Biological feed for cassava, and preparation method and use thereof

A biological feed and cassava technology, applied in the field of cassava biological feed and its preparation, can solve the problems of no competitive advantage of cassava feed, short storage time of cassava, low utilization rate of cassava, etc., to reduce the odor of animal manure and improve the environment of livestock houses , improve the effect of digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of cassava biological feed, comprises cassava, auxiliary material and probiotic, wherein, the weight ratio of described cassava, auxiliary material and probiotic is, 40:15:1;

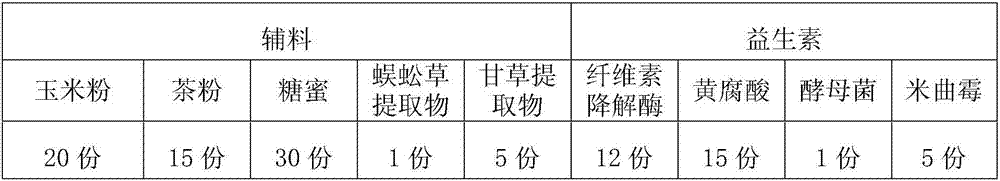

[0024] The present embodiment auxiliary material, probiotics comprise the composition by weight as described in table 1:

[0025] Table 1

[0026]

[0027] In the above example, the tea powder processing method is: take fried black tea and 3 times the mass of rice washing water at a temperature of 90°C, mix and soak for 5 hours, then filter, take the filter residue for drying, and then add 3 times the mass of Formaldehyde solution with a percentage of 30% (v / v), then add sulfuric acid with the same mass ratio as formaldehyde and a mass concentration of 0.01mol / L, mix well, then heat under reflux in a water bath at 60°C, heat for 4 hours, and then filter to take the filter residue for use Wash with water until neutral, then dry, stop washing when the water content is 3%, grind after was...

Embodiment 2

[0035] A kind of cassava biological feed, comprises cassava, auxiliary material and probiotic, wherein, the weight ratio of described cassava, auxiliary material and probiotic is, 50:20:5;

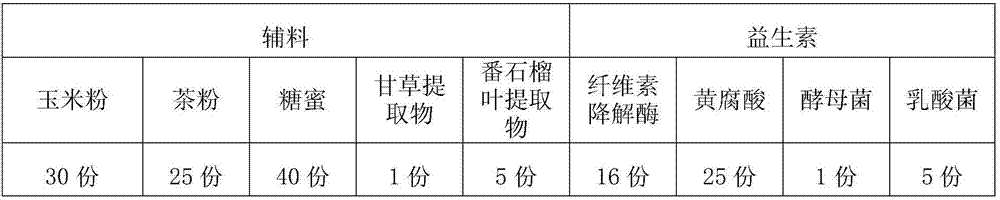

[0036] The present embodiment auxiliary material, probiotics comprise the composition by weight as described in table 2:

[0037] Table 2

[0038]

[0039] In the above example, the tea powder processing method is: take roasted black tea and 5 times the mass of rice washing water at a temperature of 100°C, mix and soak for 8 hours, then filter, take the filter residue for drying, and then add 6 times the mass of Formaldehyde solution with a percentage of 35% (v / v), and then add sulfuric acid with the same mass ratio as formaldehyde and a mass concentration of 0.03mol / L, mix well, then heat under reflux in a water bath at 70°C, heat for 6 hours, and then filter to get the filter residue. Wash with water until neutral, then dry, stop washing when the water content is 5%, grind after wash...

Embodiment 3

[0047] A kind of cassava biological feed, comprises cassava, auxiliary material and probiotic, wherein, the weight ratio of described cassava, auxiliary material and probiotic is, 45:17:2;

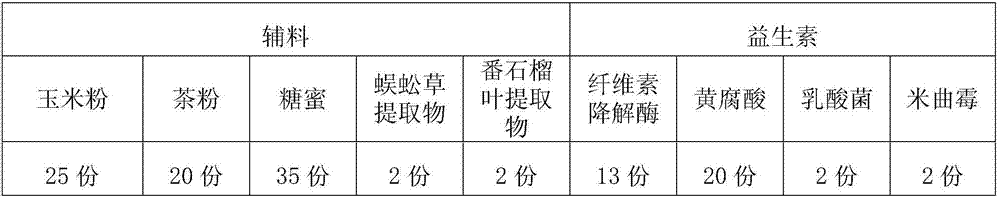

[0048] The present embodiment auxiliary material, probiotics comprise the composition by weight as described in table 3:

[0049] table 3

[0050]

[0051] In the above examples, the tea powder processing method is as follows: take roasted black tea and 4 times the mass of rice washing water at a temperature of 95°C, mix and soak for 4 hours, then filter, take the filter residue for drying, and then add 3-6 times the mass of Formaldehyde solution with a volume percentage of 32% (v / v), and then add sulfuric acid with the same mass ratio as formaldehyde and a mass concentration of 0.02mol / L, mix thoroughly, heat under reflux in a water bath at 65°C, heat for 5 hours, and then filter to take The filter residue is washed with water until it is neutral, and then dried until the water conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com