Method for preparing microchannel plate from high polymer filler

A technology of microchannel plate and polymer, which is applied in the manufacture of light-emitting cathodes and secondary emitter electrodes, etc., to achieve the effects of avoiding deformation, ensuring mechanical strength, and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

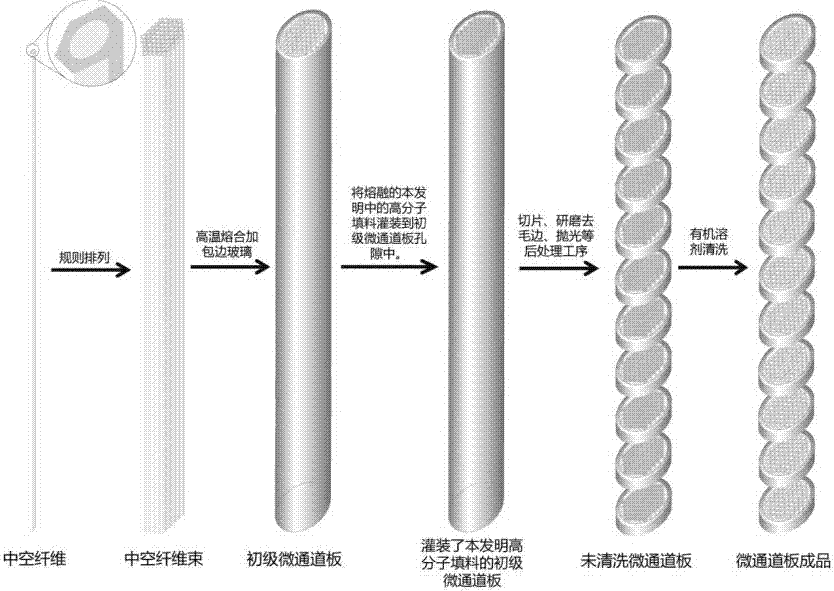

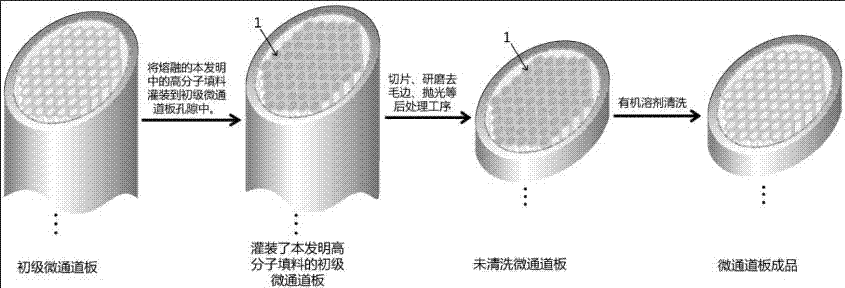

[0026] (1) Preparation of primary microchannel plate:

[0027] A number of hollow fibers are regularly arranged as regular hexagonal hollow fiber bundles, and the regular hexagonal hollow fiber bundles are fused at a temperature of 620°C, and edged glass is added to the outer surface after fusion, and the pore diameter of the obtained primary microchannel plate is 50um;

[0028] (2) Fill primary microchannel plate for post-processing:

[0029] The polymer filler was melted at a temperature of 120°C. Under the constant temperature condition of 90°C, the viscosity coefficient of the heated and melted polymer filler was measured by a rotational viscometer to be 78mPa.s, and the viscosity coefficient of the heated and melted polymer filler was The volume thermal expansion coefficient is 0.75×10 -3 / °C, fill the melted and easy-to-fill polymer filler into the primary microchannel plate; cool for a period of time until the polymer filler is solidified, the solidified polymer filler...

Embodiment 2

[0033] (1) Preparation of primary microchannel plate:

[0034] A number of hollow fibers are regularly arranged as regular hexagonal hollow fiber bundles, and the regular hexagonal hollow fiber bundles are fused at a temperature of 630°C, and edged glass is added to the outer surface after fusion, and the pore diameter of the obtained primary microchannel plate is 20um;

[0035] (2) Fill primary microchannel plate for post-processing:

[0036] Melt the polymer filler at a temperature of 120°C. Under the constant temperature condition of 90°C, the viscosity coefficient of the heated and melted polymer filler is measured by a rotational viscometer as 100mPa.s, and the viscosity coefficient of the heated and melted polymer filler is The volume thermal expansion coefficient is 0.66×10 -3 / °C, fill the melted and easy-to-fill polymer filler into the primary micro-channel plate; cool for a period of time until the polymer filler solidifies, the solidified polymer filler has greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com