Preparation method of copper nanowires uniform in shape

A copper nanowire and uniform technology, applied in the field of nanomaterials, can solve the problems of uneven copper nanowire shape, harsh experimental requirements, and difficult operation, and achieve the effect of low raw material cost, easy operation, and low technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

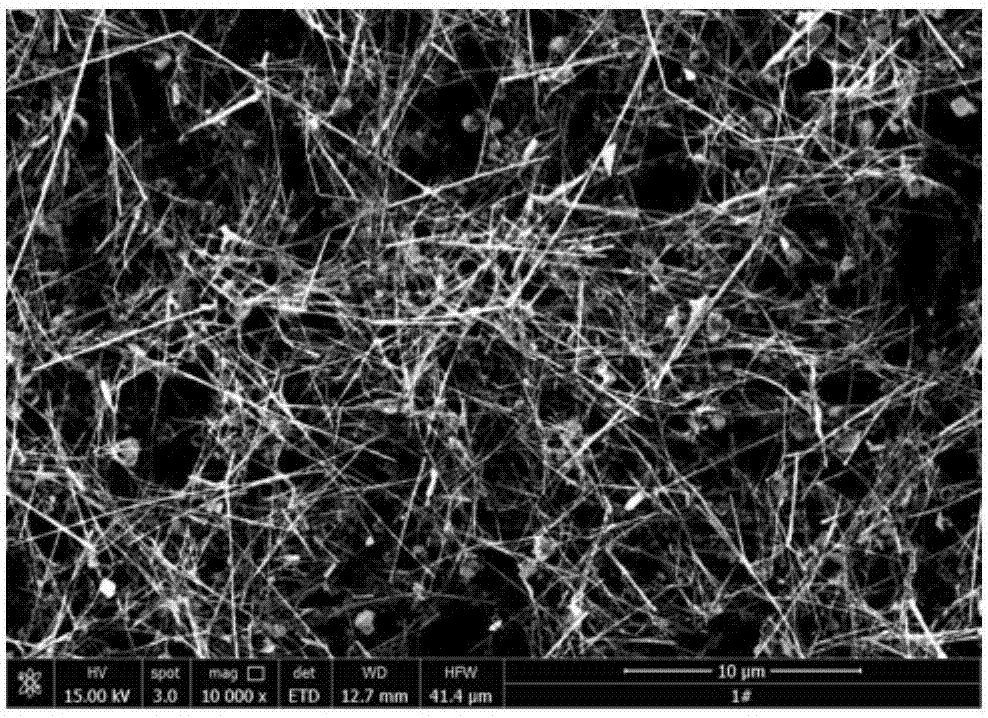

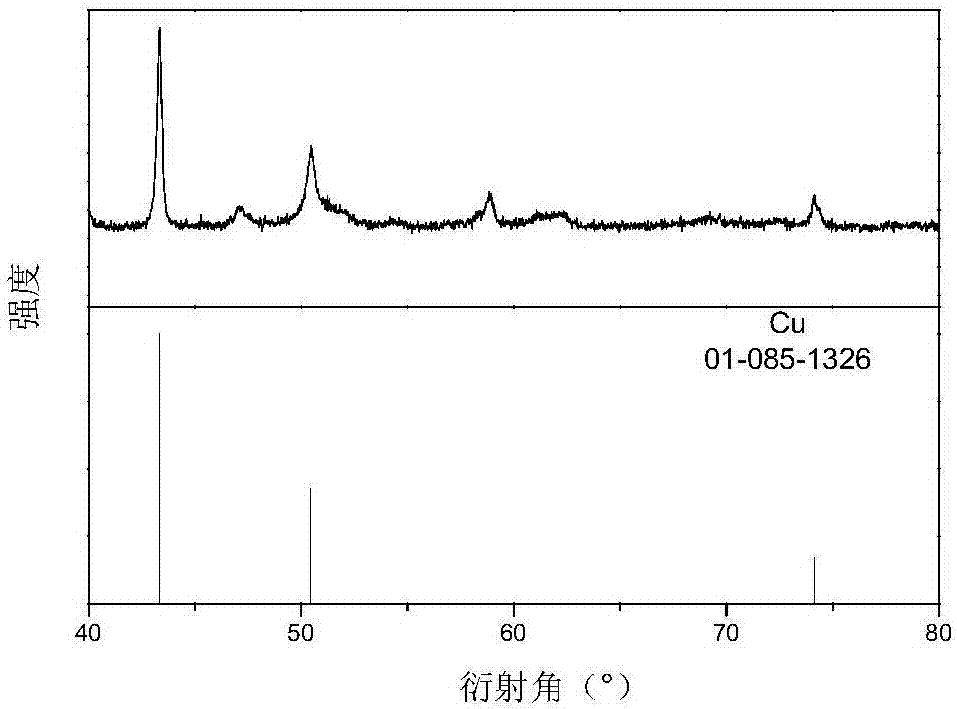

Embodiment 1

[0018] (1) Take 0.1368g (0.8mol) of copper chloride dihydrate and place it in a polytetrafluoroethylene reactor liner with a volume of 15mL, add 0.1027g (0.4mol) of nickel acetylacetonate, then add 10mL of oleylamine, and add A certain amount of nitrogen gas is introduced to remove the air in the inner tank, the reaction kettle is covered and placed in an oven. The parameters of the oven are set as follows: the reaction temperature is 170° C., and the reaction time is 8 hours.

[0019] (2) After the reaction in step (1) is complete, let the reactor cool naturally in an oven to 25°C-40°C, take out the resultant and centrifuge it at 10,000 rad / min for 10 minutes, take the precipitate and pour it into an appropriate amount of n-hexane and then sonicate it , centrifuged again, repeated centrifugation and ultrasonic treatment 3 times, took the precipitate and stored it in a certain amount of n-hexane.

[0020] (3) Centrifuge the precipitate stored in n-hexane in step (2), and dry ...

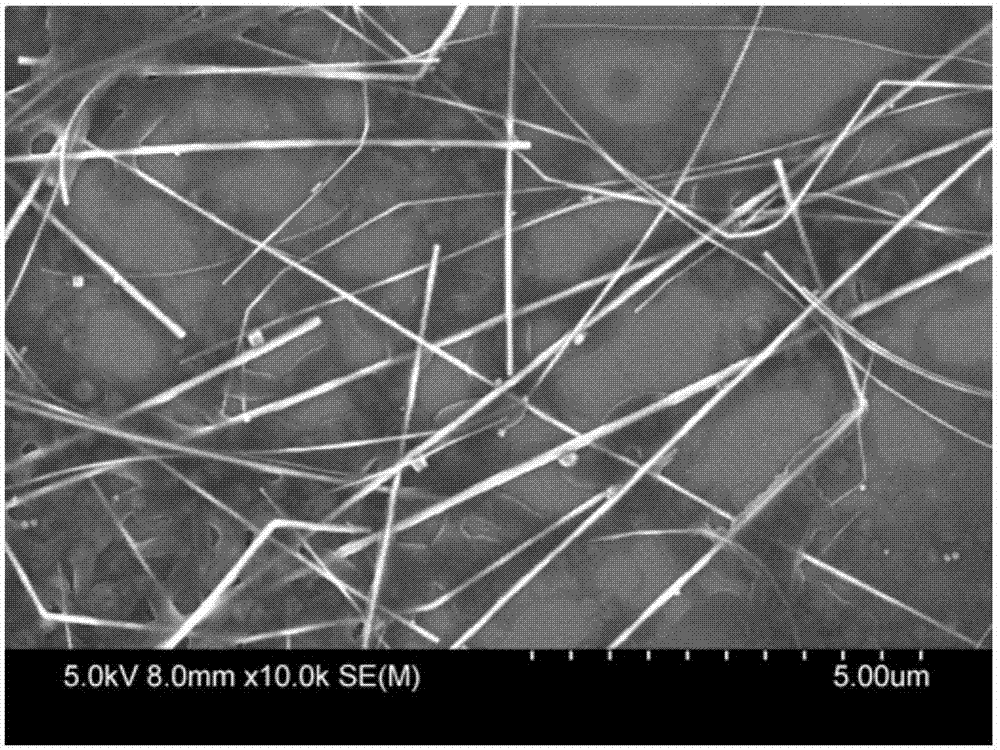

Embodiment 2

[0024] Same as Example 1, the difference is that the reaction temperature in step (1) is changed from 170°C to 175°C, the reaction time is changed from 8 hours to 10 hours, and other conditions remain the same.

Embodiment 3

[0026] Same as in Example 1, the difference is that the reactants in step (1) copper chloride dihydrate and nickel acetylacetonate double in mass at the same time, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com