Water shutoff agent and preparation method thereof

A technology of water blocking agent and reinforcing agent, applied in the field of water blocking agent and its preparation, can solve the problems of high temperature resistance, poor salinity resistance performance of water blocking agent, clogging of water blocking agent, etc., so as to improve the salinity resistance. performance, improve high temperature resistance, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

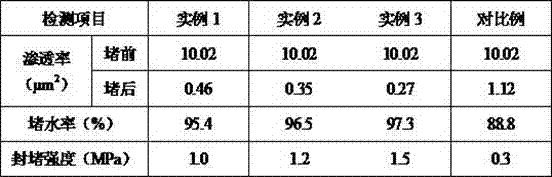

Examples

example 1

[0023] Take 20g of graphene powder, 10g of sodium periodate and 100mL of nitric acid solution with a mass fraction of 65% into a beaker, move the beaker into a water bath, control the temperature of the water bath to 85°C, stir and react for 60 minutes and then filter to obtain a filter residue. Wash 3 times with water to obtain a cleaned filter residue, add the cleaned filter residue, 100g of Sphagnum tenifolia and 80mL of water to a mortar and grind for 15min to obtain a mixed slurry, mix the mixed slurry, 10g of glucose, 3g of ammonium tartrate and 600mL of water Add it into the fermenter, and ferment it at 30°C for 5 days. After the fermentation, the fermentation product is obtained, and the fermentation product is moved into an oven, and dried at 120°C for 5 hours to obtain a dry product, which is mixed with 80 mL of methallyl alcohol Add it into a three-necked flask with a thermometer and a reflux device, move the three-necked flask into an oil bath, control the temperatu...

example 2

[0025]Take 25g of graphene powder, 11g of sodium periodate and 150mL of nitric acid solution with a mass fraction of 65% into a beaker, move the beaker into a water bath, control the temperature of the water bath to 90°C, stir and react for 75 minutes and then filter to obtain a filter residue. Wash 4 times with water to obtain a clean filter residue, add the clean filter residue, 150g sphagnum moss and 90mL water to a mortar and grind for 18min to obtain a mixed slurry, mix the slurry, 13g glucose, 4g ammonium tartrate and 700mL water Add it into a fermenter and ferment in a sealed container at 35°C for 5 days. After the fermentation is over, the fermentation product is obtained. The fermentation product is moved into an oven and dried at 125°C for 5 hours to obtain a dried product. The dried product is mixed with 90 mL of methallyl alcohol Add it into a three-necked flask with a thermometer and a reflux device, move the three-necked flask into an oil bath, control the tempera...

example 3

[0027] Take 30g of graphene powder, 12g of sodium periodate and 200mL of nitric acid solution with a mass fraction of 65% into a beaker, move the beaker into a water bath, control the temperature of the water bath to 95°C, stir and react for 90 minutes and then filter to obtain a filter residue. Wash 5 times with water to obtain a cleaned filter residue, add the cleaned filter residue, 200g of Sphagnum tenifolia and 100mL of water to a mortar and grind for 20min to obtain a mixed slurry, mix the mixed slurry, 15g of glucose, 5g of ammonium tartrate and 800mL of water Add it into the fermenter, and ferment in a sealed manner at 40°C for 6 days. After the fermentation is over, the fermentation product is obtained, and the fermentation product is moved into an oven, and dried at 130°C for 6 hours to obtain a dry product, which is mixed with 100 mL of methallyl alcohol Add it into a three-necked flask with a thermometer and a reflux device, move the three-necked flask into an oil b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com