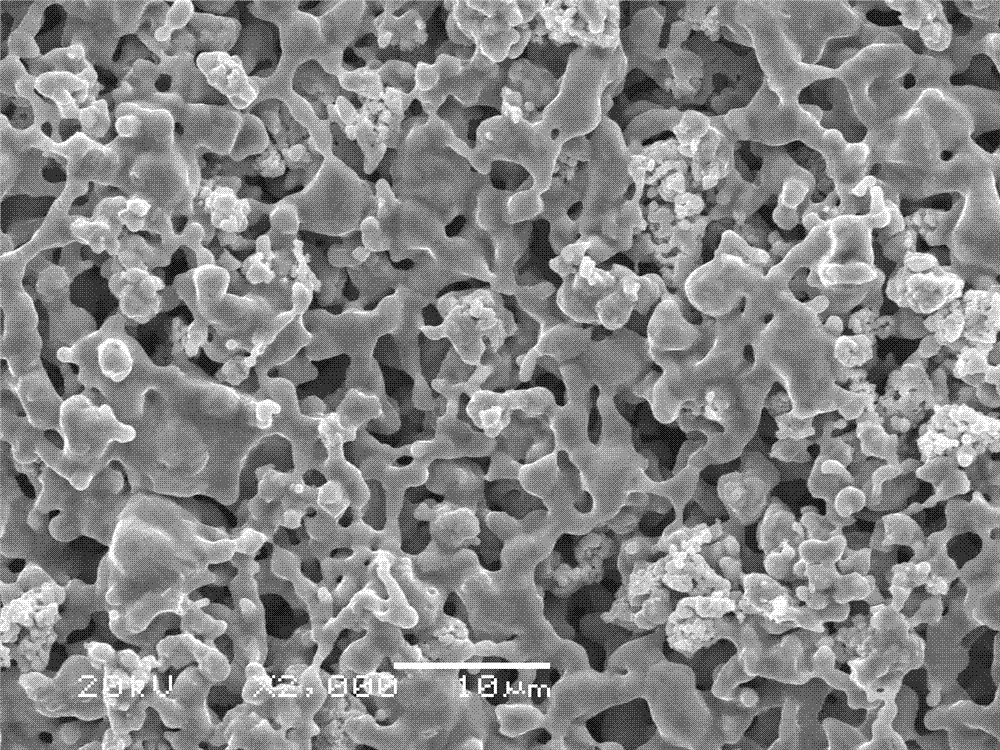

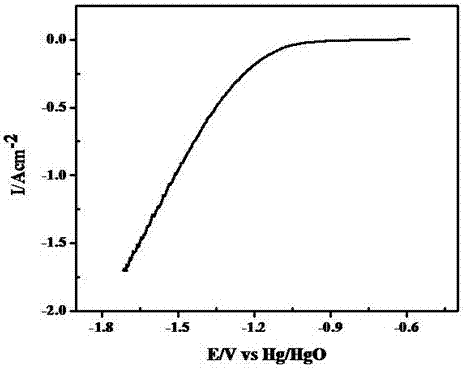

[0025] The 2μm Ni, Mo, Fe, W four element powders with a purity of more than 99.5% are prepared according to a certain mass percentage, of which Mo is 12%; Fe is 5%; W is 1%; the balance is iron powder. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 8 hours, add 1% stearic acid of the total powder mass, dry it in a common drying oven at 60°C for 5 hours, and then cold press it under a cold press at a pressure of 50 MPa Forming, the holding time is about 120s; the pressed sample is placed in a vacuum furnace, and the vacuum degree is 1×10 -2 In the case of Pa, keep a heating rate of 5°C / min, from room temperature to 280°C, and hold for 80 minutes; then raise the temperature to 480°C at a heating rate of 5°C / min, and hold for 60 minutes; then raise the temperature at a heating rate of 1°C / min to 590°C and keep at this temperature for 60min; then raise the temperature to 850°C at a heating rate of 5°C / min and keep at this temperature for 120mi...

Embodiment 2

[0035] The 5µm Ni, Mo, Fe, W four element powders with a purity of more than 99.5% are prepared according to a certain mass percentage, of which Mo is 25%; Fe is 15%; W is 10%; the balance is iron powder. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 14 hours, then add stearic acid with a total mass of 1.8% of the powder, dry it in an ordinary drying oven at 40°C for 10 hours, and then cold press it under a cold press at a pressure of 100 MPa Forming, the pressure holding time is about 90s; the pressed sample is placed in a vacuum furnace, and the vacuum degree is 1×10 -2 In the case of Pa, keep a heating rate of 6°C / min, from room temperature to 320°C, and hold for 70 minutes; then raise the temperature to 520°C at a heating rate of 10°C / min, and hold for 40 minutes; then raise the temperature at a heating rate of 5°C / min to 620°C and keep at this temperature for 60min; then raise the temperature to 950°C at a heating rate of 10°C / min and...

Embodiment 3

[0037] The 8µm Ni, Mo, Fe, W four element powders with a purity of more than 99.5% are prepared according to a certain mass percentage, of which Mo is 20%; Fe is 10%; W is 10%; the balance is iron powder. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 14 hours, then add 1.5% stearic acid of the total mass of the powder, dry it in an ordinary drying oven at 40°C for 7 hours, and then cold press it under a cold press at a pressure of 150 MPa Forming, the holding time is about 30s; the pressed sample is placed in a vacuum furnace, and the vacuum degree is 1.8×10 -3 In the case of Pa, keep the temperature rise rate of 3°C / min from room temperature to 360°C, and keep it for 60 minutes; then raise the temperature to 500°C at a rate of 7°C / min, and keep it for 50 minutes; then raise the temperature at a rate of 3°C / min to 600°C and keep at this temperature for 80min; then raise the temperature to 900°C at a heating rate of 8°C / min and keep at this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com