A method for preparing quasicrystalline porous materials by adding pore-forming agent

A technology of porous materials and pore-forming agents, applied in the field of preparation of high-porosity quasi-crystalline porous materials, can solve problems such as complex methods, harsh conditions, and unsuitability for mass production, and achieve simple process, low cost, and controllable preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Use commercial Al powder, Cu powder, Fe powder, according to the alloy atomic ratio Al 63 Cu 25 Fe 12 Carry out alloy batching, and then mix with a mixer for 4-10h;

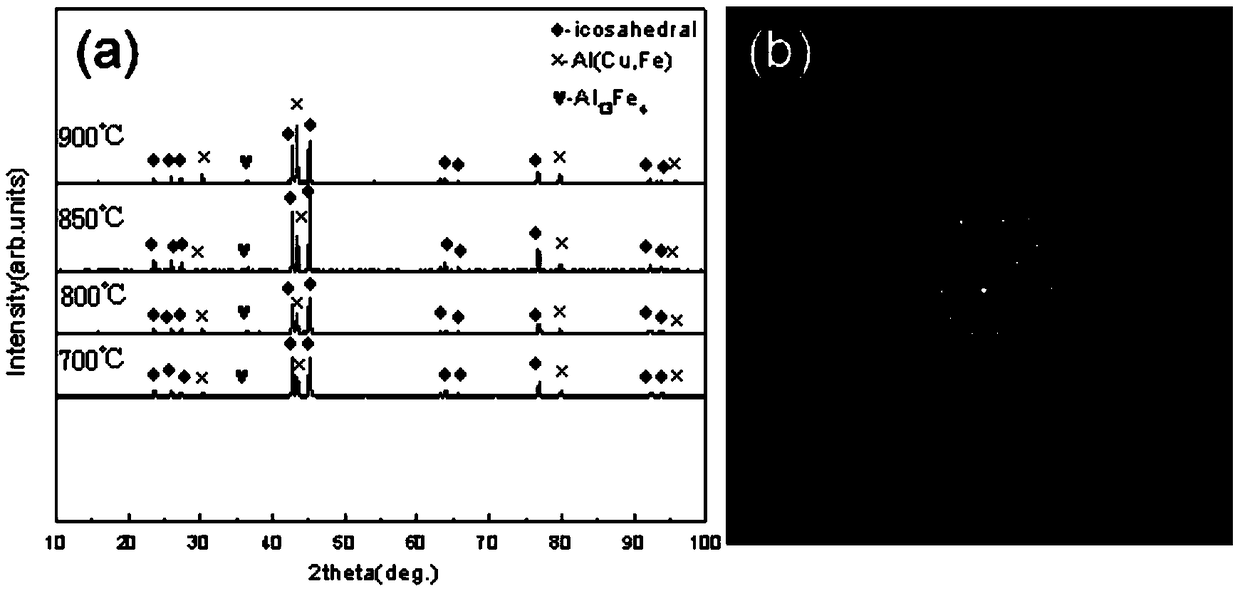

[0020] (2) In the homogeneously mixed Al, Cu, Fe element powders, add ammonium bicarbonate pore-forming agent, the pore-forming agent content accounts for 40wt% of the mass fraction of the mixed material, after mixing uniformly, it is formed into a cylindrical green body by cold pressing for subsequent use, Then put it in a high-temperature atmosphere sintering furnace and sinter at normal pressure under the protection of argon atmosphere; the sintering process is: rise from room temperature to 200-300°C at 5-10°C / min, keep it for 1-2h to remove moisture and pore-forming agent , then rise to 600-650°C at 3-5°C / min, hold for 1-2 hours to make Al react in solid phase, and finally rise to 700-900°C at 2-3°C / min, hold for 2-3 hours, and then The furnace was cooled to room temperature to obtain the quasi...

Embodiment 2

[0023] (1) Use commercial Al powder, Cu powder, Fe powder, according to the alloy atomic ratio Al 63 Cu 25 Fe 12 Carry out alloy batching, and then mix with a mixer for 4-10h;

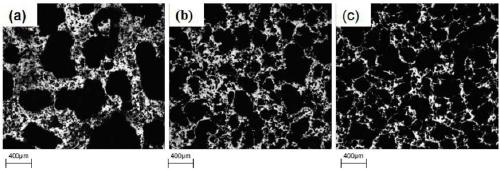

[0024] (2) In the homogeneously mixed Al, Cu, Fe element powder, add ammonium bicarbonate pore forming agent, the content of ammonium bicarbonate pore forming agent accounts for 40wt% of the mass fraction of the mixed powder, and the particle size is -20+40 mesh, -40 +60 mesh, -60 mesh, after mixing evenly, it is cold-pressed and formed into a cylindrical green body for later use, and then placed in a high-temperature atmosphere sintering furnace and sintered under normal pressure under the protection of an argon atmosphere; the sintering process is: 5-10°C / min Raise from room temperature to 250°C, keep it warm for 1 hour to remove moisture and pore-forming agent, then raise it to 600°C at 3-5°C / min, keep it warm for 2 hours to make Al react in solid phase, and finally raise it at 2-3°C / min to 850°C...

Embodiment 3

[0027] (1) Use commercial Al powder, Cu powder, Fe powder, according to the alloy atomic ratio Al 63 Cu 25 Fe 12 Carry out alloy batching, and then mix with a mixer for 4-10h;

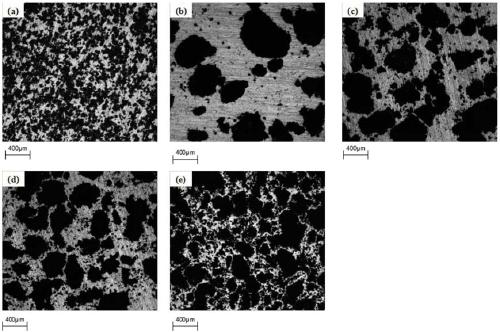

[0028] (2) In the homogeneously mixed Al, Cu, Fe element powder, add ammonium bicarbonate pore-forming agent, the content of ammonium bicarbonate pore-forming agent accounts for 10~40wt% of mixed powder mass fraction, particle size is-40+60 order, After mixing evenly, it is cold-pressed into a cylindrical green body for later use, and then placed in a high-temperature atmosphere sintering furnace and sintered under normal pressure under the protection of an argon atmosphere; Insulate for 1 hour to remove moisture and pore-forming agent, then heat up to 600°C at 3-5°C / min, hold for 2 hours to allow Al to react in solid phase, and finally rise to 850°C at 2-3°C / min, hold for 2 hours, and then Cool to room temperature with the furnace to obtain quasicrystalline porous materials;

[0029] (3) Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com