High-performance GeSbTe-based thermoelectric material preparation method

A thermoelectric material and high-performance technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device junction lead-out materials, etc., can solve the problems of microstructure disorder, limit research and application, and damage to human body and environment, so as to improve Seebeck coefficient, reducing carrier concentration, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-performance GeSbTe-based thermoelectric material, comprising the steps of:

[0035] 1) Using Ge, Sb and Te simple substances as raw materials, according to Ge 0.93 Sb 0.06 The stoichiometric ratio of Te weighs each raw material, puts the weighed raw material into a quartz test tube and vacuum seals it, then puts the quartz tube into a melting furnace and heats it to 1100°C for 24 hours until the reaction is complete, and finally cools to room temperature with the furnace. Ingot product;

[0036] 2) Place the ingot product obtained in step 1) in a quartz tube with a nozzle diameter of 0.5mm, place the quartz tube above the radio frequency copper roller for induction melting, and spray the molten alloy obtained by smelting on a 10m On the copper roller that rotates at / s, a thin strip product is obtained;

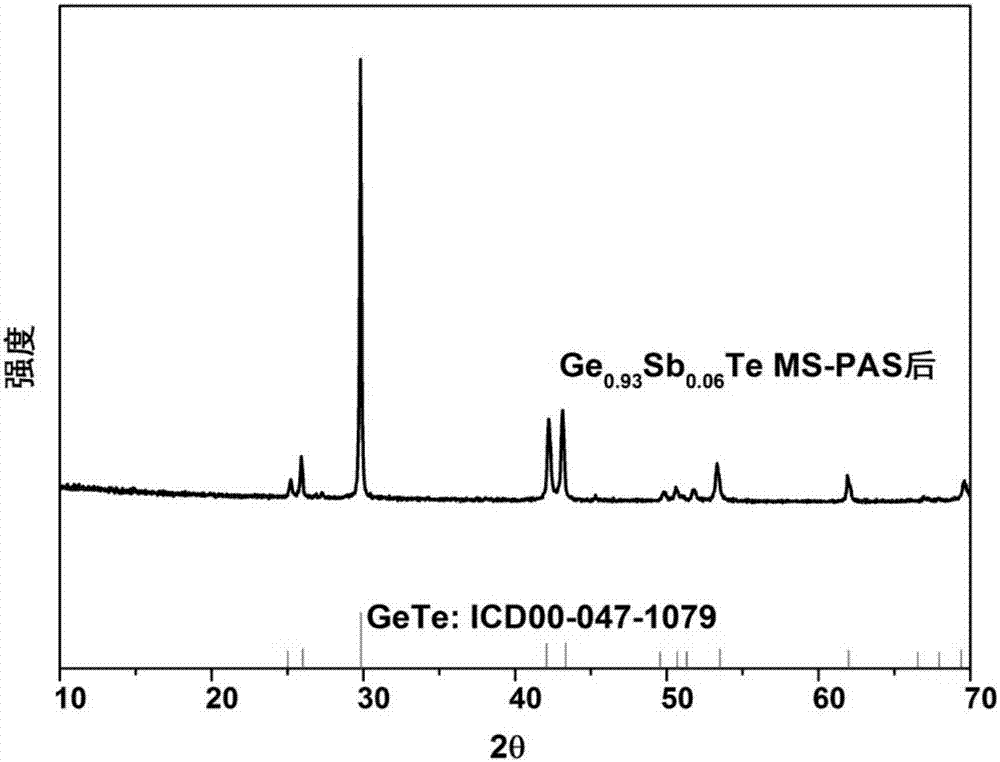

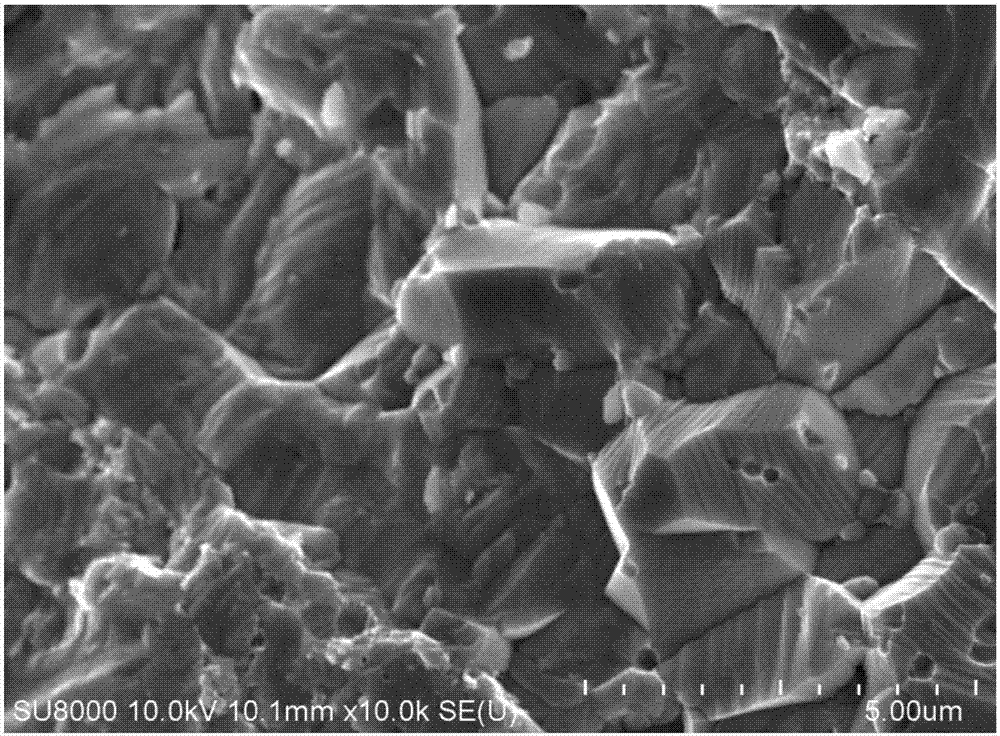

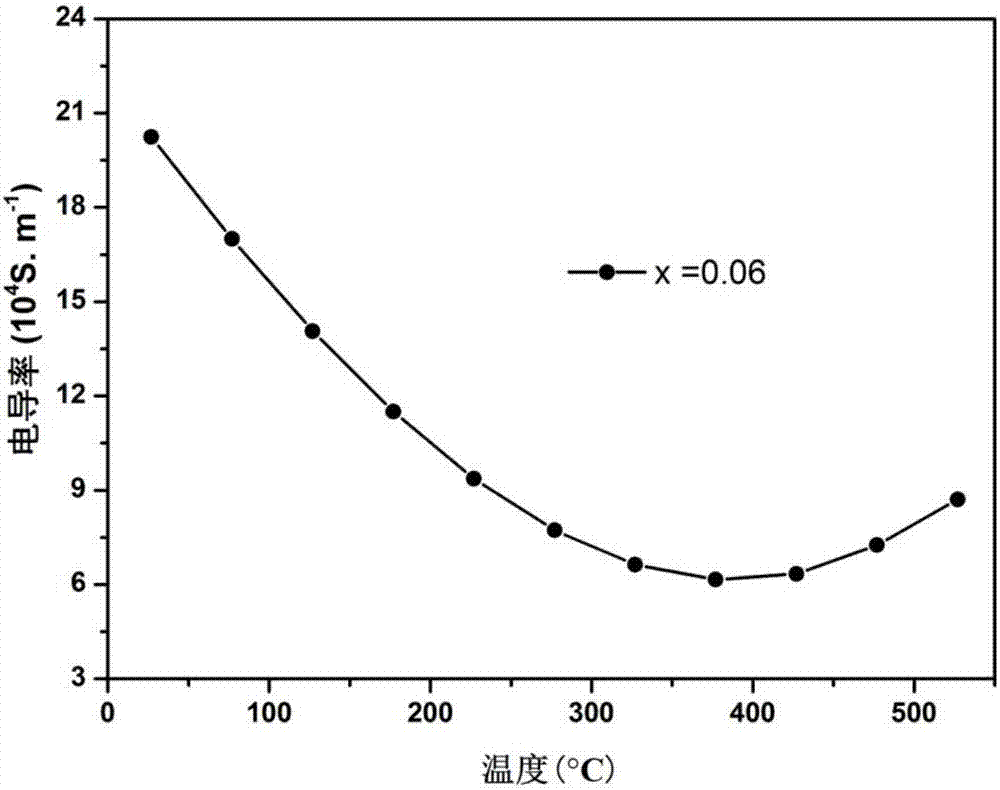

[0037] 3) Grind the strip product obtained in step 2), and then perform PAS sintering at a temperature of 500°C and a pressure of 50 M...

Embodiment 2

[0040] A method for preparing a high-performance GeSbTe-based thermoelectric material, comprising the steps of:

[0041] 1) Using Ge, Sb and Te simple substances as raw materials, according to Ge 0.98 Sb 0.01 The stoichiometric ratio of Te weighs each raw material, puts the weighed raw material into a quartz test tube and vacuum seals it, then puts the quartz tube into a melting furnace and heats it to 1100°C for 24 hours until the reaction is complete, and finally cools to room temperature with the furnace. Ingot product;

[0042] 2) Place the ingot product obtained in step 1) in a quartz tube with a nozzle of 0.5mm in diameter, and place the quartz tube above the radio frequency copper roller for induction melting. On the copper roller that rotates at / s, the thin strip product is obtained;

[0043] 3) Grinding the ribbon product obtained in step 2), and then performing PAS sintering at a temperature of 480° C. and a pressure of 52 MPa for 5 minutes to obtain a dense bloc...

Embodiment 3

[0045] A method for preparing a high-performance GeSbTe-based thermoelectric material, comprising the steps of:

[0046] 1) Using Ge, Sb and Te simple substances as raw materials, according to Ge 0.89 Sb 0.1 The stoichiometric ratio of Te weighs each raw material, puts the weighed raw material into a quartz test tube and vacuum seals it, then puts the quartz tube into a melting furnace and heats it to 1100°C for 24 hours until the reaction is complete, and finally cools to room temperature with the furnace. Ingot product;

[0047] 2) Place the ingot product obtained in step 1) in a quartz tube with a nozzle diameter of 0.5mm, place the quartz tube above the radio frequency copper roller for induction melting, and spray the molten alloy obtained by smelting on a 10m On the copper roller that rotates at / s, a thin strip product is obtained;

[0048] 3) Grinding the ribbon product obtained in step 2), and then performing PAS sintering at a temperature of 520° C. and a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com