Improved coated separators for lithium batteries and related methods

A lithium battery, separator technology, applied in the manufacture and use of such separators, membranes, films with aqueous or water-based polymer coatings, the manufacture or use of such coated separators, the manufacture and use of such In the field of separators with ceramic coatings, it can solve the problems of difficult disposal, undesired emissions, and solvents that are not environmentally friendly, and achieve the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

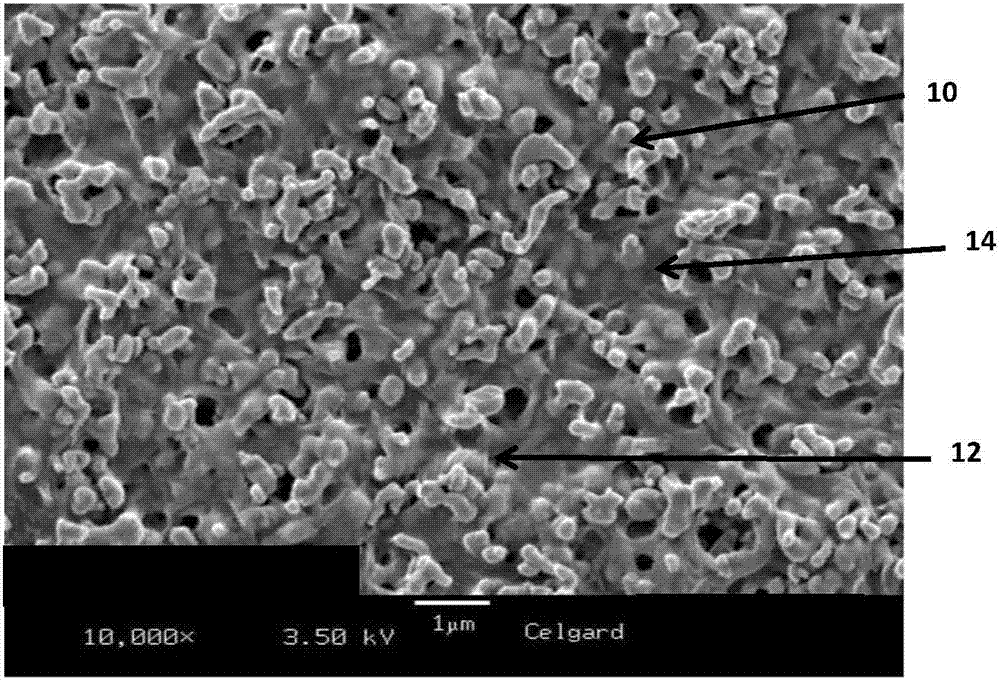

[0080] A water-based PVDF / ceramic coating slurry was prepared by uniformly dispersing 25 g of high-purity alumina particles with 18.7 g of Formulation #1; wherein the alumina particles had a D50 average particle size of 0.65 μm, 0.8 g / cm 3 bulk density (bulktapped density), 4.6m 2 BET surface area per gram; Formulation #1 is a 50:50 blend of Formulation #2 and Formulation #3, which are two aqueous solutions or suspensions of PVDF:HFP (from Pennsylvania, USA) Arkema Inc. of King of Prussia, belonging to Latex product line), the difference between the two lies in the content of HFP, which will be explained in more detail below. Mixing was made more intensive by first pre-wetting the alumina particles with the solution or suspension of Formulation #1. Dispersion was accomplished using a Silverson high shear L4M-5 mixer at 5000 rpm for 12 minutes at room temperature. Spread the slurry by hand with a spatula on the On the surface of 2400PP microporous membrane (by dry process...

Embodiment 2

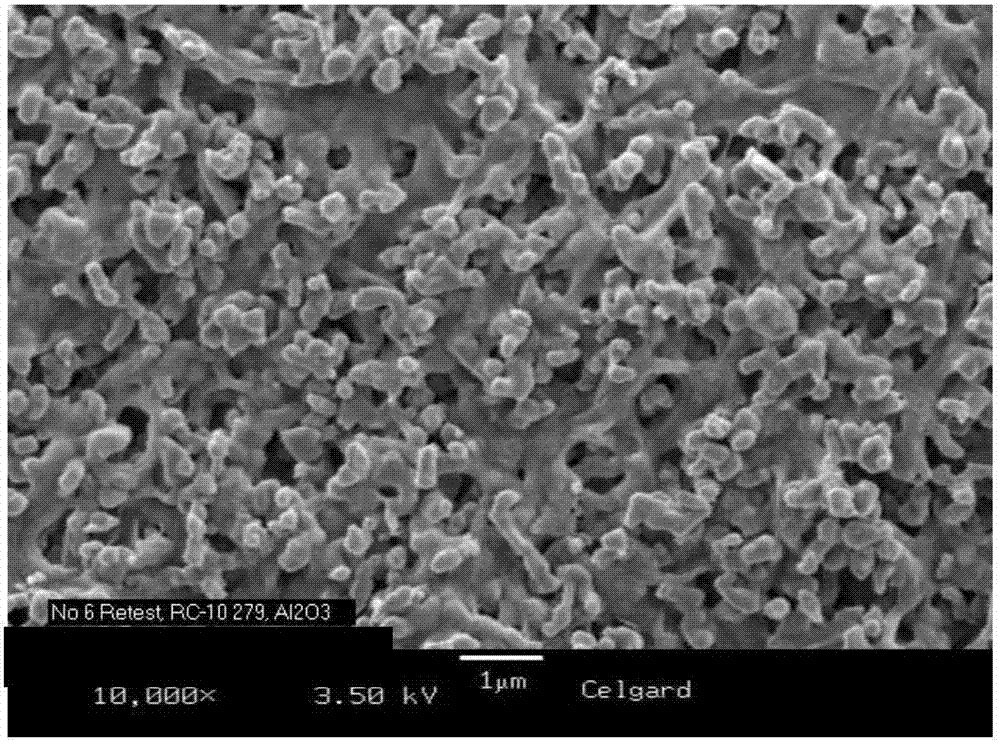

[0084] An aqueous based PVDF / ceramic coating slurry was prepared by uniformly dispersing 39 g of high purity alumina particles with 16.8 g of the PVDF blend of Formulation #1 described in Example 1; wherein the alumina particles had a D50 average particle size of 0.65 μm Diameter, 0.8g / cm 3 bulk density, 4.6m 2 / g of BET surface area. Mixing was made more intensive by first pre-wetting the alumina particles with the solution or suspension of Formulation #1. Dispersion was accomplished by first mixing with a Silverson high shear L4M-5 mixer at 5000 rpm at room temperature for 12 minutes, followed by mixing with a ball mill mixer (MTI Shimmy ball mill mixer) for 20 minutes. The ceramic / PVDF slurry was manually spread on the On the surface of the 2400PP microporous membrane (example 1 above describes the characteristics of the membrane), moisture was removed by drying in an oven at 79°C. figure 2A SEM of the surface of this coated separator membrane is shown at 10,000X magn...

Embodiment 3

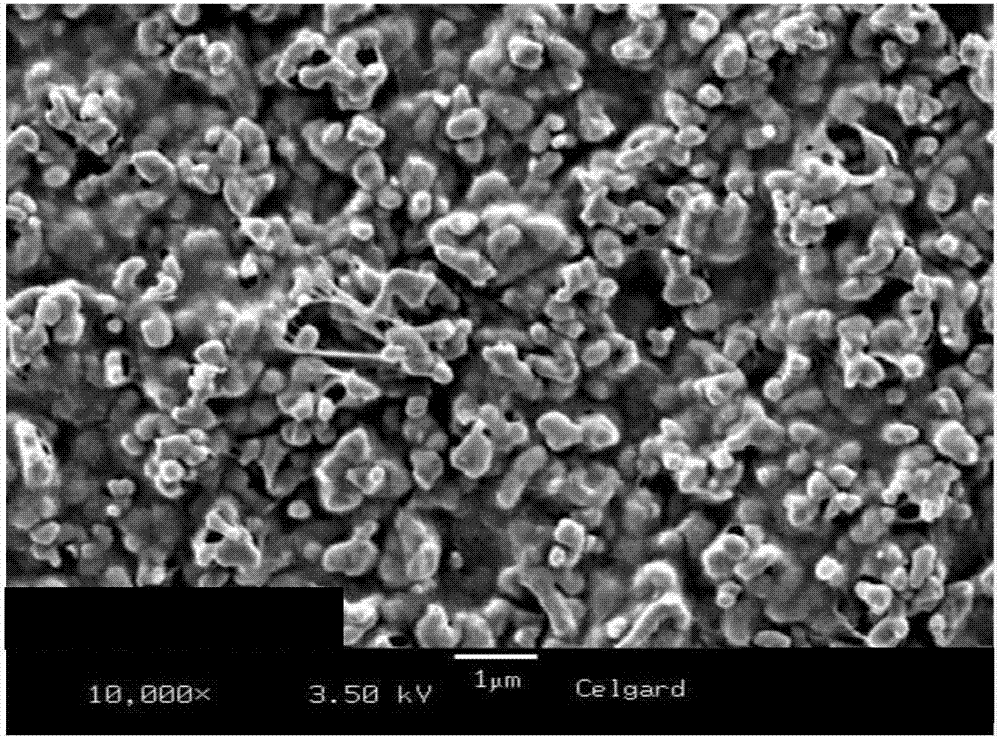

[0086] A water-based PVDF / ceramic coating slurry was prepared by mixing and uniformly dispersing 66 g of high-purity alumina particles with 23.5 g of Formulation #2; wherein the alumina particles had a D50 average particle size of 0.65 μm, 0.8 g / cm 3 bulk density, 4.6m 2 / g of BET surface area, recipe #2 is from Arkema Latex preparations are generally described as an aqueous suspension of water and PVDF:HFP, wherein water constitutes 55-65%, PVDF:HFP has a melting point in the range of about 114°C-120°C. Mixing was made more intensive by first pre-wetting the alumina particles with the solution or suspension of formulation #2. Dispersion was accomplished by first mixing with a Silverson high shear L4M-5 mixer at 3000 rpm at room temperature for 5 minutes, followed by mixing with a ball mill mixer (MTIShimmy ball mill mixer) for 20 minutes. Spread the slurry by hand with a spatula on the On the surface of EK0940 polyethylene microporous membrane (film prepared by wet proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com