Nanocellulose compound temperature-sensitive type hydrogel and preparation method thereof

A nano-cellulose and temperature-sensitive technology, which is applied in the field of nano-cellulose composite temperature-sensitive hydrogel and its preparation, can solve the problems of uneven crosslink density, poor toughness, and low mechanical strength of the gel, and achieve Improved elasticity and gel strength and rupture strength, good biocompatibility, increased stiffness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

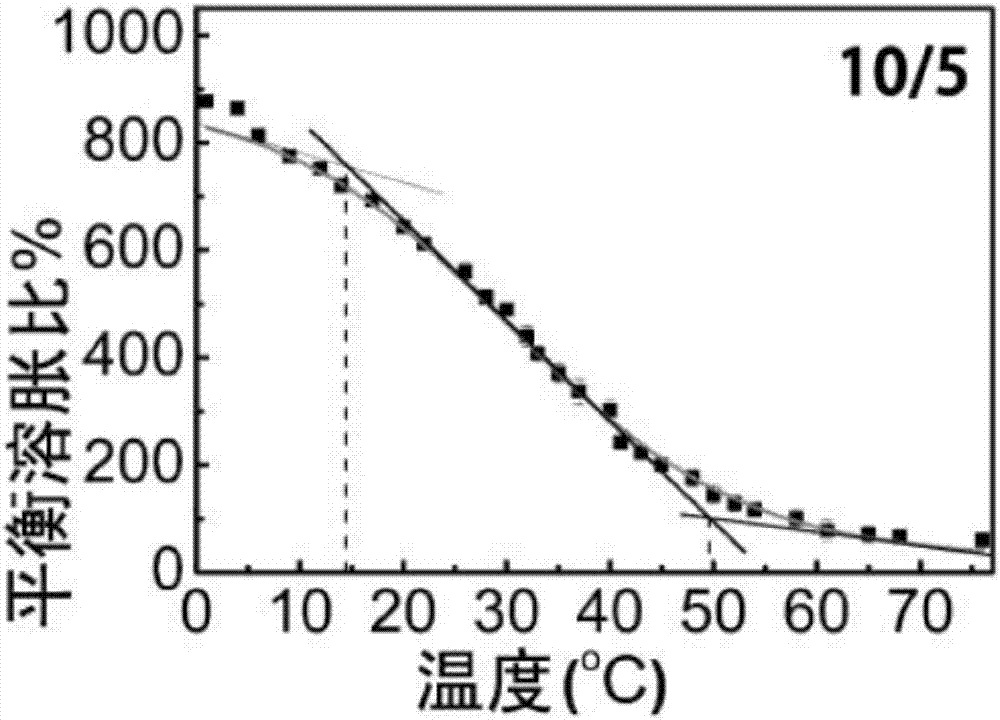

Embodiment 1

[0030] An embodiment of the nanocellulose composite temperature-sensitive hydrogel and a preparation method thereof of the present invention. The preparation method of the nanocellulose composite temperature-sensitive hydrogel comprises the following steps:

[0031] Step 1: Take 5g of lignocellulose that has been de-lignified, add 100g of concentrated sulfuric acid with a mass fraction of 48%, and hydrolyze it in a water bath at 45°C for 2 hours, while stirring with a mechanical stirring paddle at 200rpm. After the hydrolysis, add a large amount of ultra-pure Water terminates the reaction to obtain a sulfuric acid-modified cellulose mixed solution.

[0032] Step 2: Place the cellulose mixed solution modified by sulfuric acid in a high-speed centrifuge for 5 minutes, the speed of the centrifuge is 8000rpm, remove the supernatant after centrifugation, and repeatedly wash the centrifuged precipitate with ultrapure water to The pH of the supernatant was 6.5, and the cellulose pre...

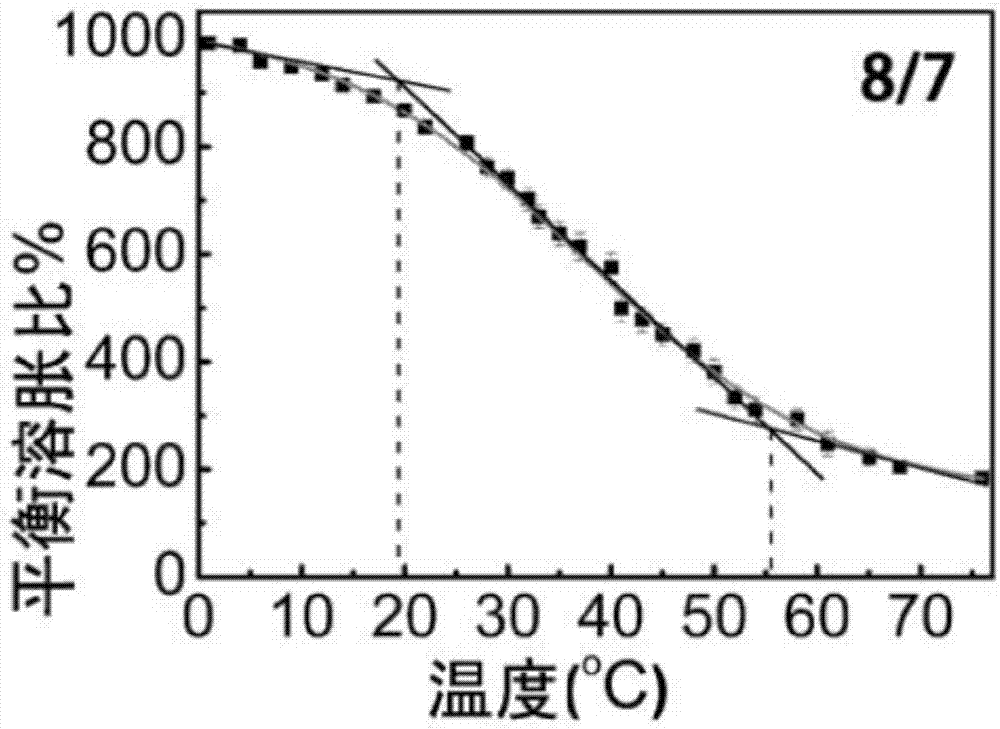

Embodiment 2

[0037] An embodiment of the nanocellulose composite temperature-sensitive hydrogel and a preparation method thereof of the present invention. The preparation method of the nanocellulose composite temperature-sensitive hydrogel comprises the following steps:

[0038]Step 1: Take 5g of lignocellulose that has been de-lignified, add 100g of concentrated sulfuric acid with a mass fraction of 48%, and hydrolyze it in a water bath at 45°C for 2 hours, while stirring with a mechanical stirring paddle at 200rpm. After the hydrolysis, add a large amount of ultra-pure Water terminates the reaction to obtain a sulfuric acid-modified cellulose mixed solution.

[0039] Step 2: Place the cellulose mixed solution modified by sulfuric acid in a high-speed centrifuge for 5 minutes, the speed of the centrifuge is 8000rpm, remove the supernatant after centrifugation, and repeatedly wash the centrifuged precipitate with ultrapure water to The pH of the supernatant was 6.5, and the cellulose prec...

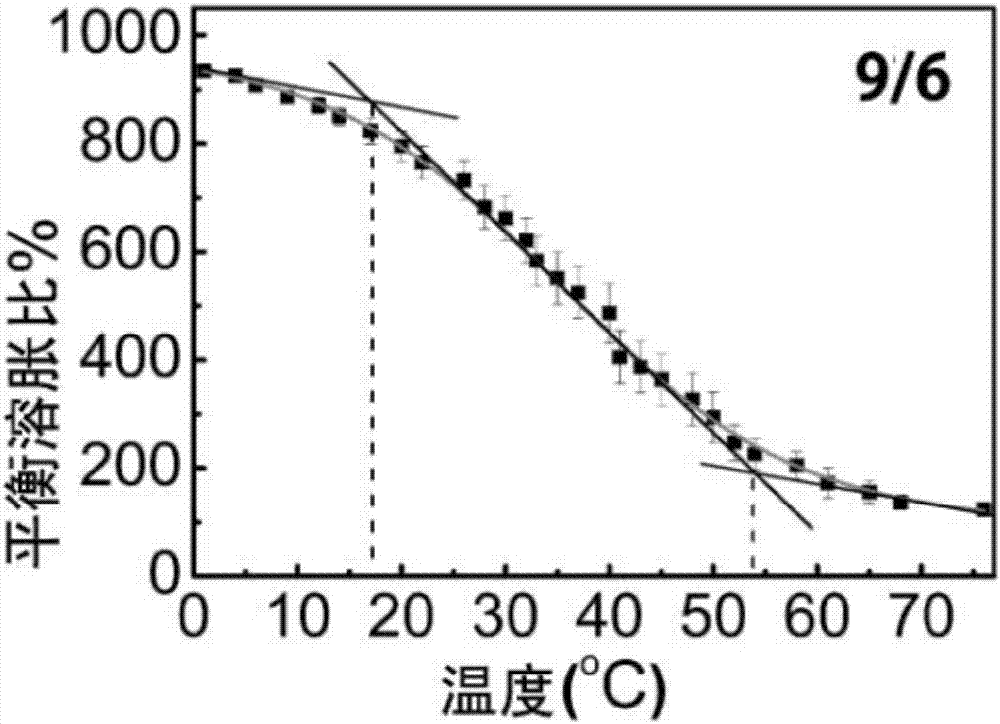

Embodiment 3

[0044] An embodiment of the nanocellulose composite temperature-sensitive hydrogel and a preparation method thereof of the present invention. The preparation method of the nanocellulose composite temperature-sensitive hydrogel comprises the following steps:

[0045] Step 1: Take 5g of lignocellulose that has been de-lignified, add 100g of concentrated sulfuric acid with a mass fraction of 48%, and hydrolyze it in a water bath at 45°C for 2 hours, while stirring with a mechanical stirring paddle at 200rpm. After the hydrolysis, add a large amount of ultra-pure Water terminates the reaction to obtain a sulfuric acid-modified cellulose mixed solution.

[0046] Step 2: Place the cellulose mixed solution modified by sulfuric acid in a high-speed centrifuge for 5 minutes, the speed of the centrifuge is 8000rpm, remove the supernatant after centrifugation, and repeatedly wash the centrifuged precipitate with ultrapure water to The pH of the supernatant was 6.5, and the cellulose pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com