Method for rapidly preparing photonic crystal hydrogel bilayer film capable of changing color by stretching in large area

A technology of photonic crystals and hydrogels, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of incapable of large-scale preparation, small change range, cumbersome process, etc., and achieve easy promotion and application, the effect of adjusting the wavelength range is wide, and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

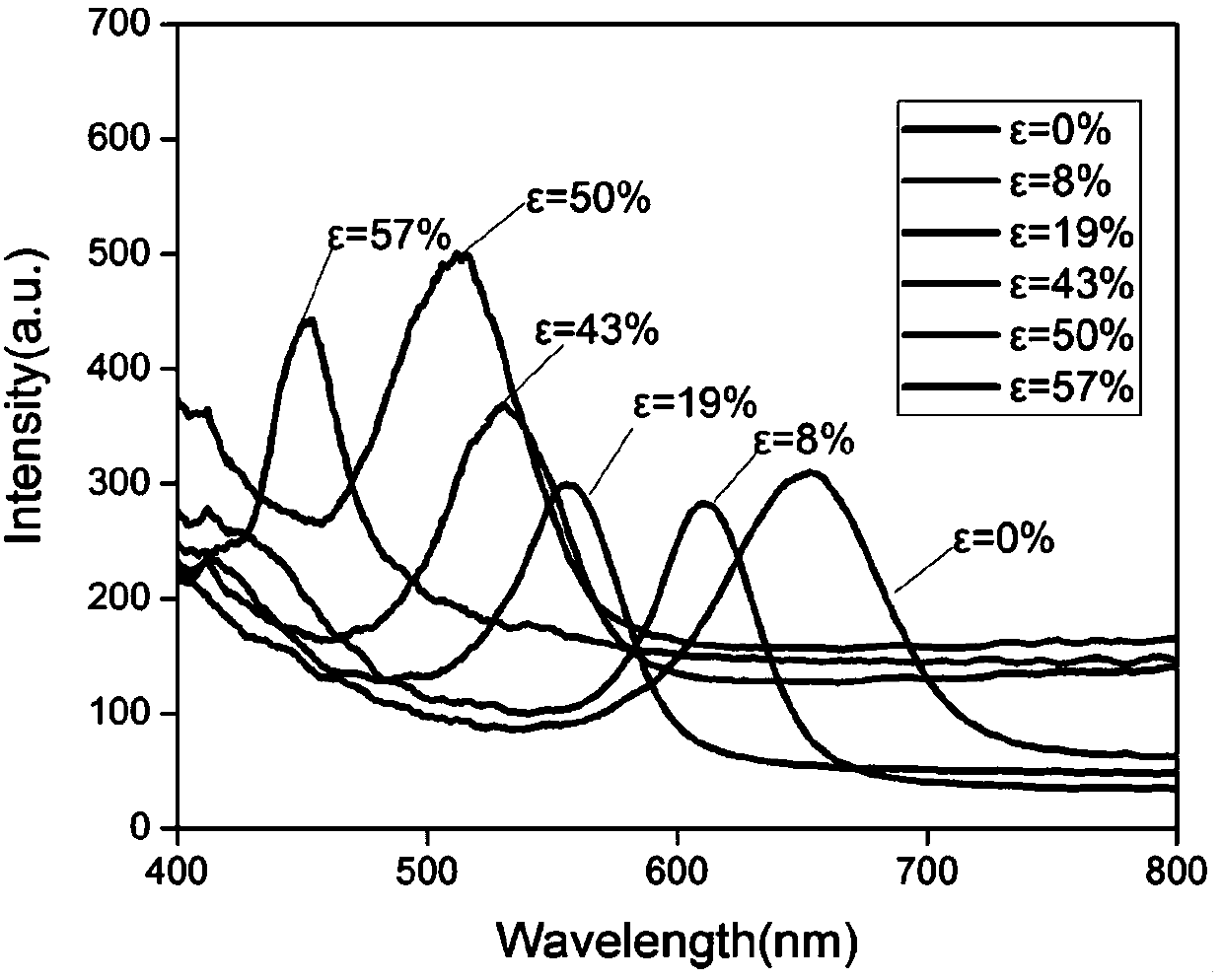

[0027] A large-area rapid preparation method for the preparation of a stretched color-changing photonic crystal hydrogel double-layer film of the present application specifically includes the following steps:

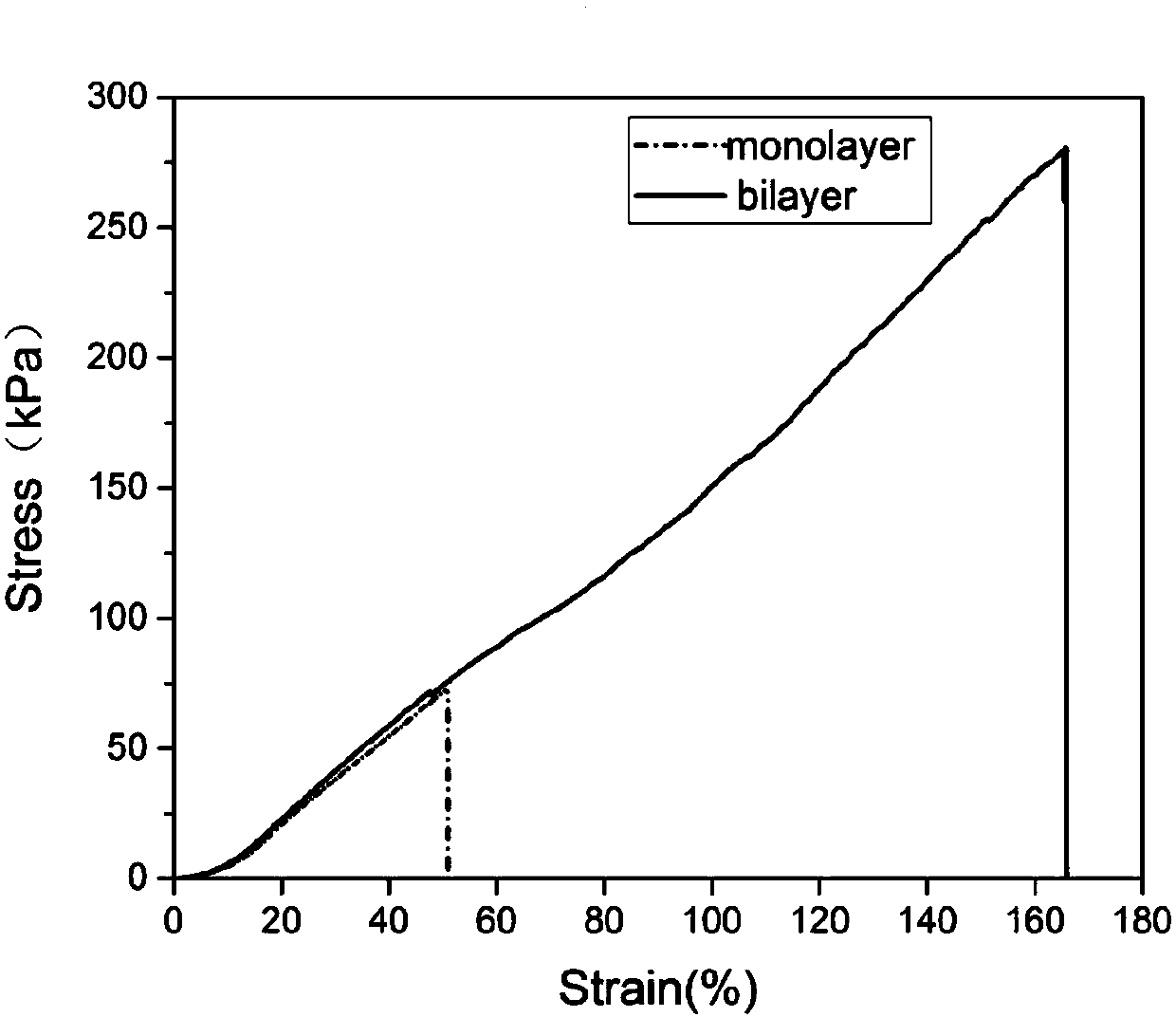

[0028] (1) 8g styrene, 1g methyl methacrylate and 1g acrylic acid prepare high concentration (50wt%) composite microspheres by emulsion polymerization, then add 0.25g acrylamide and 0.015g N, N-methylenebisacrylamide In a centrifuge tube equipped with 5g of high-concentration composite microspheres (50wt%), after mixing evenly, pour it into two glass plates of 20×20cm with 0.06mm thick rubber gaskets, and induce polymerization for 30min by ultraviolet light to obtain photons Crystalline hydrogel monolayers.

[0029] (2) 10.0g of zirconia sol with a mass fraction of 15%, 0.32g of acrylic acid, and 4.0g of N,N-dimethylacrylamide were added to a 50mL reaction flask containing 6.5g of ultrapure water, and stirred under magnetic force Nitrogen was passed for 20 minutes, 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com