Cleaning dedusting agent and die-cast zinc alloy pretreatment method

A dust remover and zinc alloy technology, applied in the field of die-casting zinc alloy surface treatment, can solve problems such as difficult to clean, difficult to deal with yellow, endangering the health of operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

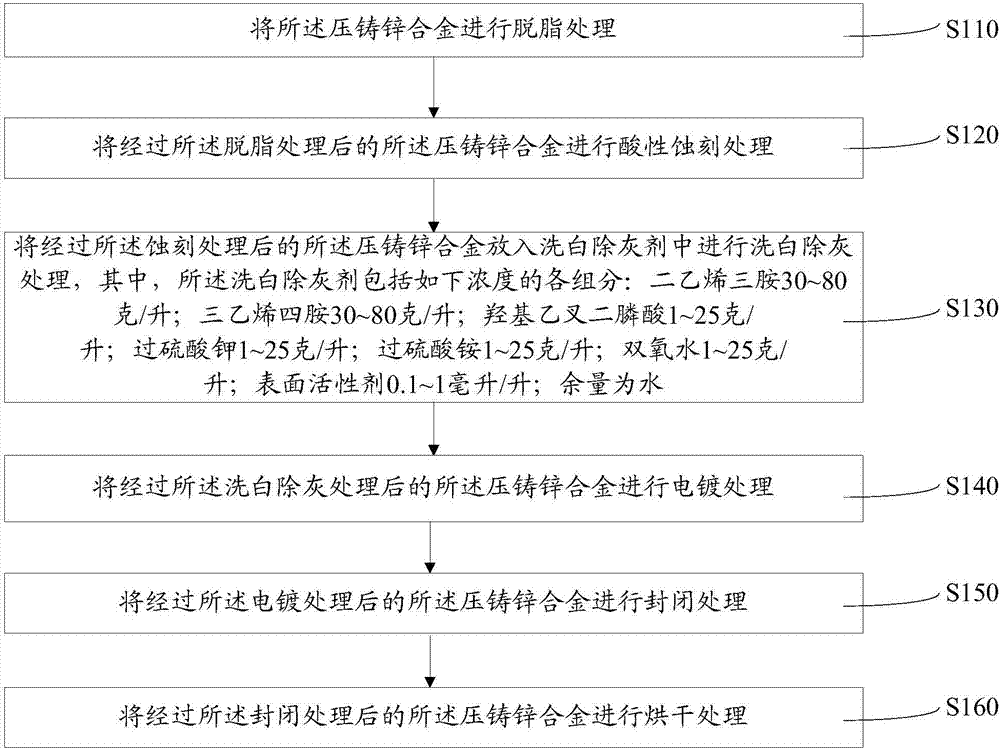

Method used

Image

Examples

Embodiment 1

[0057] 1. Degreasing: use sodium carbonate 10 g / L, sodium tripolyphosphate 20 g / L, sodium tetraborate 5 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees , processed for 6 minutes. After washing with water, put it into the pickling solution below;

[0058] 2. Pickling: use 10ml of sulfuric acid, 10ml / liter of hydrofluoric acid, 0.2ml / liter of low-foaming surfactant, and treat at room temperature for 5-10 seconds. After washing with water, put it into the following treatment solution for processing;

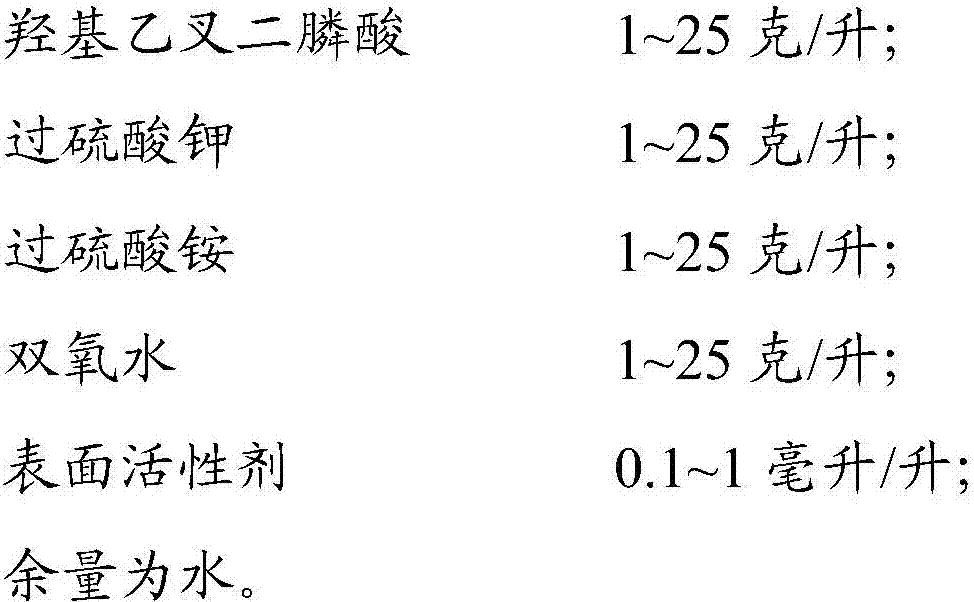

[0059] 3. Whitening: diethylenetriamine 30-80 g / L; triethylenetetramine 30-80 g / L; hydroxyethylidene diphosphonic acid (HEDP) 1-25 g / L; potassium persulfate 1-25 g 1-25 g / L ammonium persulfate; 1-25 g / L 50% hydrogen peroxide; 0.1-1 ml / L surfactant; the balance is water. The temperature is 20-30 degrees, and the time is 5 minutes.

[0060] 4. Trivalent chromization or electroplating: put the above-mentioned treated die-cast zinc alloy workpiece into ...

Embodiment 2

[0064] 1. Degreasing: use sodium carbonate 10 g / L, sodium tripolyphosphate 20 g / L, sodium tetraborate 5 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees , processed for 6 minutes. After washing with water, put it into the pickling solution below;

[0065] 2. Pickling: use 10ml of sulfuric acid, 10ml / liter of hydrofluoric acid, 0.2ml / liter of low-foaming surfactant, and treat at room temperature for 5-10 seconds. After washing with water, put it into the following treatment solution for processing;

[0066] 3. Whitening: diethylenetriamine 30-50 g / L; triethylenetetramine 30-50 g / L; hydroxyethylidene diphosphonic acid (HEDP) 1-25 g / L; potassium persulfate 1-25 g 1-25 grams / liter of ammonium persulfate; 1-25 grams / liter of 50% hydrogen peroxide; 0.1-1 milliliter / liter of surfactant, and the balance is water. The temperature is 20-30 degrees, and the time is 5 minutes. 4. Trivalent chromization or electroplating: put the above-mentioned treated die...

Embodiment 3

[0070] 1. Degreasing: use sodium carbonate 10 g / L, sodium tripolyphosphate 20 g / L, sodium tetraborate 5 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees , processed for 6 minutes. After washing with water, put it into the pickling solution below;

[0071] 2. Pickling: use 10ml of sulfuric acid, 10ml / liter of hydrofluoric acid, 0.2ml / liter of low-foaming surfactant, and treat at room temperature for 5-10 seconds. After washing with water, put it into the following treatment solution for processing;

[0072] 3. Whitening: Diethylene triamine 30 g / L; Triethylene tetramine 50 g / L; Hydroxyethylidene diphosphonic acid (HEDP) 6 g / L; Potassium persulfate 1 g / L; Ammonium persulfate 1 g / liter; 50% hydrogen peroxide 20 grams / liter; surfactant 0.1 ~ 1 ml / liter, the balance is water. The temperature is 20-30 degrees, and the time is 5 minutes.

[0073] 4. Trivalent chromization or electroplating: put the above-mentioned treated die-cast zinc alloy wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com