Fibrous membrane device capable of adsorbing-desorbing protein and based on 3D printing PLA material and preparation method thereof

A 3D printing and fiber membrane technology, applied in the field of protein separation and purification, can solve the problems of increasing process flow, increasing processing costs, limiting the expansion of separation and purification application fields, etc., to achieve the goal of ensuring separation efficiency, improving adsorption and improving recyclability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

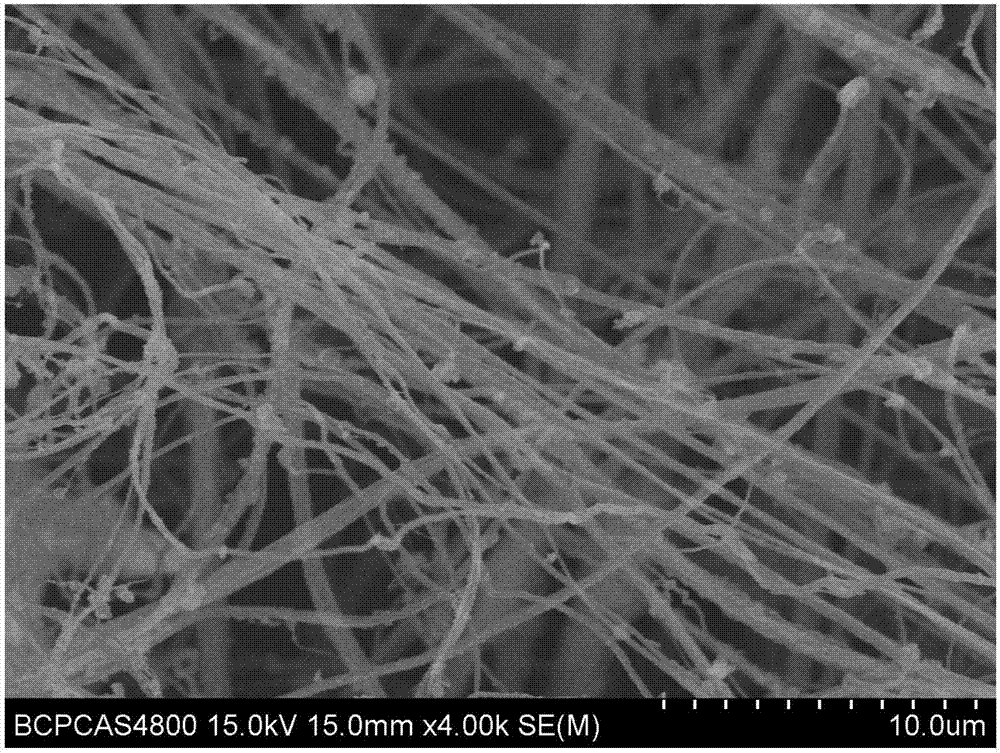

[0045] S11. Add 8g of bamboo pulp to the oxidation system of TEMPO (0.04g), NaBr (0.4g) and NaClO (10g), adjust the pH to 10.2 by NaOH, then react for 6.5h, and obtain the product by washing, filtering, and ultrasonic centrifugation Aqueous suspension of nanocellulose with a solid content of 0.2%.

[0046] 8.2 g of dimethyl sulfoxide was slowly added dropwise into the aqueous suspension, and then vacuumized and rotary evaporated at 80° C. for 4 hours to obtain a nanocellulose dimethyl sulfoxide suspension.

[0047] S12. Dissolve 1.64g of cellulose diacetate (the degree of substitution of acetyl group is 2.5, the molecular weight is 39000) in 8.03g of nanocellulose dimethyl sulfoxide suspension, until the cellulose diacetate is completely dissolved and the solution is transparent , and then 0.2g dimethyl sulfoxide and 6.1g trichloromethane were added dropwise into the solution, and then magnetically stirred at room temperature for 4 hours, then the stirring was stopped, left st...

Embodiment 2

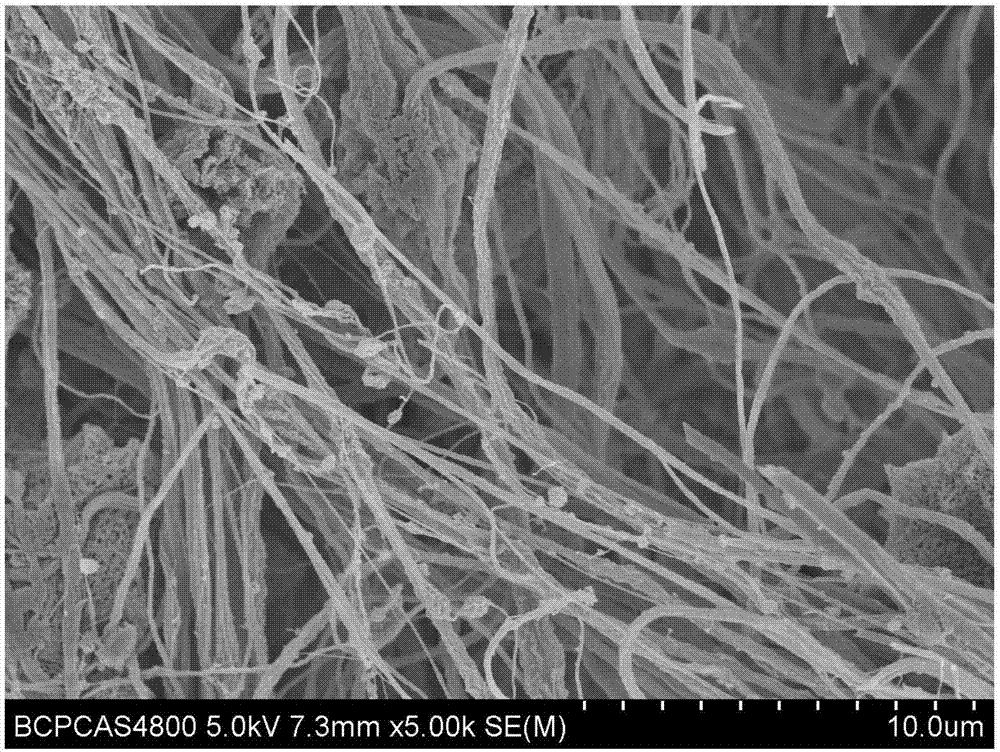

[0052] S21. Add 8g of bamboo pulp to the oxidation system of TEMPO (0.04g), NaBr (0.4g) and NaClO (10g), adjust the pH to 10.5 by NaOH, then react for 6.5h, and the product is obtained by washing, filtering, and ultrasonic centrifugation. Aqueous suspension of nanocellulose with a content of 0.2%.

[0053] 5.25 g of dimethyl sulfoxide was slowly added dropwise into the aqueous suspension, followed by rotary evaporation at 80° C. for 4 hours under vacuum to obtain a nanocellulose dimethyl sulfoxide suspension.

[0054] S22. Dissolve 2.1 g of cellulose diacetate (with an acetyl substitution degree of 2.3 and a molecular weight of 60,000) in the nanocellulose dimethyl sulfoxide suspension obtained in S21, and wait until the cellulose diacetate is completely dissolved and the solution becomes transparent , then add 4.65g dimethyl sulfoxide and 9.06g trichloromethane dropwise into the solution, then magnetically stir at room temperature for 8h, stop stirring, stand for defoaming, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com