A method for preparing one-dimensional nanomaterials with high aspect ratio by depolymerizing clay mineral crystal beams

A technology of clay minerals and high aspect ratio, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of one-dimensional nanosilicate materials that have no literature reports and no application precedents, etc., to solve the problem of preventing The effect of secondary reunion, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

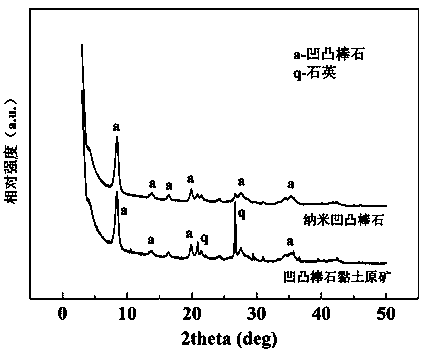

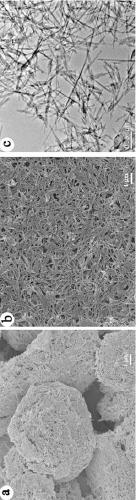

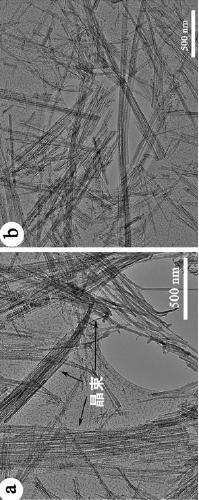

[0025] 100 kg of attapulgite raw ore was crushed and treated with rollers, and the water content of attapulgite raw ore was adjusted to 39% with hydrogen peroxide aqueous solution (mass fraction 1%); attapulgite raw ore was squeezed to obtain attapulgite with a thickness of 4 mm Stone raw ore flakes; the raw ore flakes were first frozen at -10°C for 12 hours, then thawed by microwave at 1000 W, 2450 MHz for 20 minutes, and then directly and evenly dispersed in methanol / water solution (volume percentage of methanol was 20%). After the mechanical stirring is uniform, the cyclone classification is carried out to remove the quartz sand and large particles, and then the high-pressure homogeneous treatment is performed under 60 MPa; the suspension obtained by the homogeneous treatment is hydraulically filtered to obtain a filter cake with a water content of 60%, and then extruded with a twin-screw extruded out of the machine, dried at 80°C, and crushed to obtain a white nano attapulg...

Embodiment 2

[0028]100 kg of sepiolite raw ore is crushed and treated with double rollers, adjusted to 39% water content of sepiolite raw ore with hydrogen peroxide solution (3% by mass), and seafoam with a thickness of 0.2 mm is obtained after extrusion treatment Raw stone ore flakes: Freeze the raw sepiolite flakes at -40°C for 2 h, then thaw them with 4000 W, 2450 MHz microwaves for 20 minutes, and then directly and evenly disperse them in ethanol / water solution (volume percentage of ethanol is 20%), mechanically stirred evenly, and then carried out cyclone classification treatment to remove quartz sand and large particles, and then high-pressure homogeneous treatment at 50 MPa; the obtained suspension hydraulic filtration obtained a filter cake with a water content of 60%, and then extruded with a twin-screw extruded out of the machine, dried at 80°C, and crushed to obtain a white nano sepiolite product.

[0029] When the obtained nano-sepiolite is dispersed in water at 10%, the sepiol...

Embodiment 3

[0031] 100 kg halloysite raw ore is crushed and treated with rollers, the water content of halloysite raw ore is adjusted to 35% with hydrogen peroxide solution (mass fraction 3%), and halloysite raw ore with a thickness of 1 mm is obtained by extrusion Thin slices: Freeze halloysite raw ore flakes at -30°C for 12 hours, then thaw them with 3000 W, 2450 MHz microwaves for 15 minutes, and then directly and evenly disperse them in 8% isopropanol / water solution (isopropanol volume percentage of 8%), mechanically stirred evenly, and then carried out cyclone classification to remove quartz sand and large particles, and then subjected to high-pressure homogenization treatment at 50 MPa, the obtained suspension was hydraulically filtered to obtain a filter cake with a water content of 45%, and then used Extruded by a twin-screw extruder, dried at 120° C., and pulverized to obtain a white nano halloysite product.

[0032] When the obtained nano halloysite is dispersed in water at 10%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com