Multifunctional pavement overlay structure beneficial to microwave heating

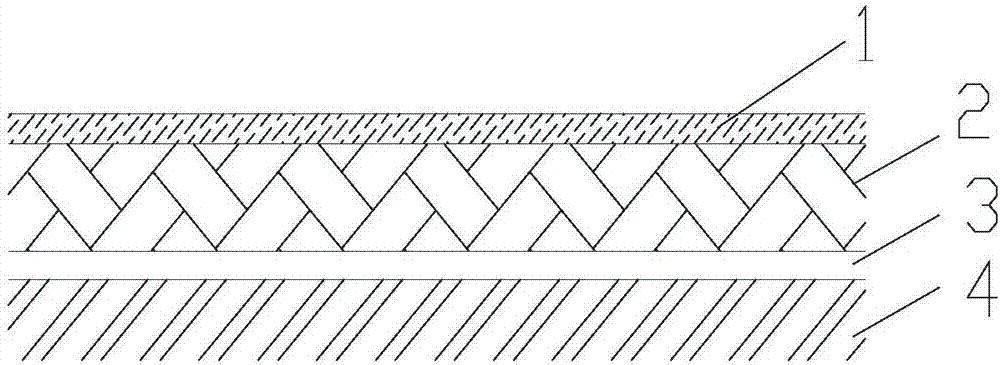

A microwave heating and multi-functional technology, which is applied to the condensable pavement, roads, roads and other directions of on-site paving, can solve the problems of limiting the development and popularization of microwave heating technology, low microwave heating efficiency, and large microwave heating depth of asphalt pavement, etc. Achieve the effect of improving utilization rate and microwave curing efficiency, improving microwave absorption and heating efficiency, and saving curing time and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

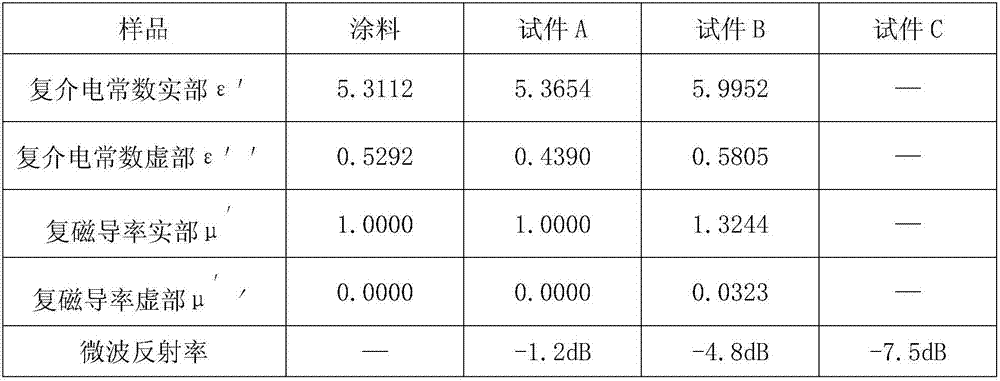

[0028] (1) Electromagnetic parameters and microwave reflectivity test of asphalt concrete

[0029] (1) prepare the used coating of microwave impedance matching layer in laboratory, the proportioning of described coating is counted as by weight ratio: waterborne epoxy resin: microwave absorber: auxiliary agent: curing agent=100:8:5:7, wherein Auxiliaries include dispersants, film-forming aids and anti-sedimentation agents, and the mass ratio is 1:1:0.8. The electromagnetic parameters of the coating at 2-6GHz microwave frequencies meet the real part of the dielectric constant measured by microwave vector network analysis. 31 The electromagnetic parameter test results of the coating at 2.45 GHz are shown in Table 1.

[0030] (2) Prepare AC-16 asphalt mixture in the laboratory according to JTGF40-2004 "Technical Specifications for Construction of Highway Asphalt Pavement". The asphalt used in the mixture is SBS modified asphalt, and the aggregate is 35% steel slag and 65 % basal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflectivity | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com