Ageing-resistant sealing material for chemical pump

A sealing material and anti-aging technology, applied in the field of chemical pump preparation, can solve the problems of performance deterioration, cross-linking, fracture, etc., and achieve the effect of improving anti-aging performance, improving incision and tearing resistance, and avoiding chain breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

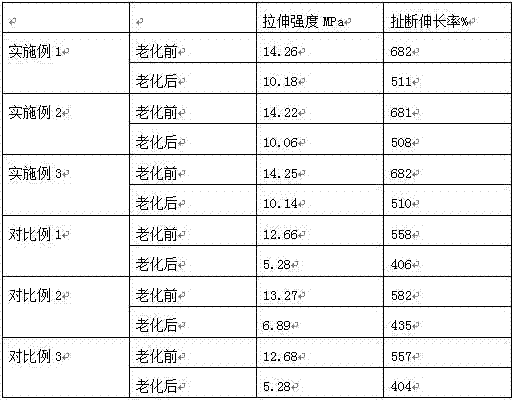

Examples

Embodiment 1

[0013] An aging-resistant sealing material for chemical pumps, the rubber sealing material is made of the following components in parts by mass: 82 parts of hydrogenated nitrile rubber, 12 parts of wood powder / high-density polyethylene composite material, silane coupling agent 1.4 parts, 2.6 parts of diacetyl peroxide, 3 parts of polybutene, 5 parts of diatomaceous earth, 4 parts of white carbon black, 0.3 parts of polyethylene glycol, 1 part of sulfur;

[0014] The preparation method of the wood flour / high-density polyethylene composite material is as follows: 750 mesh wood flour is soaked in a succinic acid solution with a mass fraction of 3.8% for 2.5 hours, and then filtered, and the mass fraction is 5% in a sodium bicarbonate solution. Soak in water for 30 minutes, filter, soak in clean water for 10 minutes, and dry to constant weight. Add high-density polyethylene, dried wood powder, and maleic anhydride to a high-speed mixer at a mass ratio of 18:1.5:0.2. After mixing, ...

Embodiment 2

[0020] An aging-resistant sealing material for chemical pumps, the rubber sealing material is made of the following components in parts by mass: 88 parts of hydrogenated nitrile rubber, 16 parts of wood powder / high-density polyethylene composite material, silane coupling agent 1.8 parts, 3.0 parts of diacetyl peroxide, 5 parts of polybutene, 8 parts of diatomaceous earth, 6 parts of white carbon black, 0.6 parts of polyethylene glycol, 3 parts of sulfur;

[0021] The preparation method of the wood flour / high-density polyethylene composite material is as follows: 750 mesh wood flour is soaked in a succinic acid solution with a mass fraction of 3.8% for 2.5 hours, and then filtered, and the mass fraction is 5% in a sodium bicarbonate solution. Soak in water for 30 minutes, filter, soak in clean water for 10 minutes, and dry to constant weight. Add high-density polyethylene, dried wood powder, and maleic anhydride to a high-speed mixer at a mass ratio of 18:1.5:0.2. After mixing,...

Embodiment 3

[0027] An aging-resistant sealing material for chemical pumps, the rubber sealing material is made of the following components in parts by mass: 86 parts of hydrogenated nitrile rubber, 14 parts of wood powder / high-density polyethylene composite material, silane coupling agent 1.5 parts, 2.8 parts of diacetyl peroxide, 4 parts of polybutene, 7 parts of diatomaceous earth, 5 parts of white carbon black, 0.4 parts of polyethylene glycol, 2 parts of sulfur;

[0028] The preparation method of the wood flour / high-density polyethylene composite material is as follows: 750 mesh wood flour is soaked in a succinic acid solution with a mass fraction of 3.8% for 2.5 hours, and then filtered, and the mass fraction is 5% in a sodium bicarbonate solution. Soak in water for 30 minutes, filter, soak in clean water for 10 minutes, and dry to constant weight. Add high-density polyethylene, dried wood powder, and maleic anhydride to a high-speed mixer at a mass ratio of 18:1.5:0.2. After mixing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com