A five-element rare earth boride single crystal hot cathode material and its preparation method

A technology of rare earth borides and hot cathodes, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth. It can solve the problems of small single crystal size, achieve good thermal emission performance and ensure high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment prepares five elemental rare earth borides (Ce 0.4 La 0.2 PR 0.2 Nd 0.2 )B 6 Single crystal:

[0023] (1) CeB with a purity of not less than 99.9% and a particle size of less than 360 mesh 6 、LaB 6 , PrB 6 、NdB 6 The powder is used as the raw material, and it is evenly mixed and dried by ball milling at a molar ratio of 2:1:1:1. The resulting mixed powder is placed in a graphite mold, pre-pressed (at a pressure of 10MPa), and then placed in the cavity of a spark plasma sintering furnace. Vacuumize until the vacuum degree is not higher than 5Pa, apply an axial pressure of 40MPa, heat up to 1700°C, and hold for 5 minutes; after completion, cool with the furnace, take out the sample when the furnace temperature is not higher than 50°C, and obtain a polycrystalline sample;

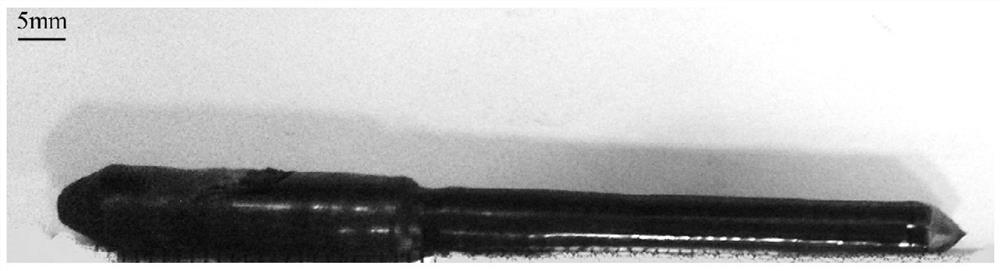

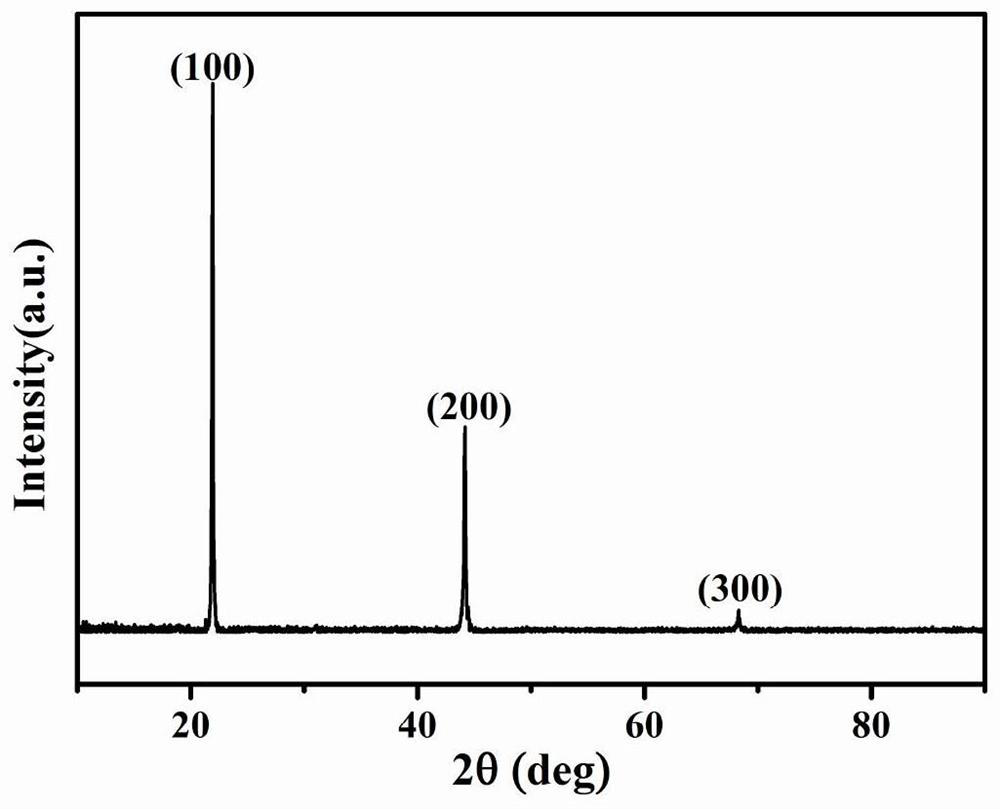

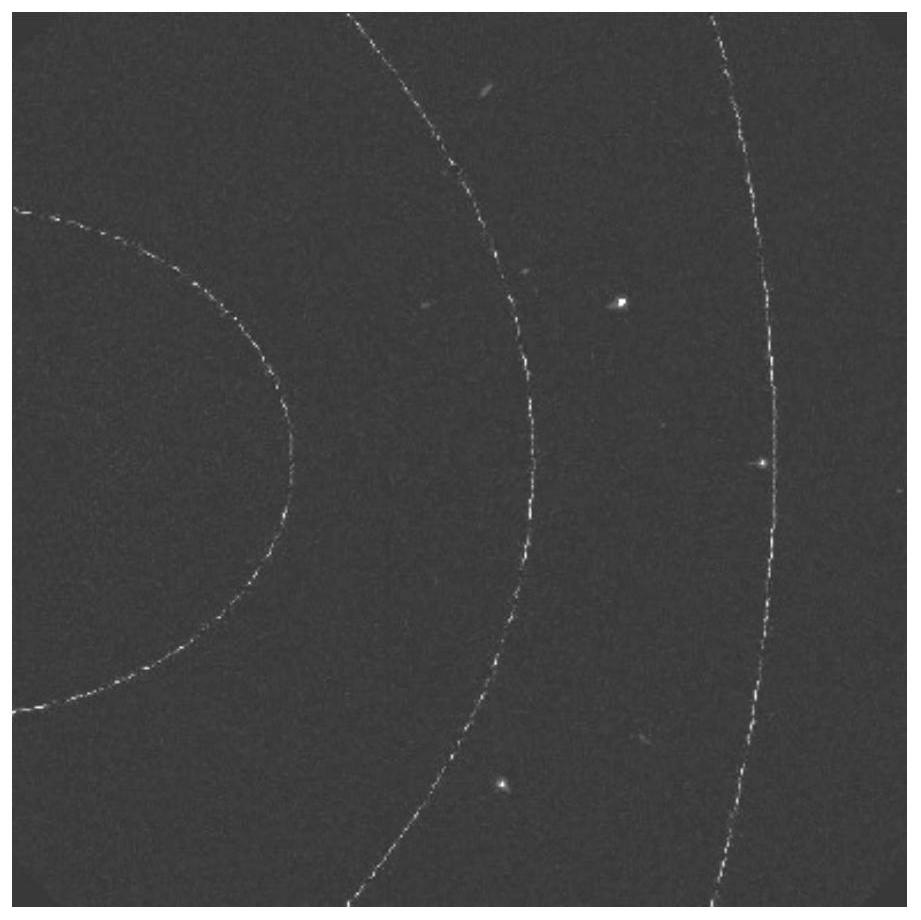

[0024] (2) Cut the polycrystalline sample into a polycrystalline test rod with a diameter of Ф6mm by using a wire electric discharge machine. The rods were placed in an e...

Embodiment 2

[0031] The present embodiment prepares five elemental rare earth borides (Ce 0.7 La 0.1 PR 0.1 Nd 0.1 )B 6 Single crystal:

[0032] (1) CeB with a purity of not less than 99.9% and a particle size of less than 360 mesh 6 、LaB 6 , PrB 6 、NdB 6 The powder is used as the raw material, and it is evenly mixed and dried by ball milling at a molar ratio of 7:1:1:1. The resulting mixed powder is placed in a graphite mold, pre-pressed (at a pressure of 10MPa), and then placed in the cavity of a spark plasma sintering furnace. Vacuumize until the vacuum degree is not higher than 5Pa, apply an axial pressure of 40MPa, heat up to 1700°C, and hold for 5 minutes; after completion, cool with the furnace, take out the sample when the furnace temperature is not higher than 50°C, and obtain a polycrystalline sample;

[0033] (2) Cut the polycrystalline sample into a polycrystalline test rod with a diameter of Ф6mm by using a wire electric discharge machine. The rods were placed in an e...

Embodiment 3

[0038] The present embodiment prepares five elemental rare earth borides (Ce 0.55 La 0.15 PR 0.15 Nd 0.15 )B 6 Single crystal:

[0039] (1) CeB with a purity of not less than 99.9% and a particle size of less than 360 mesh 6 、LaB 6 , PrB 6 、NdB 6 The powder is used as the raw material, and it is evenly mixed and dried by ball milling at a molar ratio of 11:3:3:3. The resulting mixed powder is put into a graphite mold, pre-pressed (10MPa pressure), and then placed in the cavity of a spark plasma sintering furnace. Vacuumize until the vacuum degree is not higher than 5Pa, apply an axial pressure of 40MPa, heat up to 1700°C, and hold for 5 minutes; after completion, cool with the furnace, take out the sample when the furnace temperature is not higher than 50°C, and obtain a polycrystalline sample;

[0040] (2) Cut the polycrystalline sample into a polycrystalline test rod with a diameter of Ф6mm by using a wire electric discharge machine. The rods were placed in an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com