Synthesis method of ball-flower shaped structure ZnO/ZnWO4 photocatalyst

A technology of photocatalyst and synthesis method, which is applied in the field of chemical industry to achieve the effect of uniform product, excellent hydrogen production performance and inhibition of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

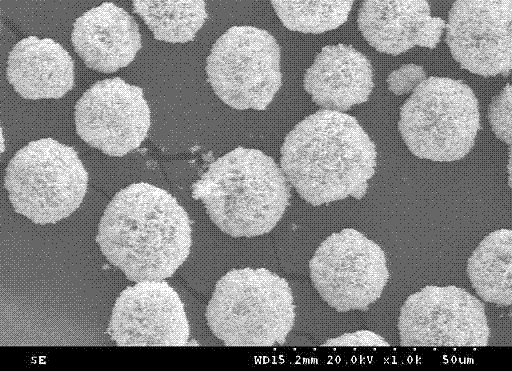

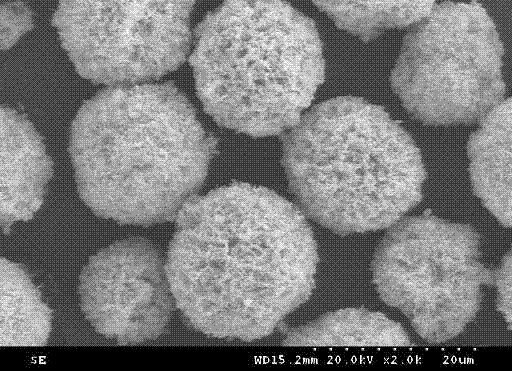

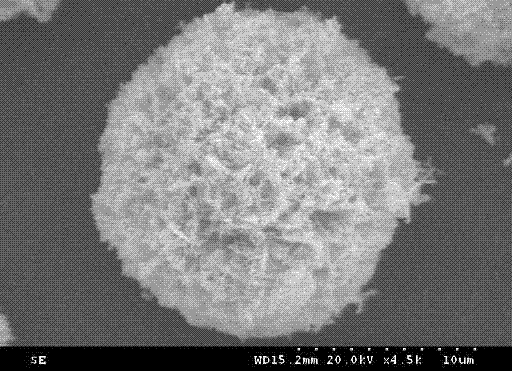

[0015] Flower spherical structure ZnO / ZnWO 4 Composite photocatalyst, take by weighing 99.5% sodium tungstate (Na 2 WO 3 2H 2 O), the quality is 1.6494 g, purchased from Tianjin Dongli District Tianda Chemical Reagent Factory 99.0% zinc nitrate (Zn(NO 3 )·6H 2 O), with a mass of 1.4875 g. Mix the above two chemical reagent raw materials into 30 mL deionized water, stir for 10 min, add ammonia water (NH 3 ·H 2 O), with a volume of 15 ± 1 drop, fully stirred and poured into a 100 mL polytetrafluoroethylene-lined microwave reactor, set the microwave hydrothermal reaction temperature at 180 ± 2 °C, and the reaction time at 150 ± 3 min. After the microwave radiation reaction is finished, the generated white precipitate is repeatedly washed with deionized water and absolute ethanol for 4-5 times respectively. Put the precipitate into the drying box, set the drying temperature at 60±2°C, and the drying time is 12+0.1h, and take it out to get the final product flower spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com