Soluble molecularly-imprinted polymer and application thereof

A molecularly imprinted and polymer technology, applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problem of difficult to obtain sensitive membranes, insoluble, and not yet soluble molecularly imprinted polymers. Soluble molecularly imprinted polymer membrane ions Detection and reporting problems, to achieve the effect of enhancing molecular recognition ability and improving response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

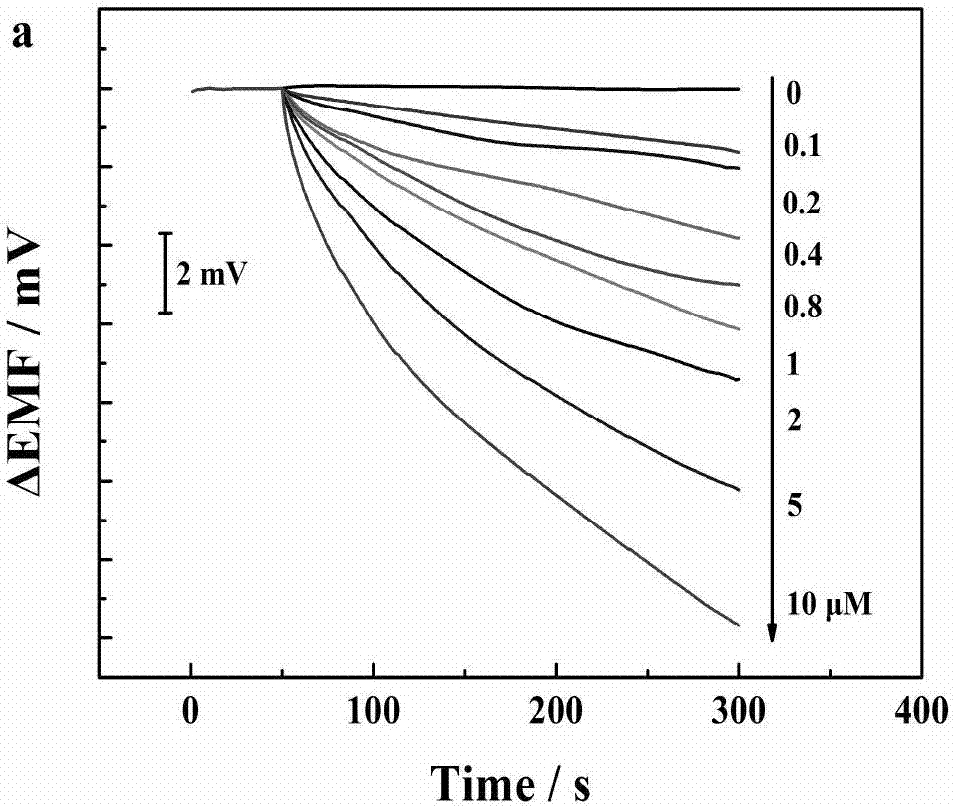

[0035] Take the detection of phenolic pollutant molecules in river water by the present invention: bisphenol AF as an example. Its determination steps are as follows:

[0036] 1) Preparation of molecularly imprinted polymers:

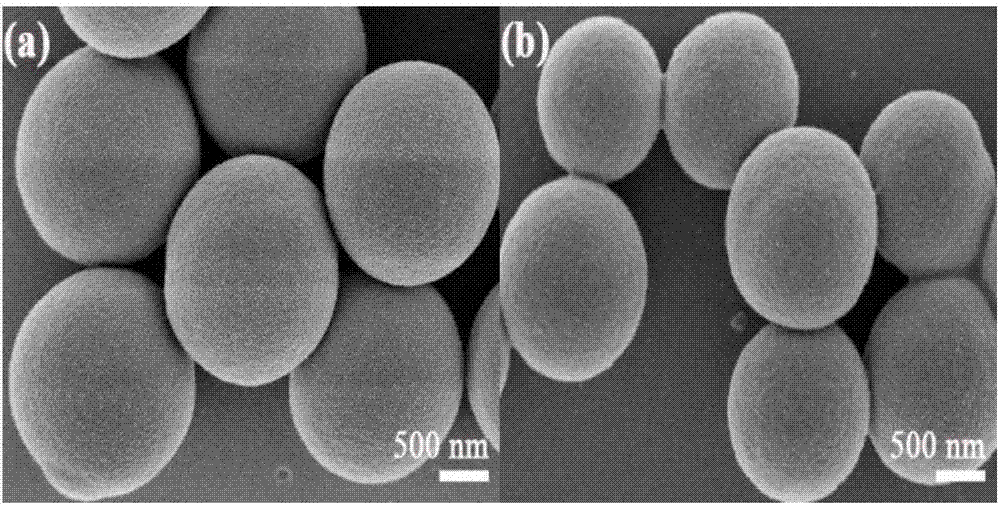

[0037] a. Preparation of insoluble molecularly imprinted polymer: Take 0.5 mmol of bisphenol AF and 2 mmol of pre-vacuum distilled methacrylic acid monomer into a 50 mL round bottom flask, and then add 10 mmol of crosslinking agent diethylene to the above mixture Benzene, 25 mg of initiator azobisisobutyronitrile and 12.5 mL of acetonitrile, ultrasonically oscillate for 5 min, and after mixing uniformly, finally pass nitrogen gas for 15 min to remove the oxygen present in the reaction solution, and seal it. The above reaction vessel was moved to an oil bath and heated at 80°C for 24 hours to obtain white solid particles.

[0038] The above-mentioned white solid particles were alternately washed three times with methanol / acetic acid (8:2, v / v) mixed so...

Embodiment 2

[0046] The difference from Example 1 is that the detection of bisphenol AF, a phenolic pollutant molecule in river water, is taken as an example. Its determination steps are as follows:

[0047] Preparation of Molecularly Imprinted Polymers:

[0048] a. Preparation of insoluble molecularly imprinted polymer: Take 0.5mmol of bisphenol AF and 2mmol of methacrylic acid monomer pre-vacuum distilled into a 50mL round bottom flask, and then add 10mmol of cross-linking agent di to the above mixture Vinylbenzene, 25 mg of initiator azobisisobutyronitrile and 12.5 mL of acetonitrile were vibrated ultrasonically for 5 minutes. After mixing evenly, nitrogen gas was flowed for 15 minutes to remove the oxygen existing in the reaction solution, and sealed. The above reaction vessel was moved to an oil bath and heated at 80°C for 24 hours to obtain white solid particles.

[0049] The above-mentioned white solid particles were alternately washed three times with methanol / acetic acid (8:2, v...

Embodiment 3

[0052] The difference from Example 1 is that the detection of bisphenol AF, a phenolic pollutant molecule in river water, is taken as an example. Its determination steps are as follows:

[0053] Preparation of Molecularly Imprinted Polymers:

[0054] a. Preparation of insoluble molecularly imprinted polymer: Take 0.5mmol of bisphenol AF and 2mmol of methacrylic acid monomer pre-vacuum distilled into a 50mL round bottom flask, and then add 10mmol of cross-linking agent di to the above mixture Vinylbenzene, 25 mg of initiator azobisisobutyronitrile and 12.5 mL of acetonitrile were vibrated ultrasonically for 5 minutes. After mixing evenly, nitrogen gas was flowed for 15 minutes to remove the oxygen existing in the reaction solution, and sealed. The above reaction vessel was moved to an oil bath and heated at 80°C for 24 hours to obtain white solid particles.

[0055] The above-mentioned white solid particles were alternately washed three times with methanol / acetic acid (8:2, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com