Three-dimensional crimped sheath-core composite fiber and nanofiber compound sound insulation material and preparation method thereof

A composite fiber and three-dimensional crimping technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of unfavorable low-frequency noise absorption, large holes, and restrictions on the promotion and use of sound insulation products, and achieve excellent Sound-absorbing and sound-insulating performance, improved sound-absorbing and sound-insulating performance, small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

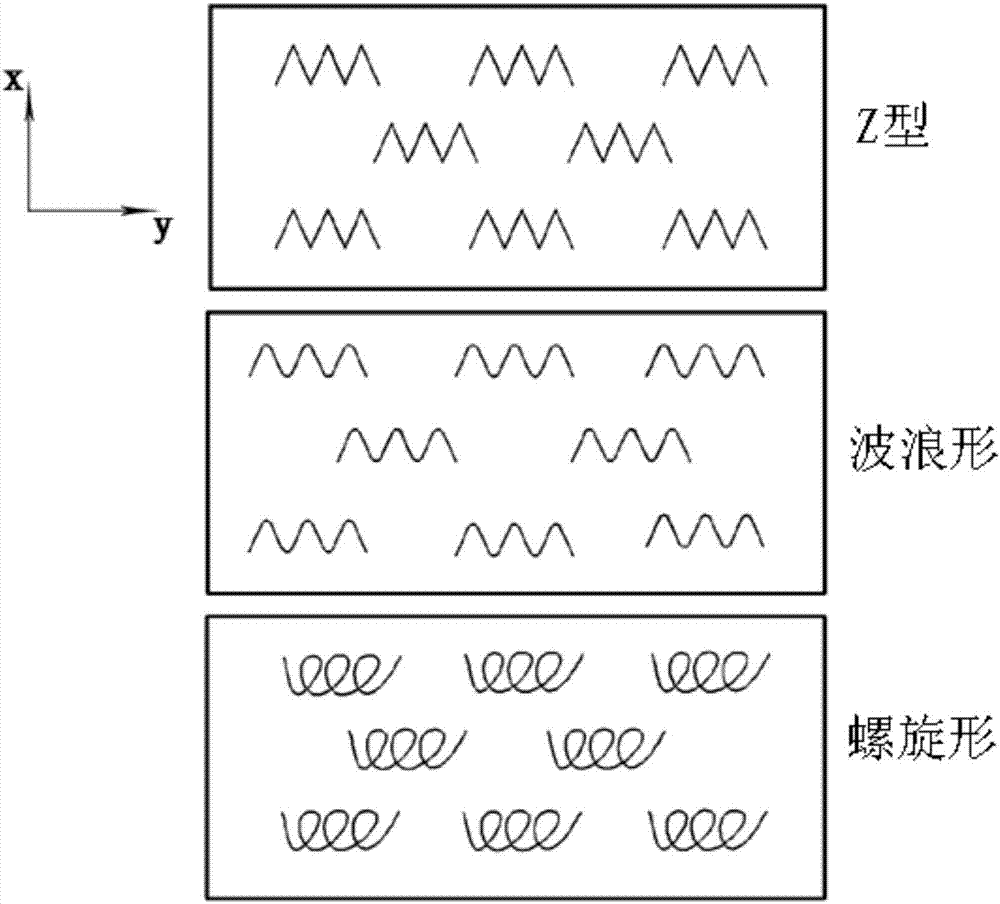

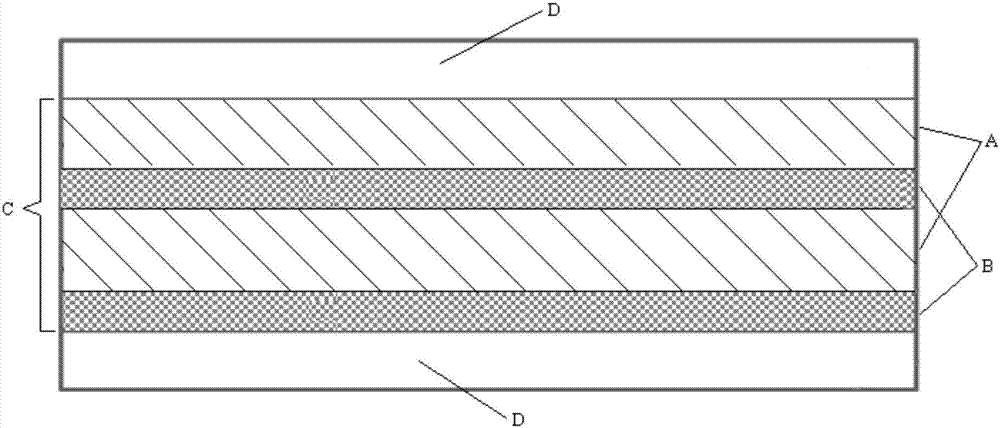

[0037] In this embodiment, the sheath material of the sheath-core composite fiber is polylactic acid (PLA), the core material is polycaprolactone (PCL), and has an eccentric structure. The three-dimensional crimped sheath-core composite fiber forms a Z-shaped permanent crimp under the action of heat by utilizing the different shrinkage rates of different polymers. The fiber diameter is 2 μm, and the fiber cross-section is circular. The three-dimensional crimped skin-core composite fiber layer A is made by twin-screw process, and is formed into a nonwoven fabric by spunbonding, with an area density of 30g / m 2 , the thickness is 3mm. The Z-shaped crimped fibers are vertically oriented in the fiber layer.

[0038] The nanofiber layer B is formed by needle electrospinning, and polylactic acid is used as the raw material for forming nanofibers. Polylactic acid (PLA, M w =3×10 5 g / mol) after vacuum-drying (60°C, 12h), using chloroform as a solvent to prepare a 20% solution, magnet...

Embodiment 2

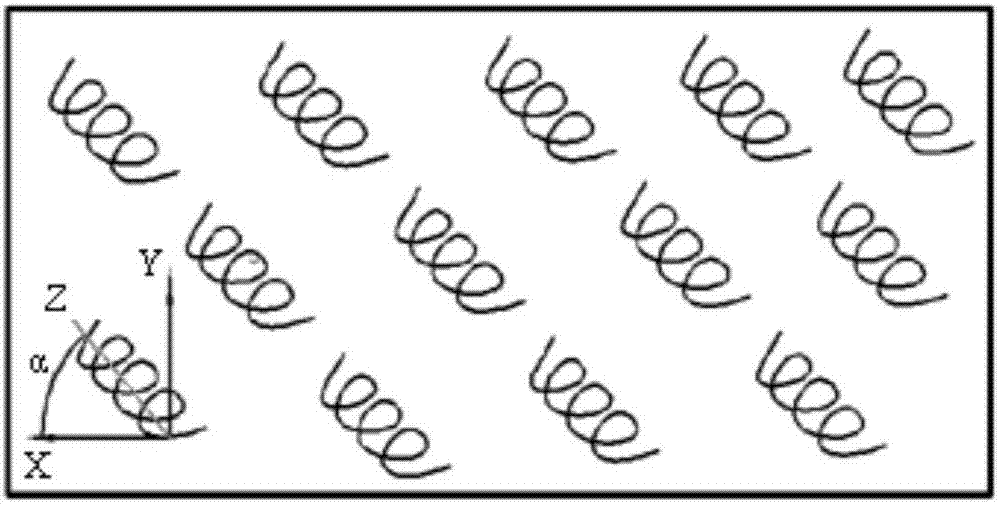

[0042] In this embodiment, the skin material of the three-dimensional crimped sheath-core composite fiber is polylactic acid (PLA), and the core material is polyester (PET). The three-dimensional crimped sheath-core composite fiber has a helical crimp structure, the fiber diameter is 4 μm, and the fiber cross section is circular. The filaments are made by twin-screw technology, and permanent three-dimensional crimps are obtained through mechanical crimping and heat setting, and then cut into short fibers. After carding, webbing, and hot air bonding, the fiber aggregate structure is obtained. The surface density is 30g / m 2 , the thickness is 3mm. The included angle between the three-dimensional crimped fibers and the fiber layer in the fiber layer is 45° and aligned.

[0043] The nanofiber layer is formed by electrospinning with free-surface wire electrodes without needles, and polylactic acid is used as the raw material for forming nanofibers. Polylactic acid (PLA, M w =3...

Embodiment 3

[0047] In this embodiment, the skin layer material of the three-dimensional crimped sheath-core composite fiber is nylon 6 (PA6) and nylon 6 / 66 copolymerized nylon, and the skin layer is a juxtaposed structure composed of two polymers; the core layer material is ionic liquid. The three-dimensional crimped sheath-core composite fiber has a helical crimp structure, the fiber diameter is 50 μm, and the fiber cross section is circular. The three-dimensional crimped skin-core composite fiber is made into filaments by single screw + plunger pump technology, and then warp and weft weaving to obtain a cloth structure, with an area density of 40g / m 2 , the thickness is 3mm. The angles between the three-dimensional crimped fibers and the fiber layer in the fiber layer are arranged at 60° and 0°.

[0048] The nanofiber layer is formed by centrifugal electrospinning, and polyhydroxyalkanoate is used as a raw material for forming nanofibers. Polyhydroxyalkanoate (intrinsic viscosity 0.7-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com