Method for detecting abnormality of underground heat pipe network by infrared thermography coupling soil temperature/humidity

A technology of thermal pipe network and soil temperature, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficulty in accurately judging the location of leaks, background noise interference of detection signals, and damage to insulation layers, etc. Achieve the effect of improving fault diagnosis rate, reducing detection cost, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

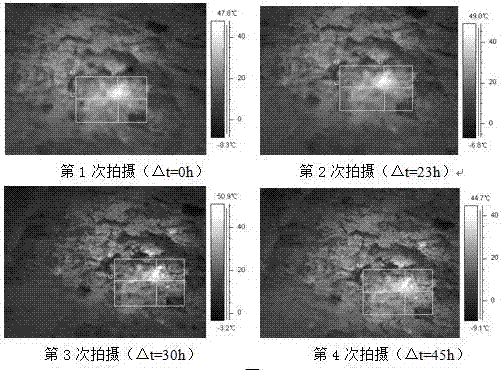

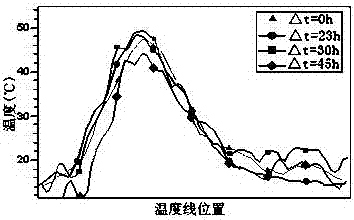

[0034] Example 1: Detection method and detection results for pipeline insulation layer damage

[0035] On January 1, 2017, infrared thermal image coupling soil temperature and humidity detection was carried out for the Gaomiao Hanhe pipeline section of Chengde City's primary heating network. The pipeline diameter is 1000mm, the buried depth is 1.5m, the water supply temperature is 110℃, and the soil is organic soil. The infrared thermal imaging lens is 3m away from the ground surface, and other parameter settings are shown in Table 1.

[0036] Table 1 Measurement parameter settings of infrared thermal imager

[0037] detection time

ambient temperature

temperature range

January 1 at 10:49

-3℃

-2℃

47%

0.95

-40℃~120℃

January 2 09:52

-7℃

-6℃

57%

0.95

-40℃~120℃

January 2 16:49

0℃

1℃

50%

0.95

-40℃~120℃

January 3rd 07:46

-8℃

...

Embodiment 2

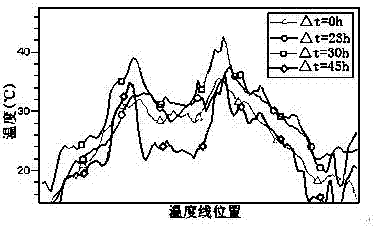

[0041] Example 2: Leak detection method and detection results of buried heat pipe network

[0042] On December 29, 2016, an infrared thermal imaging coupling soil temperature and humidity detection was carried out for the first kindergarten pipe section of the heating pipe network in Chengde City. The pipe diameter here is 100mm, the buried depth is 1.2m, and the temperature of the water supply pipe is 110°C ; Its surface is 100mm thick Dutch bricks, below the Dutch bricks is a cement mortar layer with a thickness of 100mm and a cement concrete layer with a thickness of 200mm, and then there is sandy soil below. The infrared thermal imaging lens is 3m away from the surface, and other parameter settings are shown in Table 2. .

[0043] Table 2 Infrared camera measurement parameter settings

[0044] detection time

ambient temperature

temperature range

December 29 16:19

-3℃

-1℃

41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com