Refining device of propylene epoxide

A technology of propylene oxide and refining equipment, which is applied in the direction of organic chemistry, can solve the problems of high loss rate of extraction agent and low recovery rate of propylene oxide, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

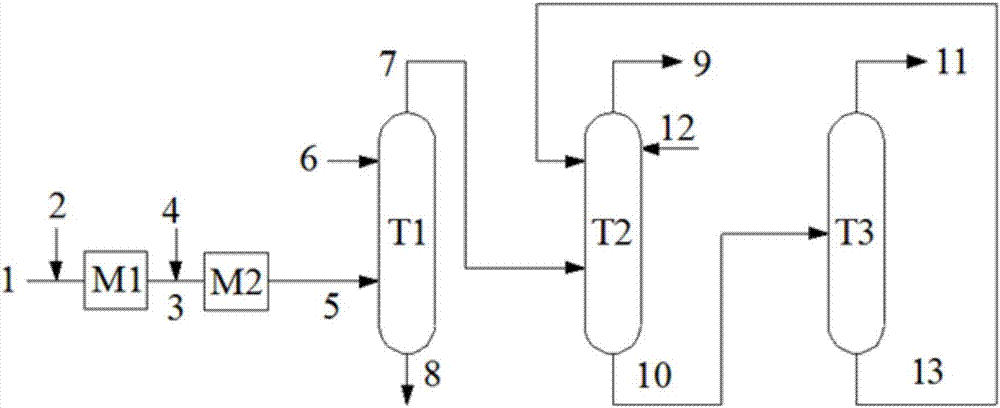

[0033] use figure 1 The device shown contains water, methanol, acetaldehyde, propionaldehyde, acetone, methyl formate, C 5 -C 6 The crude propylene oxide (stream 1) composition of hydrocarbon impurities is shown in Table 1.

[0034] Table 1

[0035] composition

[0036] The flow rate of stream 1 is 10000kg / h, reacts with stream 2 sodium hydroxide solution in the first mixer M1, methyl formate undergoes saponification reaction to generate methyl alcohol and sodium formate, after the reaction, the solution reacts with stream 3 hydrazine solution in the second mixer M2, Carbonyl compounds such as acetaldehyde, propionaldehyde, and acetone are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The number of theoretical plates in the T1 column is 80, the feed position of logistics 6 is the 40th plate, the feed position of the first extraction agent deionized water is the 20th plate, the opera...

Embodiment 2

[0042] use figure 1 The device shown contains water, methanol, acetaldehyde, propionaldehyde, acetone, methyl formate, C 5 -C 6 The composition of the crude propylene oxide solution (stream 1) of impurities such as hydrocarbons is shown in Table 3.

[0043] table 3

[0044] composition

[0045] The flow rate of stream 1 is 10000kg / h, reacts with stream 2 sodium hydroxide solution in the first mixer M1, methyl formate undergoes saponification reaction to generate methyl alcohol and sodium formate, after the reaction, the solution reacts with stream 3 hydrazine solution in the second mixer M2, Carbonyl compounds such as acetaldehyde, propionaldehyde, and acetone are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The theoretical plate number of T1 tower is 60, the feeding position of stream 6 is the 30th plate, the feeding position of the first extraction agent deionized water is the 15...

Embodiment 3

[0051] use figure 1 The device shown contains water, methanol, acetaldehyde, propionaldehyde, acetone, methyl formate, C 5 -C 6 The composition of the crude propylene oxide solution (stream 1) of impurities such as hydrocarbons is shown in Table 5.

[0052] table 5

[0053] composition

[0054] The flow rate of stream 1 is 10000kg / h, reacts with stream 2 sodium hydroxide solution in the first mixer M1, methyl formate undergoes saponification reaction to produce methyl alcohol and sodium formate, after the reaction, the solution reacts with stream 3 hydrazine solution in the second mixer M2, Carbonyl compounds such as acetaldehyde, propionaldehyde, and acetone are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The number of theoretical plates in the T1 column is 70, the feed position of stream 6 is the 32nd plate, the feed position of the first extraction agent deionized water / de-salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com