Compound calcium sulfonate grease and preparation method thereof

A compound calcium sulfonate based grease and compound calcium sulfonate technology are applied in the field of lubricating grease, which can solve the problems such as surface hardening of compound calcium sulfonate based grease, environmental impact on the production site, loss of fluidity of materials, etc., so as to eliminate hardening. problems, shorten production times, avoid incomplete conversion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

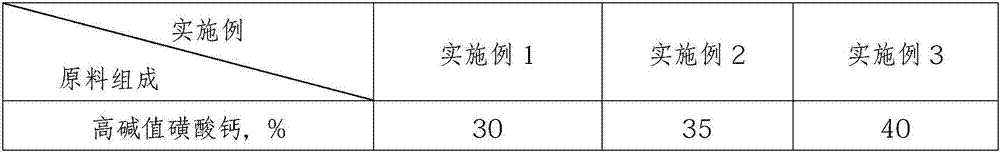

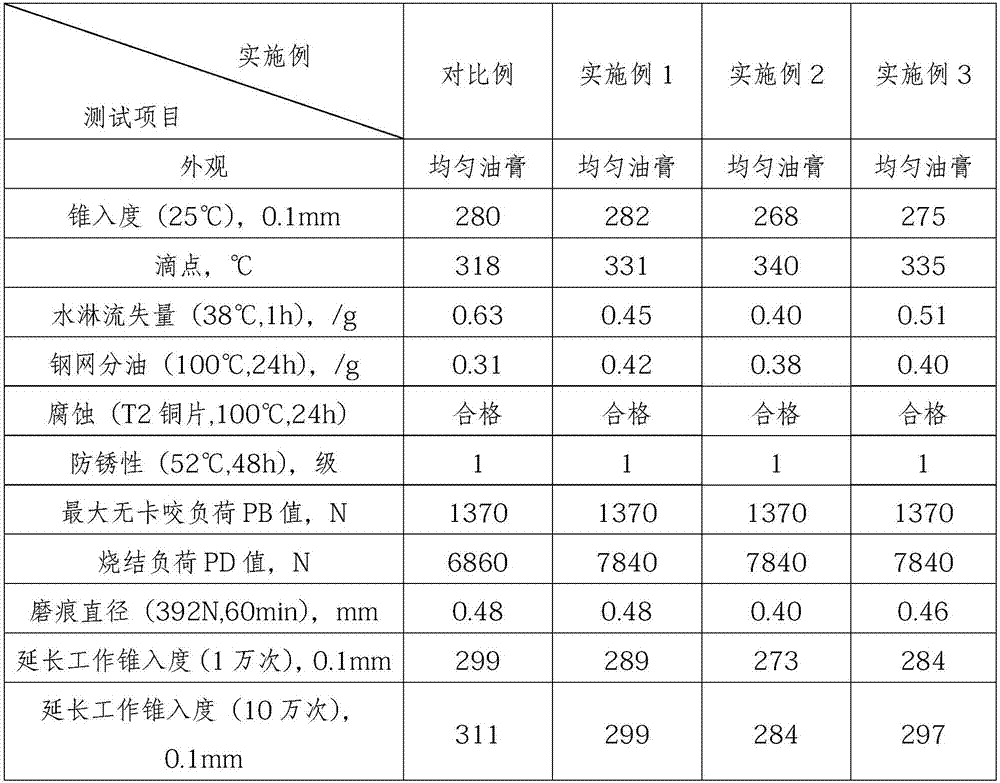

Embodiment 1

[0061] Add 30kg of T106D calcium sulfonate with high base value and 1 / 3 of base oil KL-115 into the autoclave, and stir evenly. Add the micropowder calcium carbonate of 1kg, the water of 5kg, the isopropanol of 2.0kg and the dodecylsulfonic acid of 1.5kg in the autoclave simultaneously. Tighten the lid and seal the autoclave. Raise the temperature of the autoclave to 80-100° C., and the pressure to 0.2-0.3 MPa. Cool and reflux at this temperature and pressure for 0.5 to 1.5 hours. Continue to heat up the autoclave to 105-110°C. Turn on the vacuum pump to evacuate to remove the conversion agent and water. The lid of the autoclave was opened, and 1 / 3 of base oil KL-115, 4.0 kg of calcium hydroxide emulsion, 3.0 kg of boric acid aqueous solution and 4.0 kg of 12-hydroxystearic acid were added again. Seal the autoclave, continue to heat up to 110-185°C, and keep warm for 0.5-1.5h. Open the pressure relief valve, continue to heat up to 200-260 ° C, keep the temperature constan...

Embodiment 2

[0063] Add 35kg of T106D calcium sulfonate with high base value and 1 / 3 of base oil KL-115 into the autoclave, and stir evenly. Add the micropowder calcium carbonate of 1kg, the water of 5kg, the isopropanol of 2.5kg and the dodecylsulfonic acid of 2.0kg in the autoclave simultaneously. Tighten the lid and seal the autoclave. Raise the temperature of the autoclave to 80-100° C., and the pressure to 0.2-0.3 MPa. Cool and reflux at this temperature and pressure for 0.5 to 1.5 hours. Continue to heat up the autoclave to 105-110°C. Turn on the vacuum pump to evacuate to remove the conversion agent and water. The lid of the autoclave was opened, and 1 / 3 of base oil KL-115, 4.5kg of calcium hydroxide emulsion, 3.5kg of boric acid aqueous solution and 4.5kg of 12-hydroxystearic acid were added again. Seal the autoclave, continue to heat up to 110-185°C, and keep warm for 0.5-1.5h. Open the pressure relief valve, continue to heat up to 200-260 ° C, keep the temperature constant f...

Embodiment 3

[0065] Add 40kg of T106D calcium sulfonate with high base value and 1 / 3 of base oil KL-115 into the autoclave, and stir evenly. Add the micropowder calcium carbonate of 1kg, the water of 5kg, the Virahol of 3.0kg and the dodecylsulfonic acid of 2.5kg in the autoclave simultaneously. Tighten the lid and seal the autoclave. Raise the temperature of the autoclave to 80-100° C., and the pressure to 0.2-0.3 MPa. Cool and reflux at this temperature and pressure for 0.5 to 1.5 hours. Continue to heat up the autoclave to 105-110°C. Turn on the vacuum pump to evacuate to remove the conversion agent and water. The lid of the autoclave was opened, and 1 / 3 of base oil KL-115, 5.0 kg of calcium hydroxide emulsion, 4.0 kg of boric acid aqueous solution and 5.0 kg of 12-hydroxystearic acid were added again. Seal the autoclave, continue to heat up to 110-185°C, and keep warm for 0.5-1.5h. Open the pressure relief valve, continue to heat up to 200-260 ° C, keep the temperature constant fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com