Device and method for producing normal propyl alcohol by utilizing carbon dioxide

A carbon dioxide, n-propanol technology, applied in chemical instruments and methods, ethylene production, preparation of organic compounds, etc., can solve problems such as devices and methods for large-scale production that have not yet been found, avoid air pollution and energy waste, and satisfy Environmental protection requirements, the effect of avoiding water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

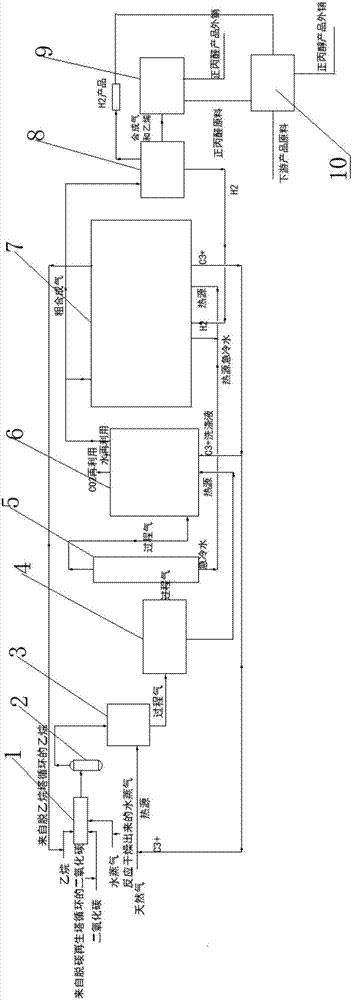

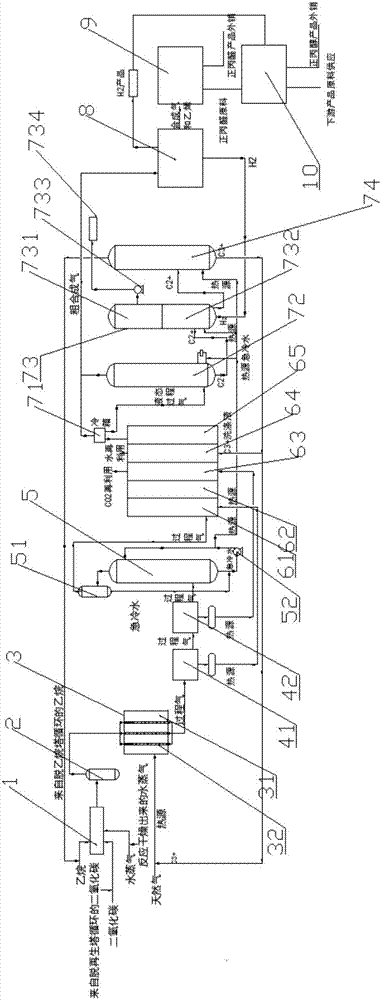

[0041] Please refer to figure 1 , the invention discloses a device for producing n-propanol by utilizing carbon dioxide, which comprises a raw material mixing unit 1, a buffer unit 2, a reaction unit 3, a waste heat recovery unit 4, a rapid cooling unit 5, a compression unit 6, and a separation unit 7 in sequence according to the reaction steps , PSA unit 8, n-propionaldehyde production unit 9 and n-propanol production unit 10;

[0042] see figure 2 As shown, wherein the reaction unit 3 is a reaction furnace 31 with a feed preheater; a reaction furnace tube 32 is arranged in the reaction furnace 31; the reaction furnace 31 is a vertical box furnace;

[0043] The waste heat recovery unit 4 includes a primary waste heat boiler 41 and a secondary waste heat boiler 42;

[0044] The quenching unit 5 is a quenching tower comprising a liquid separator tank 51 at the top of the tower, a quenching water pump 52 at the bottom of the tower and a filter at the bottom of the tower (not ...

Embodiment 2

[0062] The device is the same as in Example 1.

[0063] Based on above-mentioned device, a kind of method utilizing carbon dioxide to produce n-propanol comprises following reaction process:

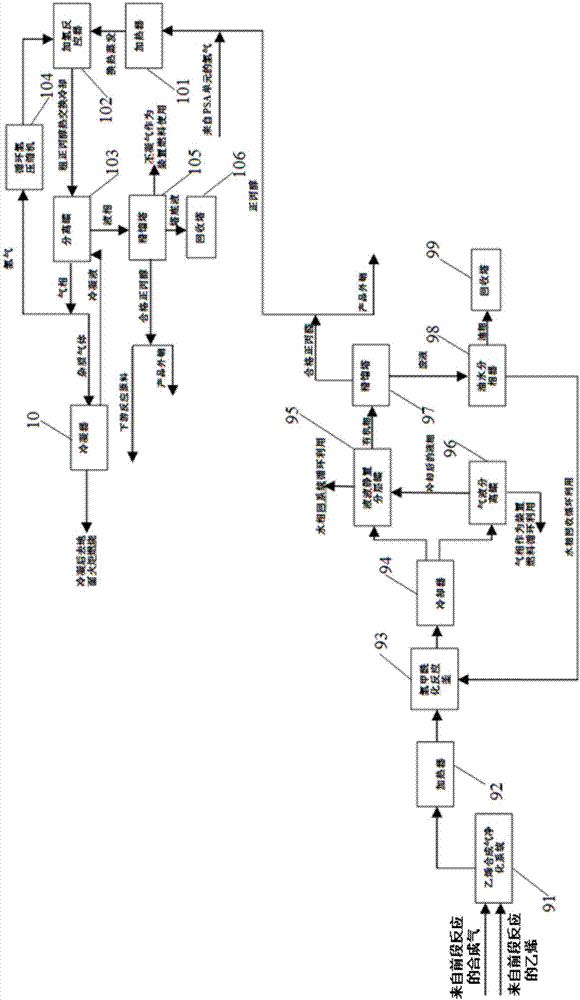

[0064] (1) Raw material mixing unit 1, buffer unit 2 and reaction unit 3: three feeds are mixed in raw material mixing unit 1, the first feed is ethane and recycled ethane, the second feed is carbon dioxide and recycled carbon dioxide , the third feed is water vapor; the three feeds enter the buffer unit 2 after being mixed, and then enter the feed preheater in the reaction unit 3, and enter the reaction furnace 31 after preheating to 100-400 ° C for a temperature rise reaction; The reaction furnace tube 32 is equipped with an ethane dehydrogenation catalyst. When the temperature is raised to 500-1100°C, ethane, carbon dioxide, and water vapor react under the action of the catalyst to generate the main product ethylene; and carbon monoxide, hydrogen, methane, C 3+ Hydrocarbons, water an...

Embodiment 3

[0076] Device is identical with embodiment 1;

[0077] Based on above-mentioned device, a kind of method utilizing carbon dioxide to produce n-propanol comprises following reaction process:

[0078] (1) Raw material mixing unit 1, buffer unit 2 and reaction unit 3: three feeds are mixed in raw material mixing unit 1, the first feed is ethane and recycled ethane, the second feed is carbon dioxide and recycled carbon dioxide , the third feed is water vapor; the three feeds enter the buffer unit 2 after mixing, and then enter the feed preheater in the reaction unit 3, and enter the reaction furnace 31 after preheating to 220 ° C for heating reaction; the reaction furnace The tube 32 is equipped with an ethane dehydrogenation catalyst. When the temperature is raised to 1000°C, ethane, carbon dioxide, and water vapor react under the action of the catalyst to produce ethylene as the main product; and carbon monoxide, hydrogen, methane, C 3+ Hydrocarbons, water and other by-products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com