Manufacturing method of polyimide with low dielectric coefficient, polyimide film and application thereof

A polyimide film, polyimide technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of poor tensile strength and elongation, unfavorable development of high-frequency substrates, Tear resistance, bending resistance, transparency and dimensional stability are not good, to achieve the effect of good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

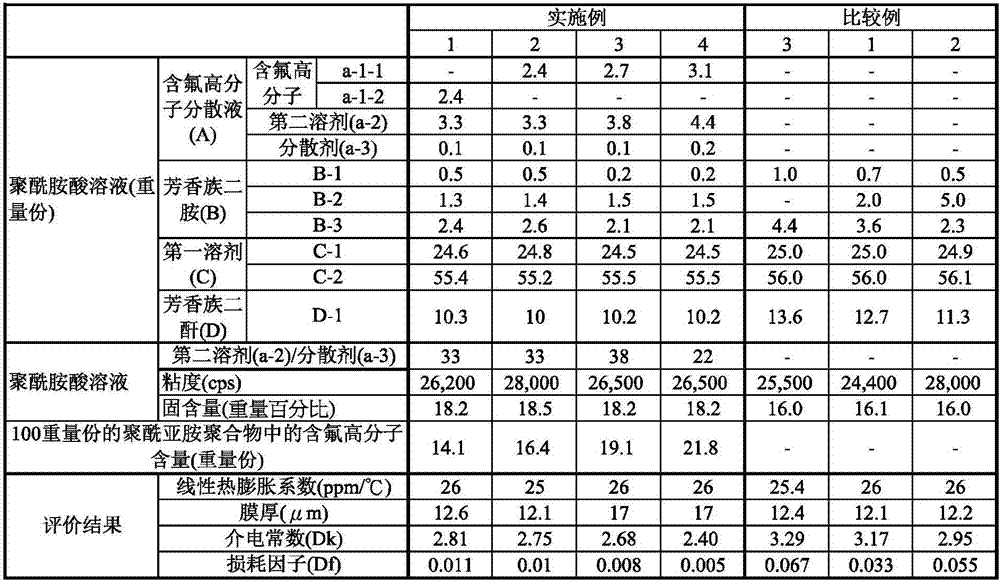

Embodiment 1

[0058] First, 2.4 parts by weight of polytetrafluoroethylene (average particle diameter of 9 μm; a-1-1) and 0.1 parts by weight of a dispersant (model BYK-164; manufactured by BYK Additives & Instruments; a-3) were dissolved in 3.3 parts by weight part of butyl acetate (a-2), and stirred at a stirring rate of 30 Hz for 2 hours to form a fluorine-containing polymer dispersion (A). In addition, 4,4'-diaminodiphenyl ether (B-1), 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl (B-2) and p-diphenylamine (B -3) Dissolve 24.6 parts by weight of N-methylpyrrolidone (C-1) and 55.4 parts by weight of dimethylacetamide (C-2) at a weight ratio of about 1:3:5, and stir evenly for 2 hours. The fluorine-containing polymer dispersion (A) and the above-mentioned aromatic diamine-containing solution are mixed to form a first mixture. After that, 10.3 parts by weight of 3,3',4,4'-biphenyltetracarboxylic dianhydride (D-1) was divided into three times and added to the first mixture every 4 hours, t...

Embodiment 2 to 4 and comparative example 1 to 3

[0061] Examples 2 to 4 and Comparative Examples 1 to 3 are carried out using the same manufacturing method as Example 1, the difference is that the process conditions and / or the content of the ingredients used are changed, which are listed in Table 1, No further details here.

[0062] Evaluation method

[0063] 1. Coefficient of Linear Thermal Expansion (CTE)

[0064] The coefficient of linear thermal expansion referred to herein is to measure the dimensional change of the polyimide films of Examples 1 to 4 and Comparative Examples 1 to 3 in a specific temperature range. The above test is carried out with a thermomechanical analyzer (model: DMA7e; brand: PerkinElmer) between 50°C and 500°C. The detailed test method is as follows: a polyimide film with a length of 25mm and a width of 13mm, Under a nitrogen atmosphere, the temperature was raised at a rate of about 20°C / min. Repeat the above steps twice to obtain the value for the second time, and calculate the average linear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com