Seven-degree-of-freedom water jet cutter

A water jet and cutter technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of unfavorable finishing, high price of EDM equipment, low precision, etc., and achieve low tool loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

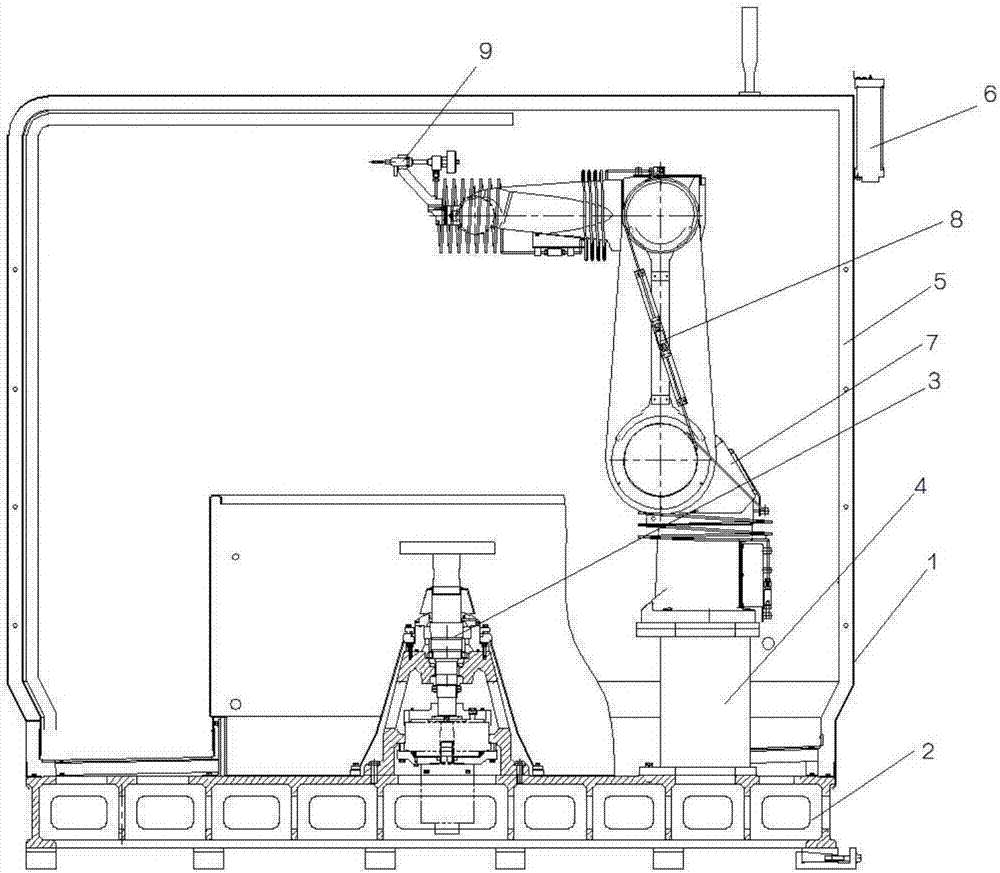

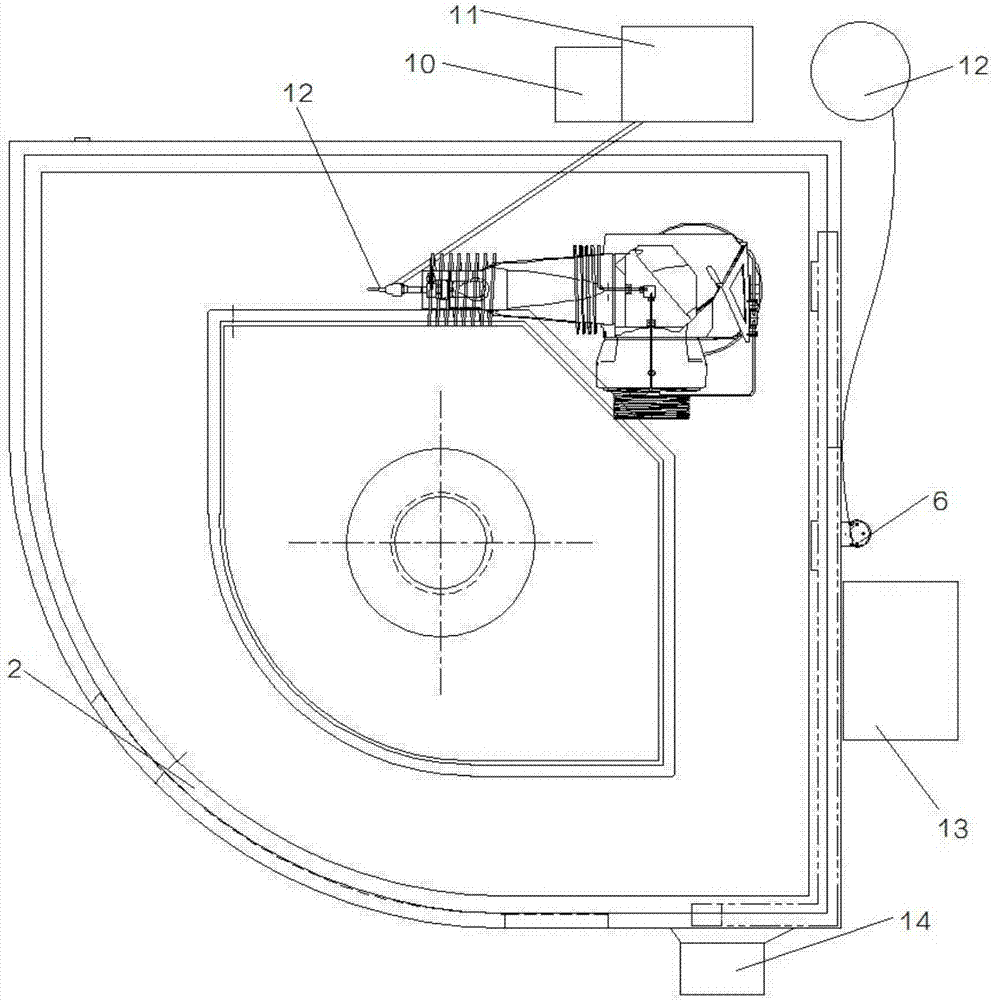

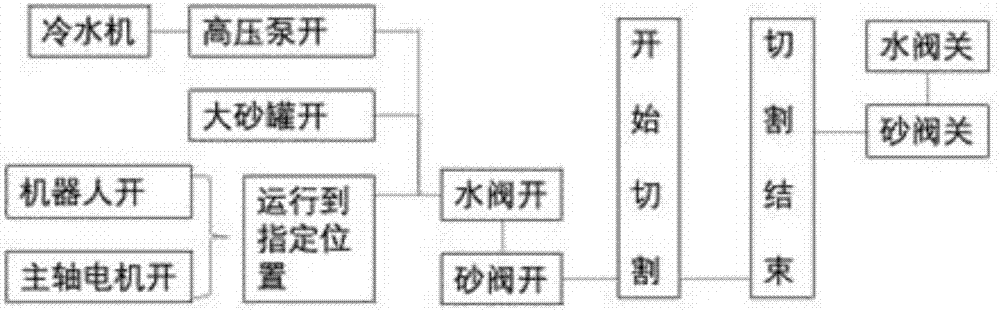

[0033] Such as figure 1 As shown, a seven-degree-of-freedom water jet cutter includes a housing 1; the bottom of the housing 1 is provided with a base 2, and the base 2 is provided with a rotating table 3 and a bracket 4 for supporting a robot 7, rotating Workbench 3, protection device 5 and other mechanisms are integral casting structures. The base 2 is integrally cast with HT300, which is the base of the entire equipment; the inner wall of the housing 1 is provided with a protection device 5, which frames the working of the device The area is used to provide protective devices for the processing area, which not only prevents the entry of foreign objects, but also prevents the splashing of water vapor and sand during processing. A small sand tank 6 is provided at the outer end of the shell 1; a robot 7 is provided on the support 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com