Preparation methods of acid-doped pyrrole-m-toluidine copolymer and modified anticorrosive coating

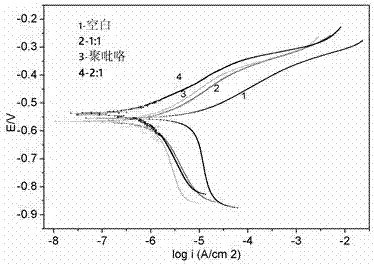

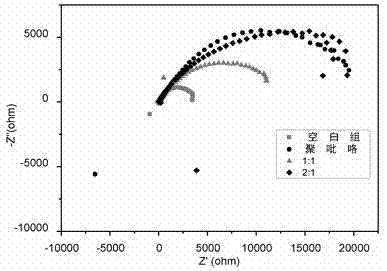

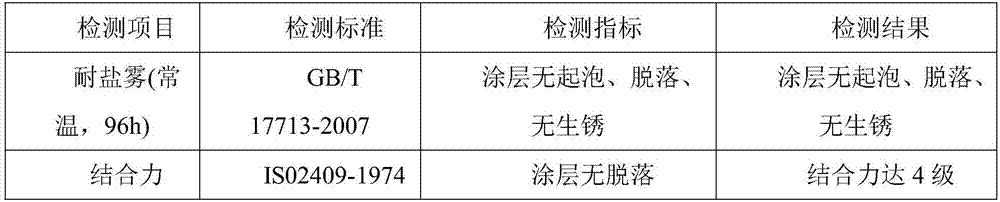

An anti-corrosion coating and toluidine technology, applied in the field of material engineering, can solve the problems of poor thermal stability and chemical stability, poor anti-corrosion performance, etc., and achieve the effects of good corrosion resistance, good anti-corrosion performance and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Paint preparation:

[0025] Take 10g epoxy resin in beaker with electronic balance; Add 1-methyl-2-pyrrolidone (diluent) of 1g in epoxy resin and stir with glass rod; Add 0.6g ethylenediamine (curing agent) in beaker ), and stir evenly to obtain pure epoxy resin coating. And then evenly coated on Q235 carbon steel.

Embodiment 2

[0027] 1. Preparation of polypyrrole:

[0028] ① Weigh ammonium persulfate and deionized water to make 0.4M ammonium persulfate solution, set aside;

[0029] ②Pyrrole monomer and m-toluidine monomer are added dropwise into a clean beaker at a volume ratio of 1:0 (1=0.5ml);

[0030] ③Add 10ml of 0.5M citric acid to the beaker in step ②, then put it into an ultrasonic cleaner and shake for 5-8 minutes, so that there is a layer of white transparent oil on the surface;

[0031] ④ Take out the beaker of step ③ and slowly add 5ml of the ammonium persulfate solution prepared in step ①, and shake the beaker while adding, the reaction is rapid, and the color of the solution gradually changes from colorless and transparent to purple red and finally to purple black;

[0032] ⑤ Seal the beaker with plastic wrap, place it at room temperature, and let it stand for 20-24 hours;

[0033] ⑥ Cross-wash with deionized water and absolute ethanol, and perform suction filtration while washing to ...

Embodiment 3

[0041] 1. Preparation of acid-doped pyrrole-m-toluidine copolymer:

[0042] ① Weigh ammonium persulfate and deionized water to make 0.4M ammonium persulfate solution, set aside;

[0043] ② Add dropwise monomers and m-toluidine monomers into a clean beaker at a volume ratio of 1:1 (1=0.5ml);

[0044] ③Add 10ml of 0.5M citric acid to the beaker in step ②, then put it into an ultrasonic cleaner and shake it for 5-8 minutes, so that there is a layer of white transparent oil on the surface;

[0045] ④ Take out the beaker of step ③ and slowly add 5ml of the ammonium persulfate solution prepared in step ①, and shake the beaker while adding, the reaction is rapid, and the color of the solution gradually changes from colorless and transparent to purple red and finally to purple black;

[0046] ⑤ Seal the beaker with plastic wrap, place it at room temperature, and let it stand for 20-24 hours;

[0047] 6. Cross-wash with deionized water and absolute ethanol, and carry out suction filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com