Catalyst for electrochemical reduction of carbon dioxide and preparation method of catalyst

A carbon dioxide and catalyst technology, applied in the field of electrochemical carbon dioxide reduction catalyst and its preparation, can solve the problems of complex catalyst structure control, low conversion current efficiency, unfavorable catalyst scale, etc., and achieve good CO2 electroreduction catalytic activity and CO2 conversion The effect of high efficiency and good process scale-up ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

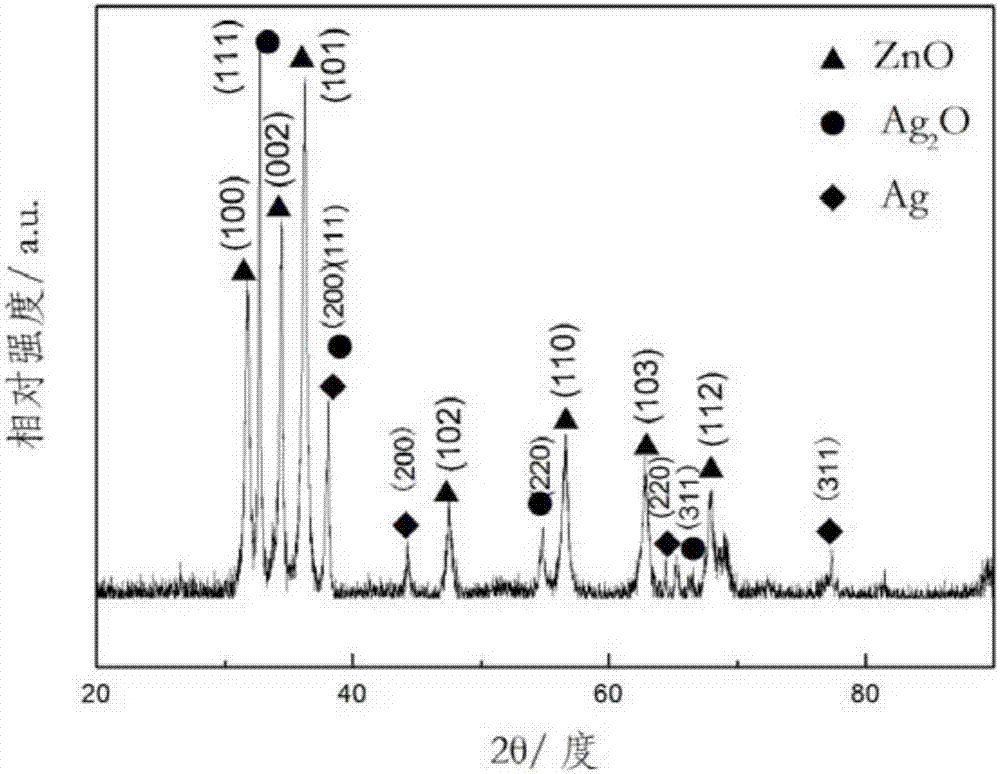

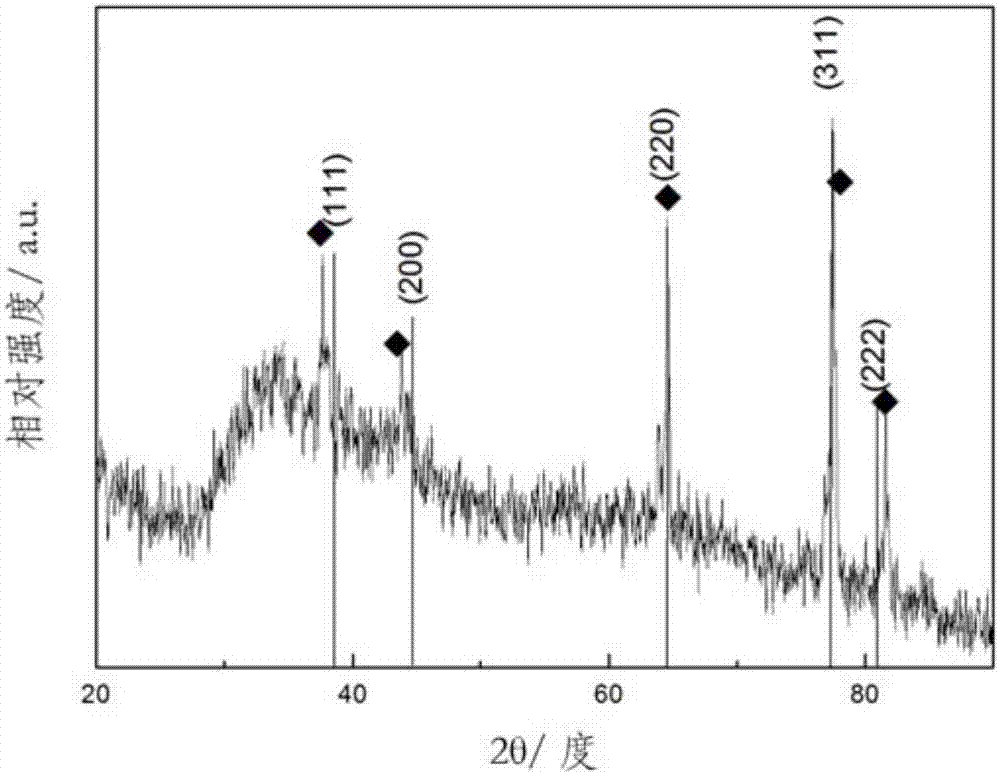

[0022] Carbon supported nano Ag x Zn y o z (0<x<1, 0<y<1, x+y=1, z≤2x+y) catalyst preparation method, comprising the following steps: S1: weighing soluble zinc source compound and silver source compound by molar ratio, The zinc source compound and the silver source compound are dissolved in deionized water to prepare a precursor solution. S2: adding the carbon support to the precursor solution and dispersing evenly. S3: Prepare a strong base solution and add it to the carbon black / precursor solution. After the reaction is completed, filter to separate solid particles, wash, dry, grind, and finally roast to obtain the catalyst.

[0023] Wherein the soluble zinc source compound may be zinc chloride, zinc sulfate, zinc nitrate, zinc acetate and the like. The soluble silver source compound may be silver nitrate or the like. Substances that can be used as carbon supports include carbon black, acetylene black, Ketjen black, carbon nanofibers, carbon nanotubes, and the like. Th...

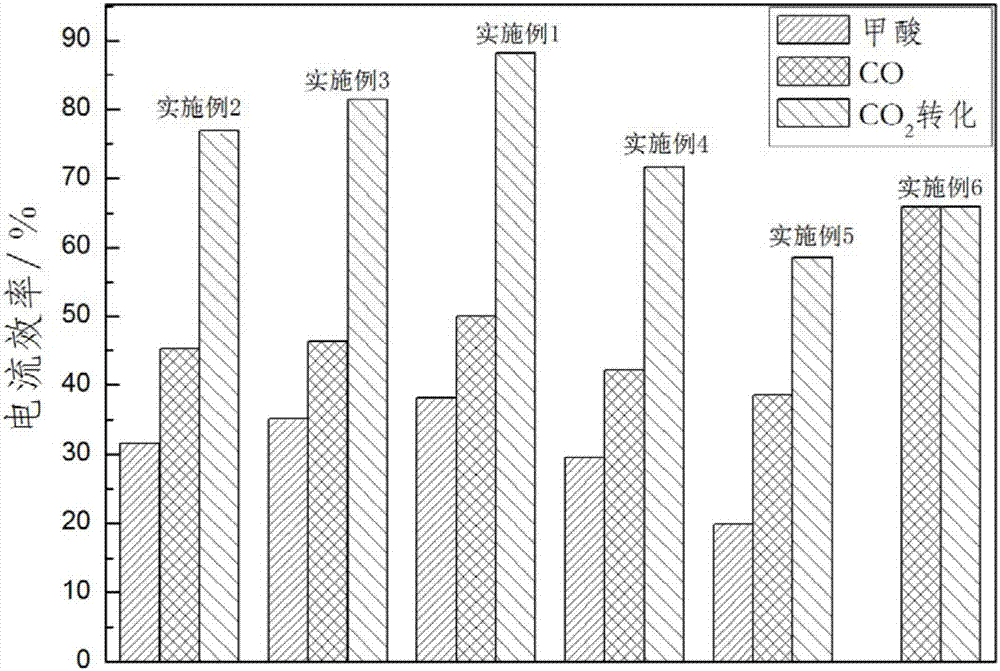

Embodiment 1

[0028] According to zinc element and silver element molar ratio is 85:15 scale removes zinc nitric acid and silver nitrate. 5.1 g of zinc nitrate hexahydrate and 0.5 g of silver nitrate were stirred and dissolved in 200 mL of deionized water to prepare a precursor solution. Add 0.4g of carbon black (XC-72) to the precursor solution, and sonicate for 10min until uniformly dispersed. Weigh 1.8g of sodium hydroxide and make 1mol L -1 Sodium hydroxide solution, with a syringe pump at 1mL·min -1Added dropwise into the precursor solution containing carbon black at a speed of Keep the reaction temperature at about 25°C, and magnetically stir the precursor solution during the dropwise addition. During the dropwise addition, the pH value of the reaction system was monitored with a pH meter, and the pH was kept increasing slowly. Continue stirring for 3h after the dropwise addition. Then use a vacuum filter to separate the solid particles, wash them three times with deionized water...

Embodiment 2

[0030] Except that the zinc nitrate and the silver nitrate that take zinc element and silver element molar ratio are 99:1 by weighing, other conditions are identical with embodiment 1. The obtained product catalyst is Zn 0.99 Ag 0.01 o z / C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com