Metal corrosion-resistant composite material coating and preparation method thereof

A composite material, metal anti-corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve the problem of difficult to adhere to metal substrates, and achieve the effect of preventing metal corrosion, good toughness and strong viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

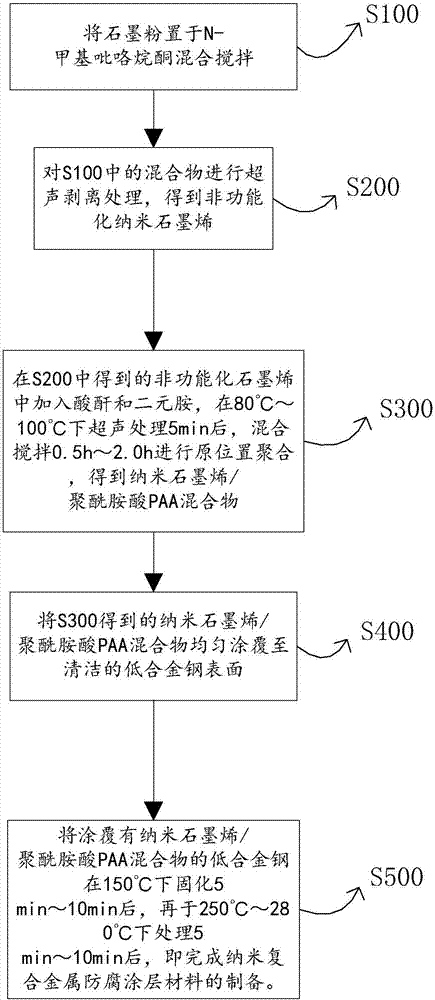

[0049] Embodiment 1 adopts following preparation method:

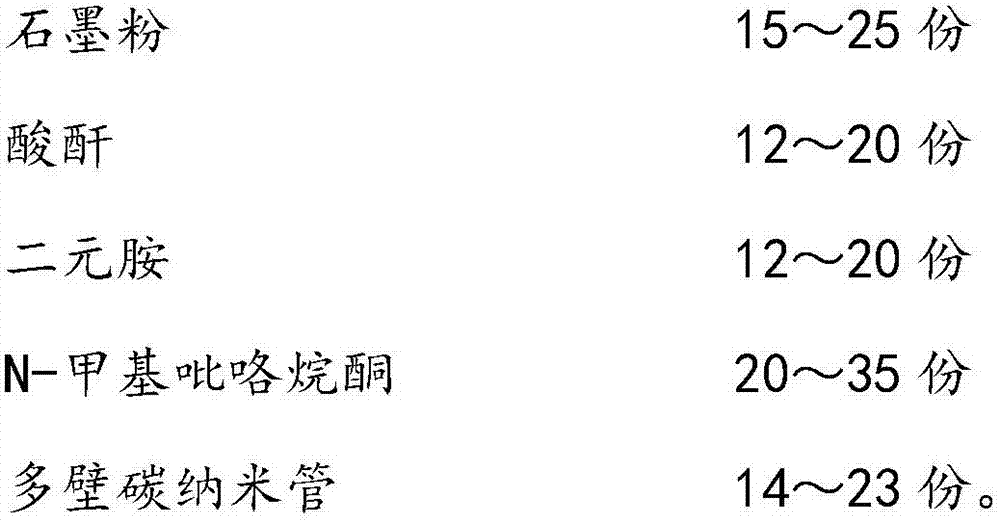

[0050] S100, mixing and stirring 15 parts of graphite powder in 22 parts of N-methylpyrrolidone;

[0051] S200, performing ultrasonic exfoliation on the mixture in S100 to obtain non-functionalized nano-graphene;

[0052] S300, adding 16 parts of acetic anhydride and 16 parts of m-phenylenediamine to the non-functionalized graphene obtained in S200, after ultrasonic treatment at 80°C to 100°C for 5 minutes, mixing and stirring for 0.5h to 2.0h to carry out in-situ polymerization, After in-situ polymerization of acid anhydride and diamine to generate polyamic acid, a nano-graphene / polyamic acid mixture is obtained;

[0053] S400, the nanographene / polyamic acid mixture that S300 is obtained is evenly coated on the alloy steel surface of cleaning;

[0054] S500. After curing the alloy steel coated with nano-graphene / polyamic acid mixture at 150°C for 5 minutes to 10 minutes, and then curing at 250°C to 280°C for 5 minut...

Embodiment 2

[0055] Embodiment 2 adopts following preparation method:

[0056] S100, mixing and stirring 22 parts of graphite powder in 20 parts of N-methylpyrrolidone;

[0057] S200, performing ultrasonic exfoliation on the mixture in S100 to obtain non-functionalized nano-graphene;

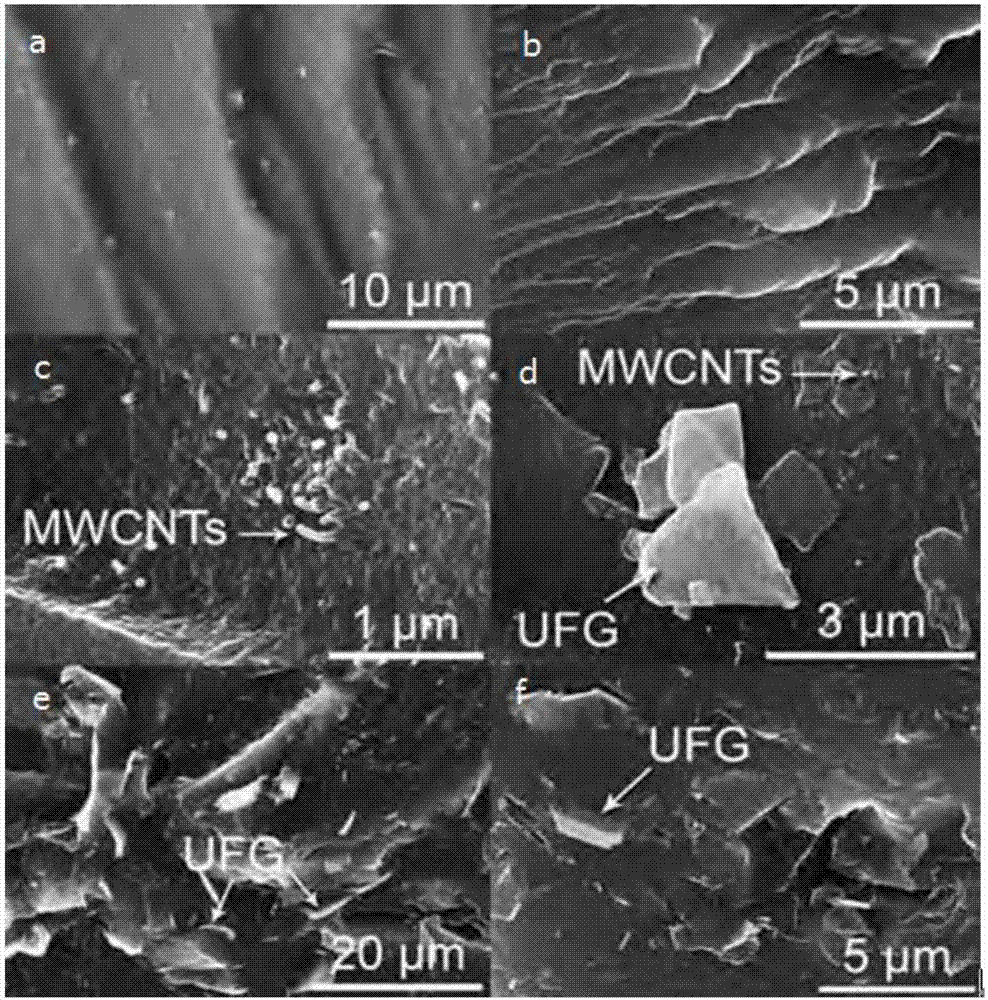

[0058] S300. Add 18 parts of phthalic anhydride and 20 parts of triethylenediamine to the non-functionalized graphene obtained in S200, and add 15 parts of multi-walled carbon nanotubes. After ultrasonic treatment at 80°C to 100°C for 5 minutes , mixing and stirring for 0.5h to 2.0h to carry out in-situ polymerization, wherein the acid anhydride and diamine are in-situ polymerized to form polyamic acid, and then the nano-graphene / polyamic acid mixture is obtained;

[0059] S400, the nanographene / polyamic acid mixture that S300 is obtained is evenly coated on the alloy steel surface of cleaning;

[0060] S500. After curing the alloy steel coated with nano-graphene / polyamic acid mixture at 150°C for 5 minute...

Embodiment 3

[0061] Embodiment 3 adopts following preparation method:

[0062] S100, mixing and stirring 25 parts of graphite powder in 32 parts of N-methylpyrrolidone;

[0063] S200, performing ultrasonic exfoliation on the mixture in S100 to obtain non-functionalized nano-graphene;

[0064] S300, adding 18 parts of diphenyl ether dianhydride and 18 parts of m-phenylenediamine to the non-functionalized graphene obtained in S200, and adding 15 parts of multi-walled carbon nanotubes, and ultrasonically treating at 80°C to 100°C for 5 minutes Afterwards, mix and stir for 0.5h to 2.0h for in-situ polymerization, in which acid anhydride and diamine are in-situ polymerized to form polyamic acid, then add 3 to 5 parts of m-phenylenediamine for stirring to obtain nano-graphene / polyamide Acid PAA mixture;

[0065] S400, the nanographene / polyamic acid mixture that S300 is obtained is evenly coated on the alloy steel surface of cleaning;

[0066] S500. After curing the alloy steel coated with nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com