Copper-selenium based high performance thermoelectric material and preparation method of the same

A thermoelectric material and high-performance technology, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as thermoelectric performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

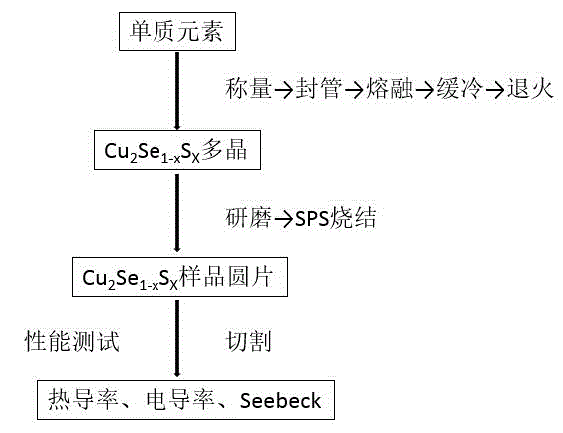

[0026] The preparation process of the present invention is realized through vacuum packaging, melting, slow cooling and annealing processes, figure 2 A process flow diagram for the preparation of this material is shown.

[0027]1) The preparation method of the present invention uses pure elemental elements as initial raw materials, which are elemental copper, elemental Se and elemental sulfur respectively. The starting material is weighed in a stoichiometric ratio 2:1-x:x and sealed in a quartz tube;

[0028] Vacuum packaging is carried out in an argon atmosphere glove box, using plasma or flame gun packaging, the quartz tube is evacuated during packaging, and the internal pressure is 1-10000Pa;

[0029] 2) The melting process is carried out in a vertical melting furnace. Melt treatment at 1100-1150°C for 12-24 hours, preferably at a heating rate of 10°C / h to 1150°C, and melt at constant temperature for 12 hours;

[0030] 3) Annealing at 600-800°C for 5-8 days, preferably ...

Embodiment 1

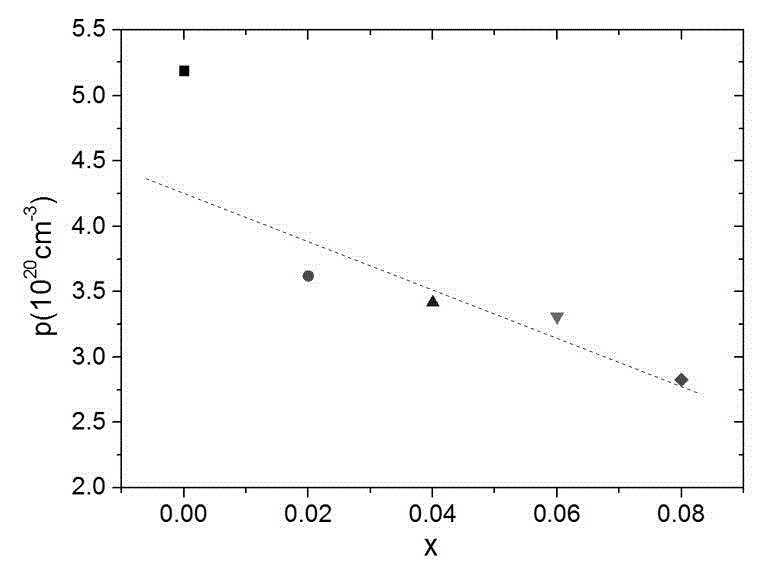

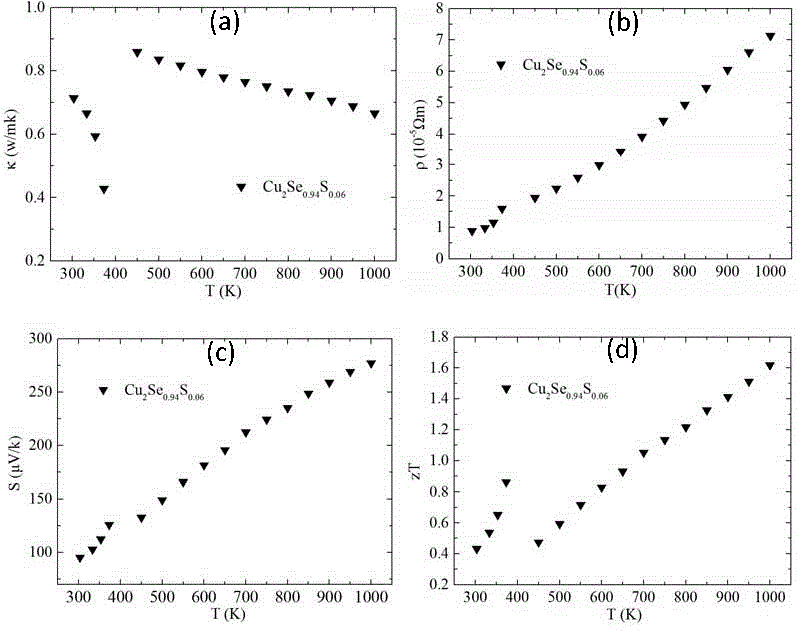

[0036] Cu 2 Se 0.94 S 0.06 (x=0.06) thermoelectric properties

[0037] The elemental raw materials Cu, Se and S were weighed at a molar ratio of 2:0.94:0.06, and then packaged in a quartz tube. Raise the temperature to 1150°C at a heating rate of 10°C / h, melt the raw material at 1150°C for 12 hours, then cool down to 800°C at a rate of 12°C / h, anneal at this temperature for 6 days, and cool to room temperature with the furnace. The annealed product is ground into powder and subjected to spark plasma sintering at a sintering temperature of 450-600°C, a pressure of 65MPa, and a sintering time of 5-10 minutes to obtain a dense bulk material. Thermoelectric performance measurements show that in the measured temperature range (300-1000K), the material has a high Seebeck coefficient and moderate electrical conductivity, and this material has a very low thermal conductivity (in the temperature range of 300-1000K, its Value- 1 K -1 ). Calculated according to the performance mea...

Embodiment 2

[0039] Cu 2 Se 0.92 S 0.08 (x=0.08) thermoelectric properties

[0040] The elemental raw materials Cu, Se and S were weighed according to the molar ratio of 2:0.92:0.08, and then packaged in a quartz tube. Raise the temperature to 1150°C at a heating rate of 10°C / h, melt the raw material at 1150°C for 12 hours, then cool down to 800°C at a rate of 12°C / h, anneal at this temperature for 6 days, and cool to room temperature with the furnace. The annealed product is ground into powder and subjected to spark plasma sintering at a sintering temperature of 450-600°C, a pressure of 65MPa, and a sintering time of 5-10 minutes to obtain a dense bulk material. Thermoelectric performance measurements show that the Seebeck coefficient of the sample with this composition is slightly higher than that of Cu 2 Se 0.94 S 0.06 , while the electrical conductivity is slightly lower, and the thermal conductivity of samples of this composition is lower than that of Cu in the corresponding tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com