Aluminum nanometer particles and preparation method thereof

A technology of aluminum nano and particles, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high equipment requirements, poor particle shape uniformity, and difficult control of product shape, and achieve particle The effect of high content and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

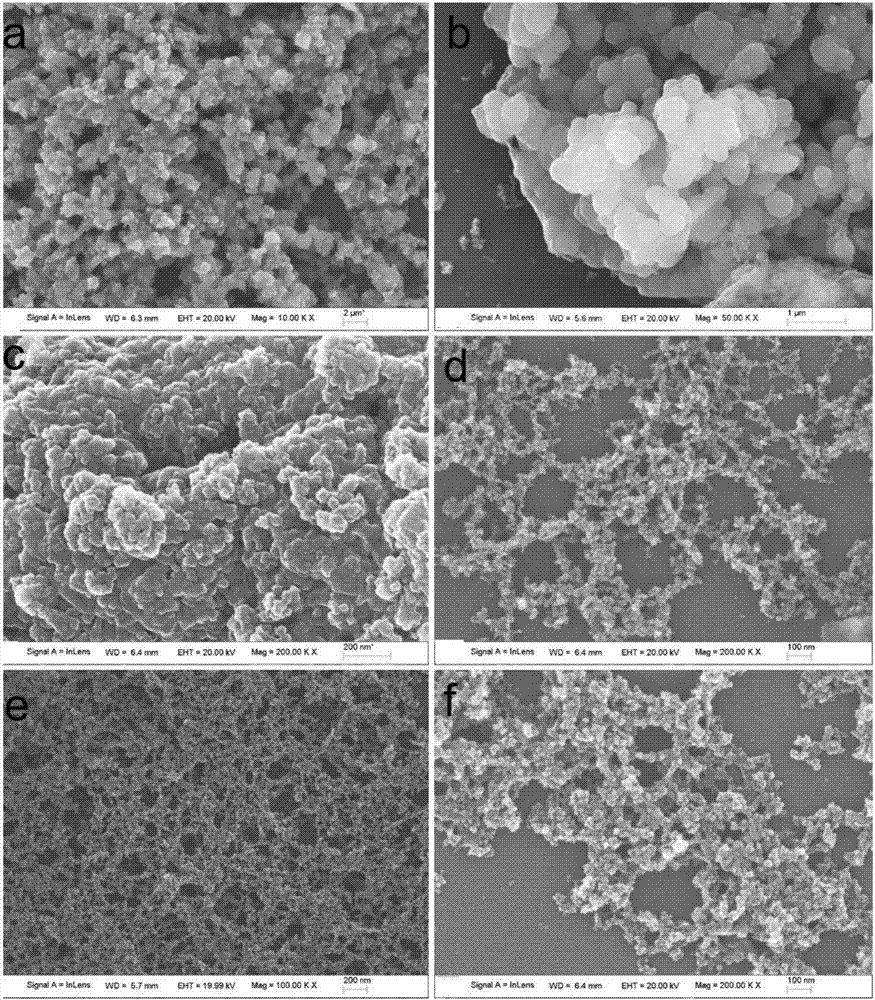

[0038] Add 0.10ml of aniline to 20ml of toluene after dehydration and oxygen removal, stir and mix well to form a mixed solution, and put it in a 50ml flask. Then add 0.13g of aluminum chloride powder into the mixed solution, raise the temperature to 80°C, stir well to completely dissolve the aluminum chloride, then add 0.075g of lithium aluminum hydride powder into the flask, stir vigorously to fully mix with the solution. The flask was placed in an oil bath at 120°C for 4 hours, then taken out and cooled naturally in air. Pour the cooled solution into a centrifuge tube and centrifuge at 8000rpm for 20min, remove the supernatant. Then disperse the concentrated suspension with 15 mL of acetone, ultrasonicate for 5 min, and centrifuge at 8000 rpm for washing; repeat the operation three times. Vacuum dried, isolated from oxygen and stored for later use. attached figure 1 a is the SEM image of the aluminum nanoparticles prepared in this example. The experimental result is: th...

Embodiment 2

[0040] Add 0.37ml of aniline to 20ml of toluene after dehydration and oxygen removal, stir and mix well to form a mixed solution, and put it in a 50ml flask. Then add 0.32g of aluminum acetylacetonate powder into the mixed solution, raise the temperature to 80°C, stir well to completely dissolve the aluminum chloride, then add 0.075g of lithium aluminum hydride powder into the flask, stir vigorously to fully mix with the solution. The flask was placed in an oil bath at 120°C for 4 hours, then taken out and left to cool naturally in the air. Pour the cooled solution into a centrifuge tube and centrifuge at 8000rpm for 20min, remove the supernatant. Then disperse the concentrated suspension with 15 mL of acetone, ultrasonicate for 5 min, and centrifuge at 8000 rpm for washing; repeat the operation three times. Vacuum dried, isolated from oxygen and stored for later use. attached figure 1b is the SEM image of the aluminum nanoparticles prepared in this example. The experiment...

Embodiment 3

[0042] Add 1ml of N-methylaniline to 20ml of toluene after dehydration and oxygen removal, stir and mix well to form a mixed solution, and put it in a 50ml flask. Then add 0.63g of aluminum chloride powder into the mixed solution, raise the temperature to 80°C, stir well to completely dissolve the aluminum chloride, then add 0.57g of lithium aluminum hydride powder into the flask, stir vigorously to fully mix with the solution. The flask was placed in an oil bath at 120°C for 4 hours, then taken out and cooled naturally in air. Pour the cooled solution into a centrifuge tube and centrifuge at 8000rpm for 20min, remove the supernatant. Then disperse the concentrated suspension with 15 mL of acetone, ultrasonicate for 5 min, and centrifuge at 8000 rpm for washing; repeat the operation three times. Vacuum dried, isolated from oxygen and stored for later use. attached figure 1 c is the SEM image of the aluminum nanoparticles prepared in this example. The experimental result is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com