Method for preparing novel hybrid fiber carbon paper for supercapacitor

A technology of supercapacitors and hybrid fibers, which is applied in the manufacture of hybrid/electric double-layer capacitors, pulping with inorganic alkali, and addition of inorganic compounds. It can solve the problems of low synthesis efficiency and general repeatability, and achieve broadened morphology. control, raw material rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

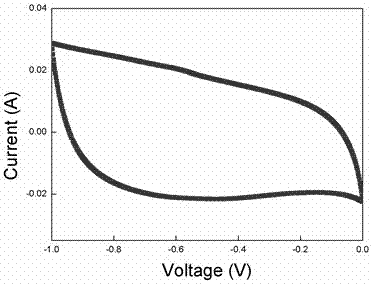

Image

Examples

preparation example Construction

[0028] The preparation method of the novel hybrid fiber carbon paper for supercapacitor comprises the following steps:

[0029] (1) Using wood as the precursor, through the papermaking process, the wood is cooked to form a slurry;

[0030] (2) The slurry is washed, screened, and beaten to form pulp, and then fiber paper is formed through the papermaking process of the sheet machine;

[0031] (3) Immerse the fiber paper in the electroless Ni plating solution, dry it after completing the metal loading reaction, and obtain the hybrid fiber paper;

[0032] (4) Under the protection of nitrogen, the obtained hybrid fiber paper is calcined at high temperature to form a new hybrid fiber carbon paper material; the obtained new hybrid fiber carbon paper material has certain electrical conductivity and electrochemical stability, and can be used in field of supercapacitors.

[0033] In the step (1), conifer or larch is used as the precursor, and the wood chips are cooked with 12%-18% so...

Embodiment 1

[0039] Larch was selected as the precursor, and wood chips were cooked with 12% sodium hydroxide solution at 180 °C for 4 h to form a slurry, then washed with deionized water until pH = 7, screened by a screener, and beaten to form pulp. The degree of beating is 60 °SR, and finally paper is formed through the papermaking process of a sheet machine, and the paper weight is 120 g / m2. The fiber paper was dipped in electroless Ni plating solution (100 mgNiSO 4 , 100 mg iminodiacetic acid, 200 μL 32% NaOH solution, 500 μL N 2 h 4 , 10 mL of deionized water) to complete metal loading, and react at 80 °C for 1 h. After drying at 100°C, the hybrid fiber paper was obtained, and then calcined at a calcination temperature of 700°C for 2 h under the protection of nitrogen to form a carbon material to obtain a new type of hybrid fiber carbon paper, which can be effectively used in supercapacitors.

Embodiment 2

[0041] Larch was selected as the precursor, and wood chips were cooked with 15% sodium hydroxide solution at 160 °C for 3 h to form a slurry, then washed with deionized water until pH = 7, screened by a screener, and beaten to form pulp. The degree of beating is 50 °SR, and finally paper is formed through the papermaking process of a sheet machine, and the basis weight of the paper is 100 g / m2. The fiber paper was dipped in electroless Ni plating solution (150 mgNiSO 4 , 150 mg iminodiacetic acid, 200 μL 32% NaOH solution, 600 μL N 2 h 4 , 20 mL of deionized water) to complete the metal loading, and reacted at 80 °C for 1 h. After drying at 90 °C, the hybrid fiber paper was obtained, and then calcined at 700 °C for 2 h under the protection of nitrogen to form a carbon material to obtain a new type of hybrid fiber carbon paper, which can be effectively used in supercapacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com