Method for producing flaky aluminum powder effect pigment by using non-solvent method

A technology of effect pigments and non-solvent method, which is applied in the direction of fibrous fillers, inorganic pigment treatment, chemical instruments and methods, etc., which can solve the problems of high production cost, low efficiency of ball milling process, unusability, etc., and achieve the effect of not being easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

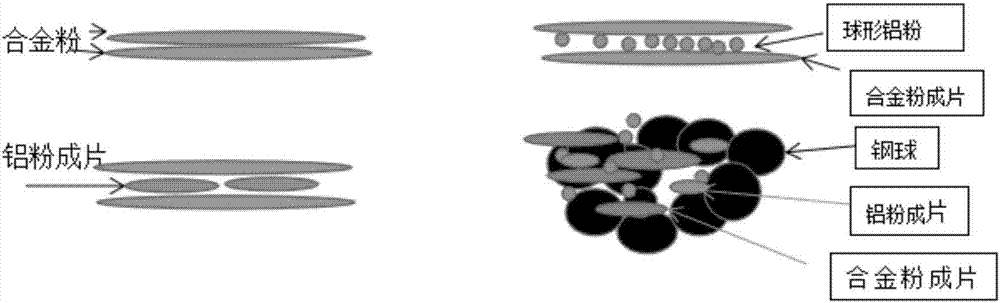

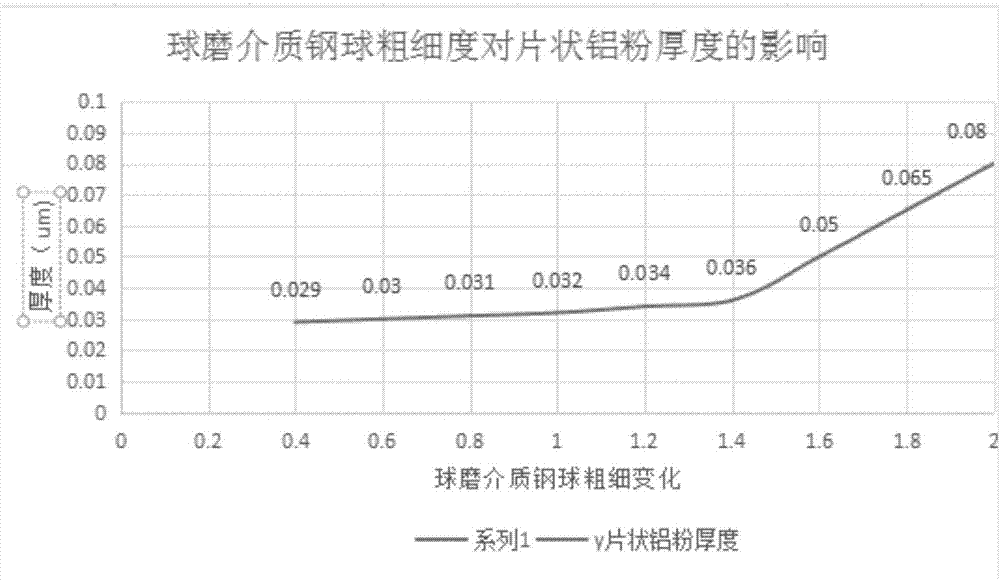

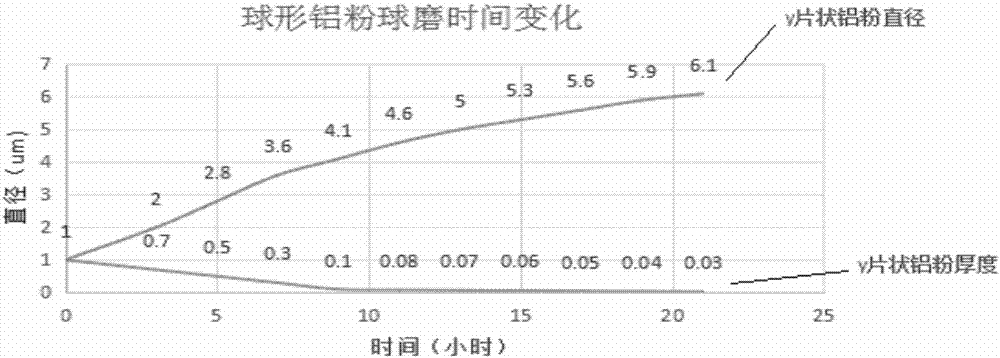

Method used

Image

Examples

Embodiment 1

[0041] Use the average particle size D 50 1.5 μm, D 100 99% spherical aluminum powder as raw material, using steel balls and spherical zinc-aluminum alloy powder with an average particle size of 30μm as the ball milling medium, the aluminum powder is ball milled, the diameter of the ball milling medium stainless steel ball is 0.5mm -1.5mm. Wherein relative to the total weight of the ball milling medium, the weight of the steel ball and the zinc-aluminum alloy powder is shown in Table 1 below; then the flaky aluminum powder after the ball milling is separated, and the polishing medium with a diameter of 200mm, a length of 4000mm, and a filling of 40% is used. Polishing machine is polished to it, and using auxiliary agent is stearic acid, polyvinyl alcohol, polyethylene wax compound auxiliary agent, and stearic acid content is 97wt%, and polyvinyl alcohol, polyethylene wax content are 0.5wt% and 2.5wt% respectively %, the amount of additives used is 5% relative to the mass of ...

Embodiment 2

[0045] Use the average particle size D 50 1.5 μm, D 100 99% spherical aluminum powder as raw material, using steel balls and spherical zinc-aluminum alloy powder with an average particle size of 30μm as the ball milling medium, the aluminum powder is ball milled, the diameter of the ball milling medium stainless steel ball is 0.5mm -1.5mm. Wherein relative to the total weight of the ball milling medium, the steel ball weight is 60%, the weight of the zinc-aluminum alloy powder is 40%, and the mass ratio of the spherical aluminum powder and the ball milling medium (steel ball and zinc-aluminum alloy powder) is as shown in the table below; then separate The flake aluminum powder after ball milling is polished with a polishing machine with a diameter of 200mm, a length of 4000mm, and 40% of the polishing medium filled inside. The additives used are stearic acid, polyvinyl alcohol, and polyethylene wax composite additives. The content of stearic acid is 97wt%, the contents of po...

Embodiment 3

[0048] Use the average particle size D 50 1.5 μm, D 100 Aluminum powder 99% is used as raw material, and steel balls and spherical zinc-aluminum alloy powder with an average particle size of 30μm are used as ball milling media to mill the aluminum powder. The diameter of the ball milling medium stainless steel ball is 0.5mm- 1.5mm. Among them, relative to the total weight of the ball milling medium, the steel ball weight is 60%, the weight of the zinc-aluminum alloy powder is 40%, and the zinc-aluminum content ratio in the zinc-aluminum alloy powder is shown in Table 1 below; powder, use diameter 200mm, length 4000mm, the polishing machine that the inside fills 40% polishing medium to polish it, use auxiliary agent to be stearic acid, polyvinyl alcohol, polyethylene wax composite auxiliary agent, stearic acid content 97wt%, The contents of polyvinyl alcohol and polyethylene wax are 0.5wt% and 2.5wt%, respectively, and the amount of additives used is 5% relative to the mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com