Antibacterial silk fibroin material and preparation method thereof

A technology of silk fibroin and antibacterial silk, applied in coatings, medical science, absorbent pads, etc., can solve the problems of short release time of antibacterial drugs, instability of silver ions, and inconspicuous antibacterial effect, and achieve the prevention of different tissues Wound infection, wide range of uses, and the effect of promoting tissue healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of antibacterial silk fibroin material is as follows, take by weighing 30g silkworm undegummed silk in 12L boiling Na 2 CO 3 (0.02M) aqueous solution for 30 minutes, then rinse with deionized water, and put the washed silk fibroin fibers in a fume hood to dry naturally overnight. Weigh 25g of dried silk fibroin fiber and dissolve it in 100ml of LiBr (9.3M) solution, and dissolve it in an oven at 60°C for 4 hours, taking it out every hour and shaking slightly to ensure complete dissolution. The solution was taken out and poured into a dialysis bag (MWCO 3500), dialyzed in deionized water for 36 hours, and the water was changed every 4 hours. The dialyzed solution was centrifuged twice at 9000 r / min in a high-speed centrifuge for 20 minutes each time to remove impurities, and finally a silk fibroin solution was obtained, which was placed in a 4°C refrigerator for use. The mass fraction of silk protein solution was determined by evaporation w...

Embodiment 2

[0033] A preparation method of an antibacterial silk fibroin material is as follows, adopt the method in Example 1 to prepare a silk fibroin solution with a concentration of 5-10% (w / v), dissolve berberine in deionized water, and then add silk fibroin Protein solution, the mass ratio of silk fibroin in the berberine and silk fibroin solution is 5 / 100, mix well and pour it into a polystyrene plate, put it into a fume hood and dry it overnight, and then steam it for 5~ 10 hours, the treatment temperature is 50~70 ℃, obtains the antibacterial silk fibroin material through steam treatment.

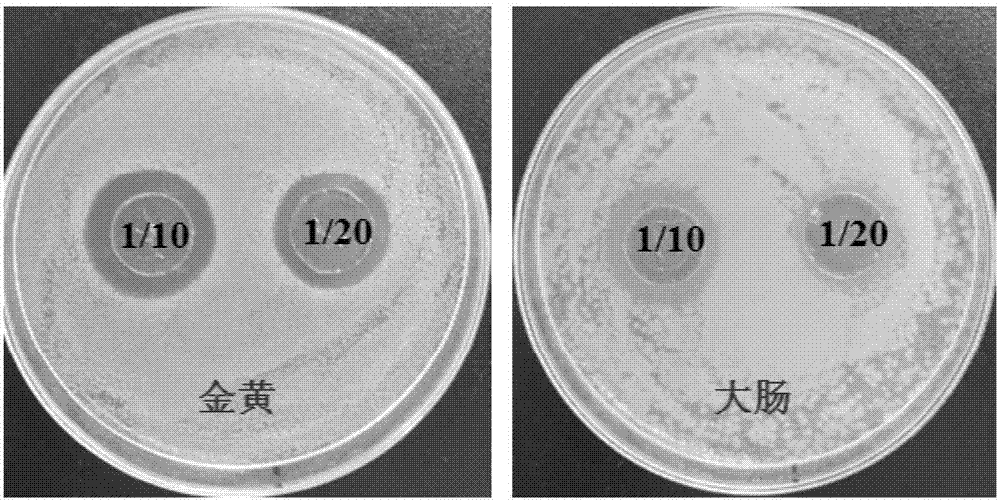

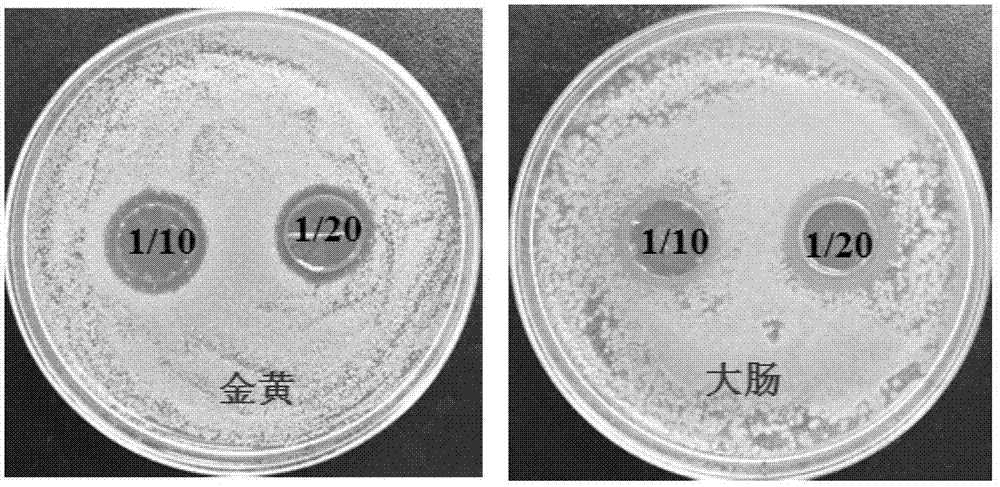

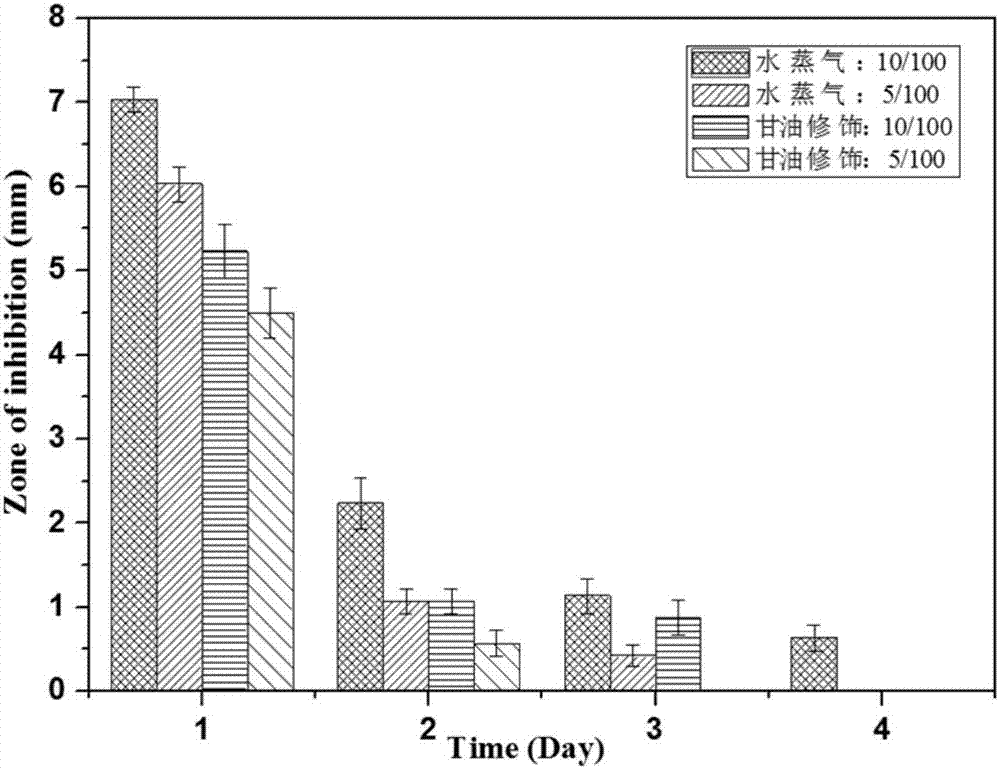

[0034] see figure 1 as shown, figure 1 It is the antibacterial silk fibroin material through water vapor treatment described in embodiment 1 and example 2, according to the antibacterial GB / T20944.1-2007 agar plate diffusion method, to Gram-positive Staphylococcus aureus (S. Diagram of the results of antibacterial experiments carried out on Lambert-negative Escherichia coli (E. coli); among ...

Embodiment 3

[0036] A method for preparing an antibacterial silk fibroin material, using the method in Example 1 to prepare a silk fibroin solution with a concentration of 5-10% (w / v), adding glycerin, glycerin and silk fibroin to the above silk fibroin solution The mass ratio of silk fibroin in the protein solution is 25-35 / 100. After stirring evenly, let it stand for 5-15 minutes, and then add the berberine aqueous solution. The mass ratio of the berberine to the silk fibroin in the silk fibroin solution is 10 / 100, mixed evenly and poured into a polystyrene plate, put into a fume hood and dried overnight to obtain a glycerin-modified antibacterial silk fibroin material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com