1,4-hexaethyl butanediamine hydroxide, preparation method and application

A technology of butanediamine hydroxide and hexaethyldibromobutylamine, applied in 1 field, can solve problems such as high price, difficult preparation, unfavorable industrial production, etc., and achieve the effects of reducing synthesis price, simple synthesis process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

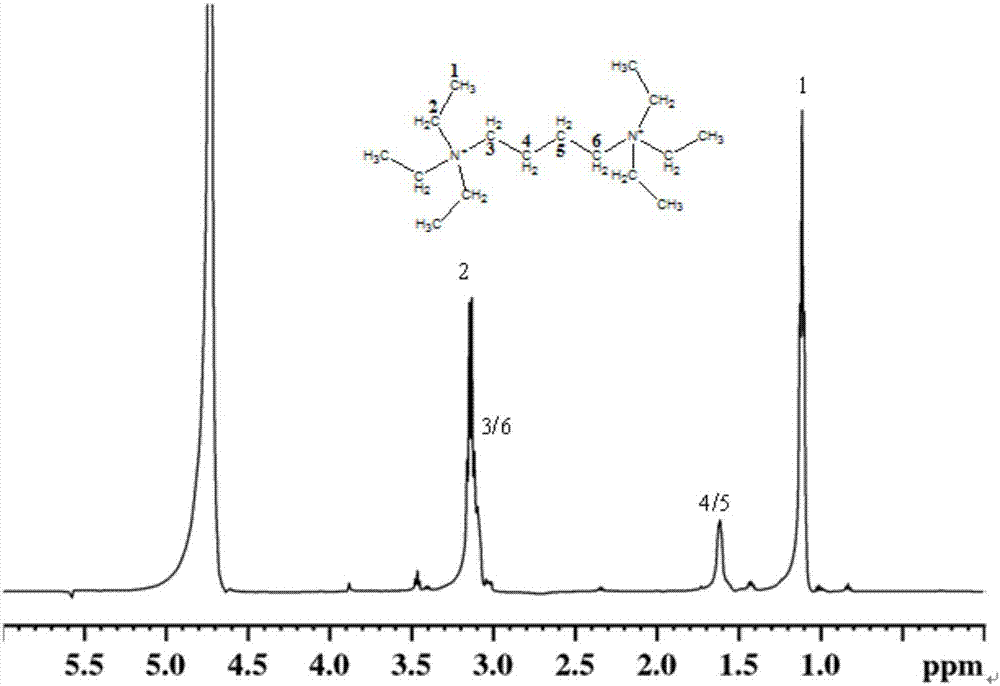

[0034] 1,4-hexaethylbutanediamine hydroxide (1,4-(C 2 h 5 ) 3 NC 4 h 8 N(C 2 h 5 ) 3 (OH) 2 ), its preparation method comprises:

[0035] 1) Mix triethylamine and 1,4-dibromobutane in acetone solution, heat under reflux for 24 hours to obtain a yellowish solid, wash the solid with acetone until white, and the obtained white solid is 1,4-hexaethyldi Bromobutylamine;

[0036]2) Dissolve the white solid powder of 1,4-hexaethyldibromobutylamine in water to obtain a clear solution, and obtain 1,4- Hexaethylbutylenediamine Hydroxide.

[0037] In step 1), the molar ratio of triethylamine to 1,4-dibromobutane is 2.4:1, and the molar ratio of triethylamine to acetone is 0.5:1;

[0038] In step 2), the molar ratio of water to 1,4-hexaethyldibromobutylamine is 60:1;

[0039] The production cycle of the above method for preparing 1,4-hexaethyl butanediamine hydroxide is no more than 48 hours, and the yield of 1,4-hexaethyl dibromobutylamine is 86%. 1,4-hexaethyl hydroxide The...

Embodiment 2

[0041] 1,4-hexaethylbutanediamine hydroxide (1,4-(C 2 h 5 ) 3 NC 4 h 8 N(C 2 h 5 ) 3 (OH) 2 ), its preparation method comprises:

[0042] 1) Mix triethylamine and 1,4-dibromobutane in acetone solution, heat under reflux for 24 hours to obtain a yellowish solid, wash the solid with acetone until white, and the obtained white solid is 1,4-hexaethyldi Bromobutylamine;

[0043] 2) Dissolve the white solid powder of 1,4-hexaethyldibromobutylamine in water to obtain a clear solution, and obtain 1,4- Hexaethylbutylene diamine hydroxide ( figure 1 ), for Examples 4-7.

[0044] In step 1), the molar ratio of triethylamine to 1,4-dibromobutane is 2.2:1, and the molar ratio of triethylamine to acetone is 0.5:1;

[0045] In step 2), the molar ratio of water to 1,4-hexaethyldibromobutylamine is 65:1;

[0046] The above-mentioned method prepares 1, the production period of 4-hexaethyl butanediamine hydroxide is no more than 48 hours, and the productive rate of 1, 4-hexaethyl di...

Embodiment 3

[0048] 1,4-hexaethylbutanediamine hydroxide (1,4-(C 2 h 5 ) 3 NC 4 h 8 N(C 2 h 5 ) 3 (OH) 2 ), its preparation method comprises:

[0049] 1) Mix triethylamine and 1,4-dibromobutane in acetone solution, heat under reflux for 24 hours to obtain a yellowish solid, wash the solid with acetone until white, and the obtained white solid is 1,4-hexaethyldi Bromobutylamine;

[0050] 2) Dissolve the white solid powder of 1,4-hexaethyldibromobutylamine in water to obtain a clear solution, and obtain 1,4- Hexaethylbutylenediamine Hydroxide.

[0051] In step 1), the molar ratio of triethylamine to 1,4-dibromobutane is 2.0:1, and the molar ratio of triethylamine to acetone is 0.8:1;

[0052] In step 2), the molar ratio of water to 1,4-hexaethyldibromobutylamine is 100:1;

[0053] The production cycle of the above method for preparing 1,4-hexaethyl butanediamine hydroxide is no more than 48 hours, and the yield of 1,4-hexaethyl dibromobutylamine is 80%. 1,4-hexaethyl hydroxide T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com