Method of growing porous nickel cobaltate nanosheets based on hollow carbon sphere template

A hollow carbon sphere and nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as lack of preparation methods and single preparation methods, and achieve low equipment requirements and preparation methods. Simple, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

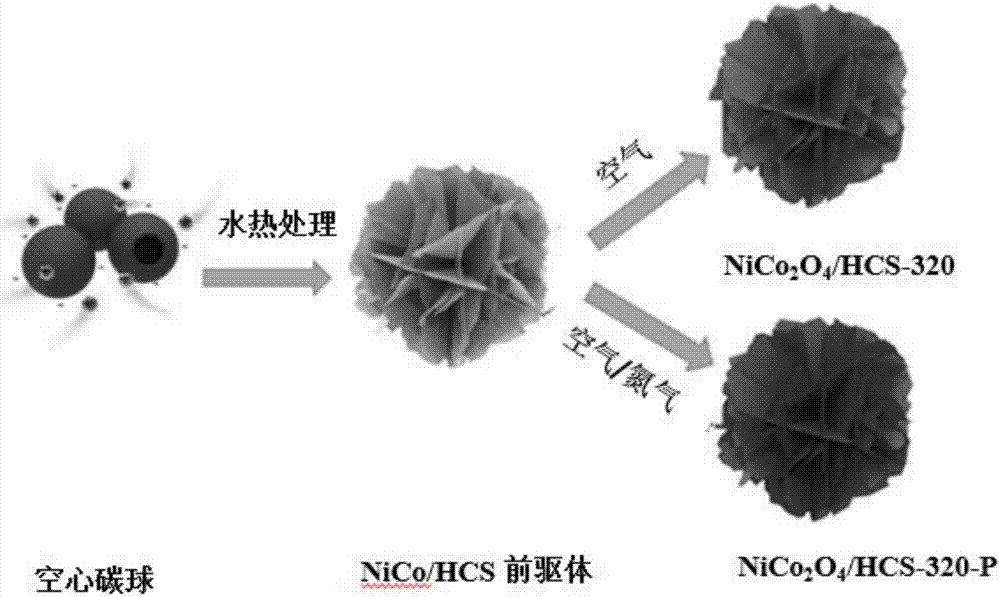

[0046] Example 1, see figure 1 , 2 , 3, 6, 7, 8:

[0047] The invention provides a kind of method based on hollow carbon sphere template growth porous nickel cobalt oxide nanosheet, comprises the following steps (see figure 1 ):

[0048] 1. Synthesis of hollow carbon spheres:

[0049] 1) Mix 20mL of deionized water, 60mL of absolute ethanol and 3mL of ammonia water (28wt.%), add 0.4g of resorcinol, and stir until dissolved; after stirring continuously for 10min, add 2.8mL of tetraethyl orthosilicate, continue After stirring for 10 min, add 0.56 mL of formaldehyde (36 wt.%), and stir at room temperature for 24 h;

[0050] 2) Transfer the above solution to a 100mL autoclave, place the autoclave in an oven at 100°C, conduct a hydrothermal reaction for 24 hours, take out the autoclave and cool to room temperature naturally;

[0051] 3) Centrifuge the hydrothermal product, wash the solid phase substance with deionized water for 3 times, and wash with absolute ethanol for 3 times...

Embodiment 2

[0065] Example 2, see figure 1 , 2 , 4-8:

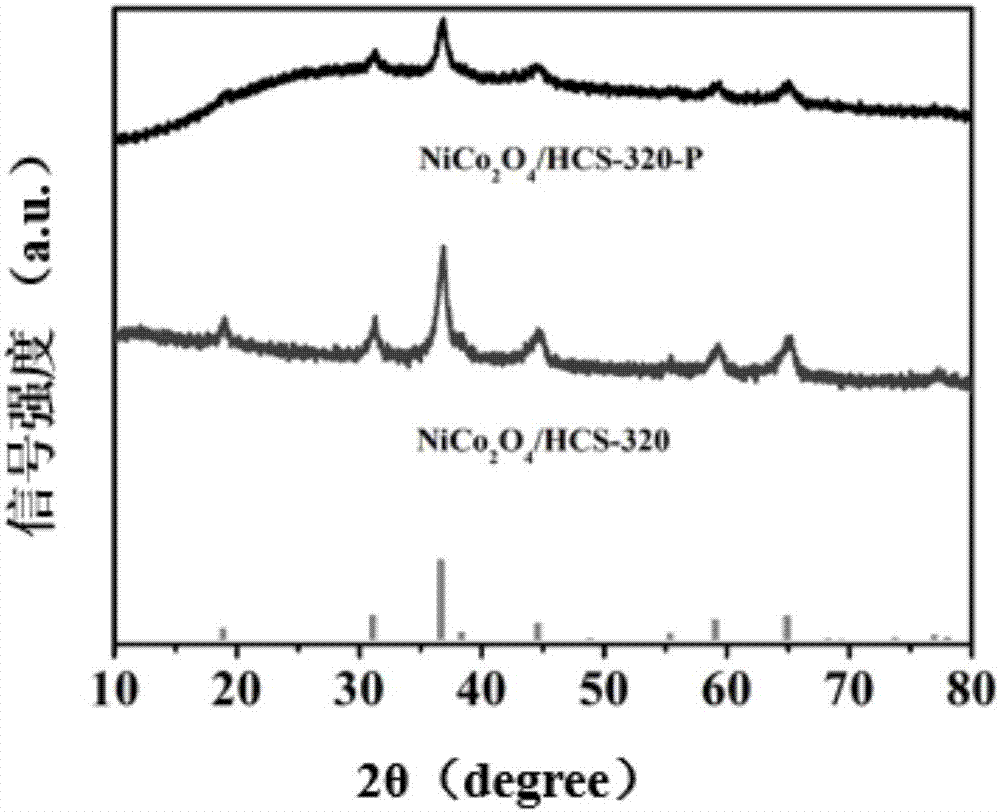

[0066] The present invention provides a method for growing porous nickel cobaltate nanosheets rich in oxygen vacancies based on a hollow carbon sphere template, which is basically the same as in Example 1, except that during heat treatment of the composite, nitrogen / air (volume ratio: 9:1) under the atmosphere, the temperature was raised to 320°C at a rate of 5°C / min, and kept for 2h, and then cooled to room temperature with the furnace, and a porous nickel cobaltate nanosheet / hollow carbon sphere composite rich in oxygen vacancies was obtained. Named NiCo 2 o 4 / HCS-320-P.

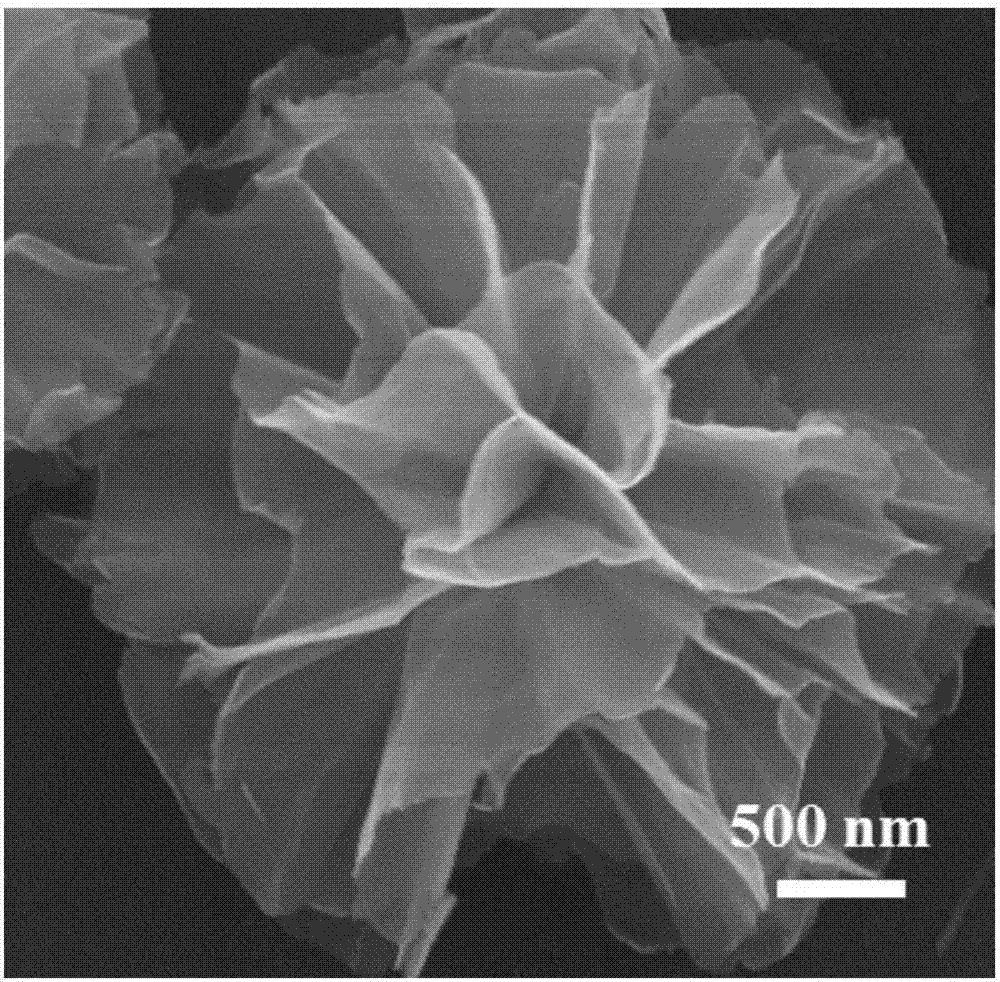

[0067] A variety of characterizations were carried out on the product of this example: using a scanning electron microscope (SEM) and a transmission electron microscope (TEM) to observe the morphology of the porous nickel cobaltate nanosheet / hollow carbon sphere composite material rich in oxygen vacancies, and obtain a micron flower assembled by the nanoshee...

Embodiment 3

[0070] The present invention provides a method for growing porous nickel cobaltate nanosheets rich in oxygen vacancies based on a hollow carbon sphere template, which is basically the same as that in Example 1, except that the heat treatment of the composite is carried out at 5°C under an air atmosphere. Raise the temperature to 260°C at a rate of 1 / min, keep it warm for 2 hours, and then cool to room temperature with the furnace, and the porous nickel cobaltate nanosheet / hollow carbon sphere composite is obtained, named NiCo 2 o 4 / HCS-260.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com