Water-soluble calcium stearate dispersion liquid and preparation method thereof

A calcium stearate dispersion, water-soluble technology, applied in fiber dispersant addition, paper forming aid addition, defoamer and other directions, can solve the problems of large amount of emulsifier, reduced viscosity, poor stability, etc. Good properties, high solid content and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

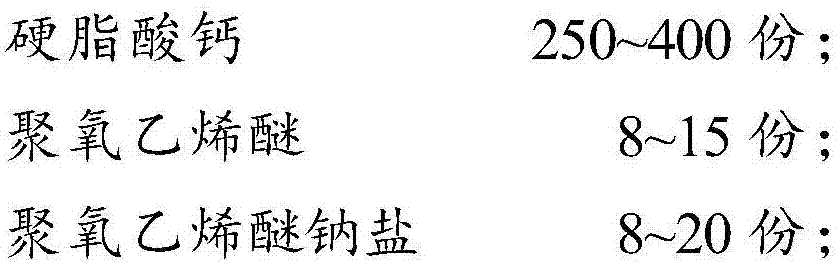

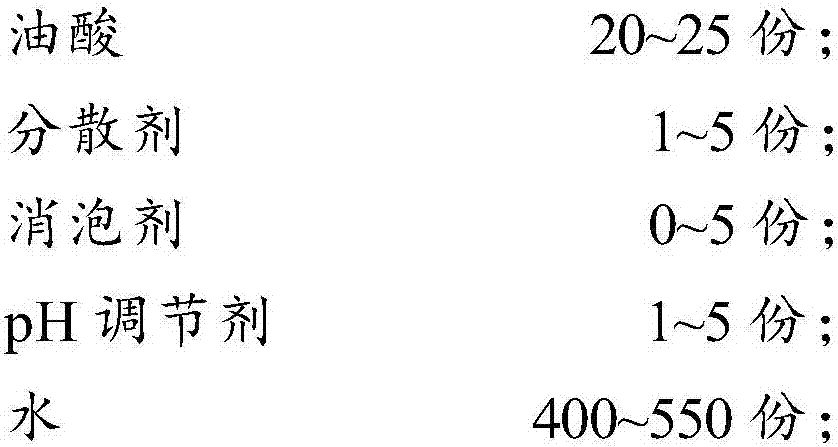

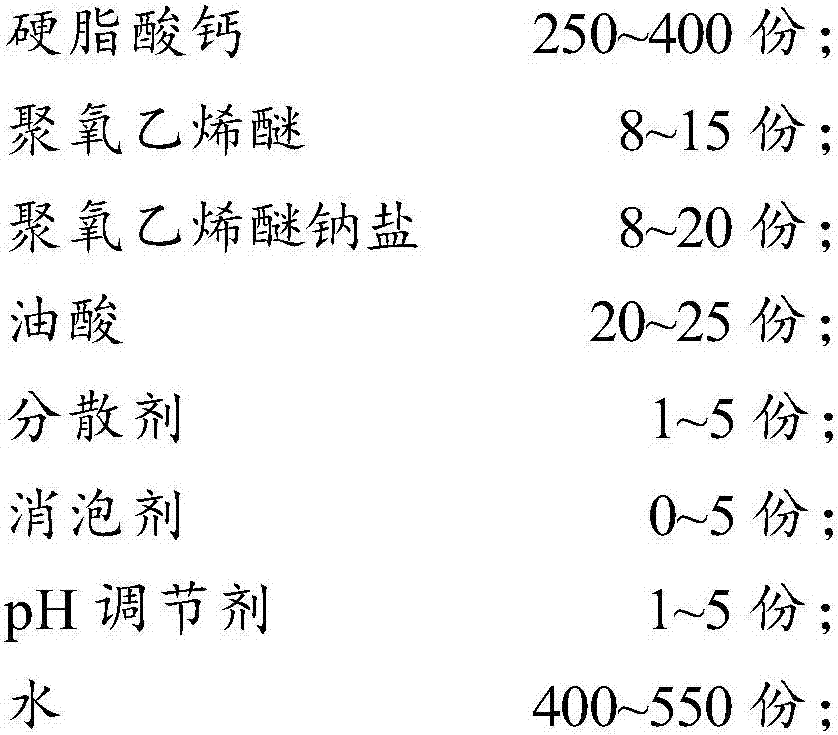

[0038] The present invention provides a kind of preparation method of water-soluble calcium stearate dispersion liquid described in above-mentioned technical scheme, comprises the following steps:

[0039] a) Calcium stearate, polyoxyethylene ether, polyoxyethylene ether sodium salt, oleic acid, dispersant, defoamer, pH regulator and water are mixed and then ground to obtain a water-soluble calcium stearate dispersion.

[0040] In the preparation method provided by the present invention, calcium stearate, polyoxyethylene ether, polyoxyethylene ether sodium salt, oleic acid, dispersant, defoamer, pH regulator and water are mixed according to the proportion and then ground Obtain described water-soluble calcium stearate dispersion liquid, this process specifically comprises:

[0041] a1), first mix polyoxyethylene ether, polyoxyethylene ether sodium salt, dispersant, pH regulator and oleic acid with part of water to obtain the first mixture;

[0042] a2), mixing the first mixtu...

Embodiment 1

[0048] In a 1L four-neck flask, add 310g of water, 10.5g of isomeric tridecyl alcohol polyoxyethylene ether (n=8), 15g of nonylphenol polyoxyethylene ether sulfonate (n=4), antifreeze dispersant BP -995 is 3g, oleic acid 22g, calcium hydroxide 3.5g, water-soluble silane defoamer (Guangdong Junxin Chemical Technology Co., Ltd., byfuel L85) 3.5g, stirring at 300r / min at room temperature (25°C) Stir at high speed to make it dissolve; after the dissolution is uniform, add 300g of calcium stearate, and stir at room temperature (25°C) at a stirring speed of 800r / min for 10min to wet the calcium stearate powder; then add 133g of water, Stir at a stirring speed of 200r / min for 20min at (25°C) to make it evenly mixed; finally, microgrind the above mixed material in a cone mill for 5min, and the obtained product is a white dispersion.

[0049] The obtained calcium stearate dispersion has a solid content of 45%, a rotational viscosity of 37CP at 25°C, a sieve residue (325 mesh)≤0.1%, and...

Embodiment 2

[0052] In a 1L four-neck flask, add 310g of water, 10.5g of isomeric tridecyl alcohol polyoxyethylene ether (n=8), 15g of fatty alcohol polyoxyethylene ether sodium sulfate (n=2), 3g of glycerin, 22g of oleic acid, Calcium hydroxide 3.5g, stir at room temperature (25°C) at a stirring speed of 300r / min to dissolve; after the dissolution is uniform, add 380g of calcium stearate, stir at room temperature (25°C) at a stirring speed of 800r / min 10min, calcium stearate powder is wetted; Then add the water of 133g, under room temperature (25 ℃) with the stirring speed of 200r / min stirring 20min, make it mix evenly; Grinding for 5 minutes, the resulting product is a white dispersion.

[0053] The obtained calcium stearate dispersion has a solid content of 50%, a rotational viscosity of 120CP at 25°C, a sieve residue (325 mesh)≤0.1%, and a pH of 10.3. Among the solids contained in the calcium stearate dispersion liquid, the particle content of 0.1 to 10 μm is 56.38 wt%, the content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com