Preparation method of high-dietary-fiber oleogel

A technology of high dietary fiber and oil gel, applied in the field of food science, achieves the effect of simple and convenient method, good stability, and convenient long-term storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation conditions of the drying method are: temperature: 50-90 DEG C, time: 3-10 hours. The preferred drying temperature is 50°C and the drying time is 10 hours;

[0036] The preparation conditions using the freezing method are: temperature: -25° C.; time: 5 hours.

[0037] The oil gel is obtained by adding food additives to promote the formation of gels in the emulsion. The additives are food safety approved additives. The additives calcium chloride, calcium carbonate, calcium citrate or calcium oxalate are added in an amount of 10-100mmol / g Hydrocolloid, calcium chloride is preferably added, and the addition amount is up to 50mmol / g hydrocolloid.

Embodiment 1

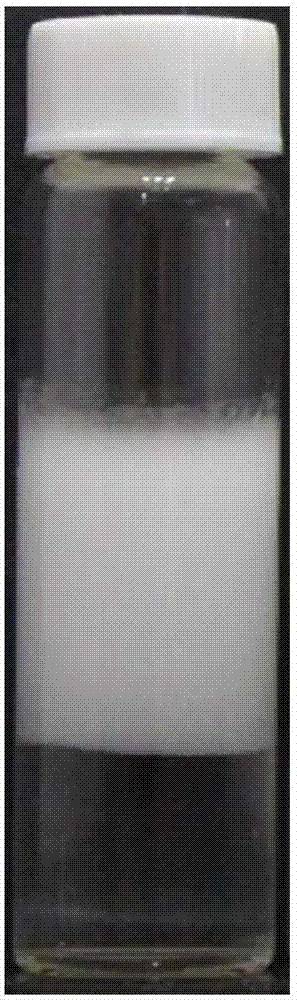

[0039] Example 1. Weigh 0.05g of microcrystalline cellulose powder with a size of 500nm prepared from pure wood pulp, add it to 100mL of distilled water, stir and dissolve at room temperature to obtain a microcrystalline cellulose aqueous dispersion solution, and then weigh 0.05g The xanthan gum powder and the aqueous cellulose dispersion solution were blended uniformly. Then, measure 10mL soybean oil and join in the mixed solution of above-mentioned cellulose and xanthan gum, stir and disperse under the rotation number of 2000rpm in the mechanical mixer for 30 minutes, prepare the oil-in-water emulsion (see figure 1 ), the oil-in-water emulsion was left to stand for 3 hours and the stratification was obvious, and the particle size distribution was observed under a microscope. The prepared emulsion was placed in a ventilated drying oven and dried at 50°C for 10 hours to obtain a high dietary fiber oil gel. The oil layer on the surface of the sample was obviously separated and ...

Embodiment 2

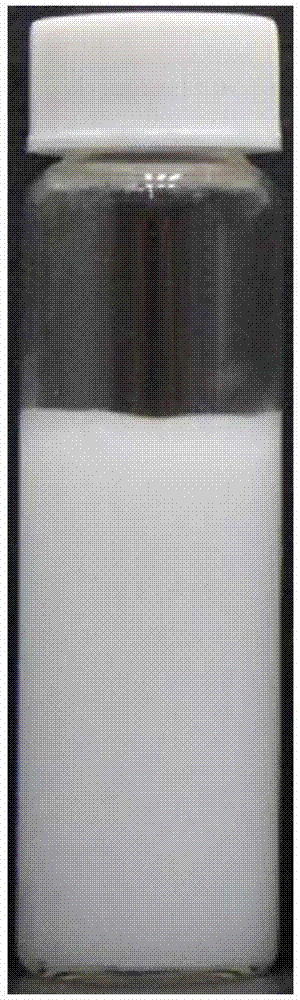

[0040] Example 2. Weigh 0.1 g of microcrystalline cellulose powder with a size of 500 nm prepared from pure wood pulp, add it to 100 mL of distilled water, stir and dissolve at room temperature to obtain a microcrystalline cellulose aqueous dispersion solution, and then weigh 0.1 g The xanthan gum powder and the aqueous cellulose dispersion solution were blended evenly. Then, measure 20mL of soybean oil and add it to the above-mentioned mixed solution of cellulose and xanthan gum, stir and disperse for 15 minutes under the rotation number of 8000rpm in a mechanical mixer to prepare an oil-in-water emulsion, and leave the oil-in-water emulsion for 3 hours That is, the stratification is obvious, and the particle size distribution is not uniform under the microscope observation. The prepared emulsion was placed in a ventilated drying oven and dried at 50°C for 10 hours to obtain a high dietary fiber oil gel. A small amount of oil layer precipitated on the surface of the sample an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com