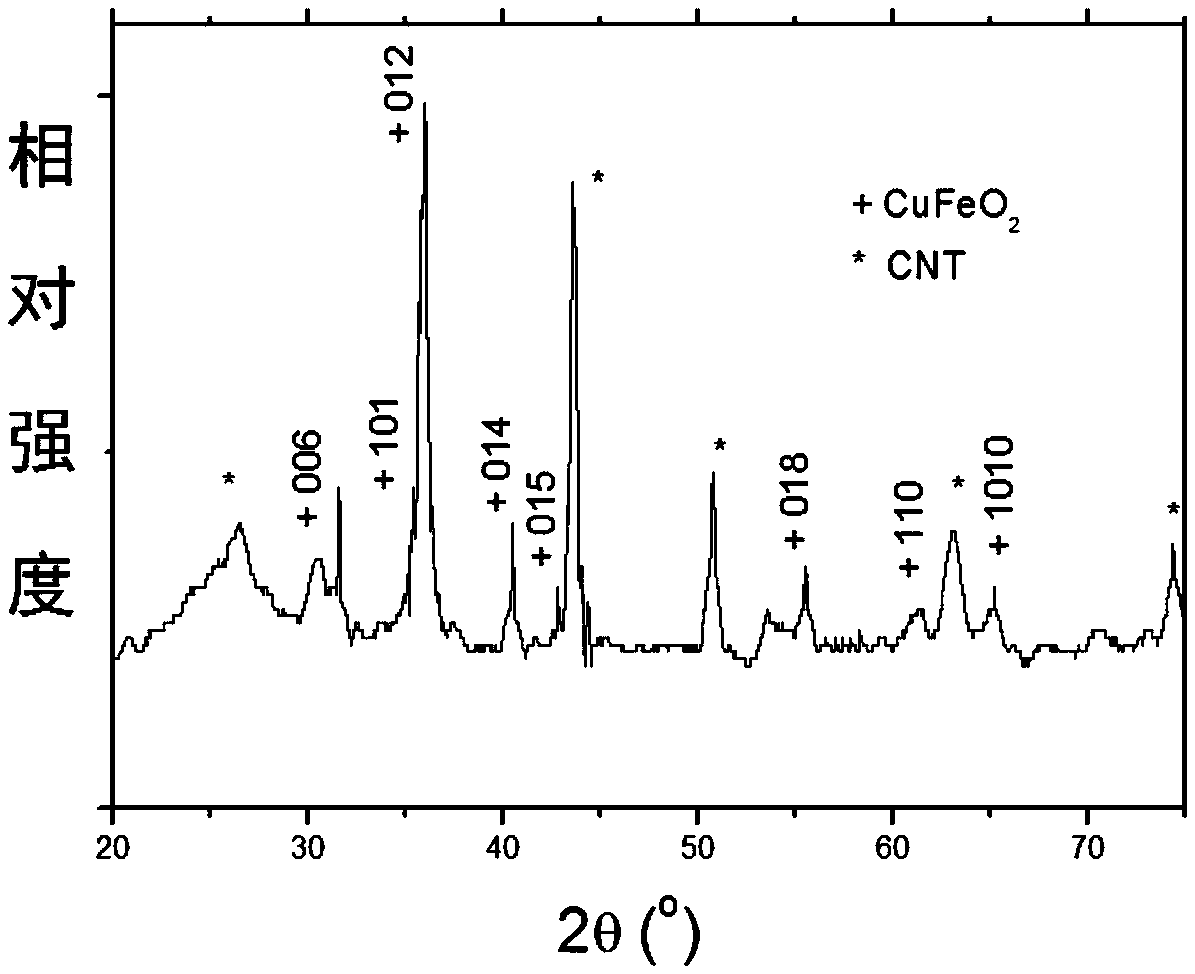

A kind of cufeo2-carbon nanotube nanocomposite and its synthesis method

A technology of nanocomposites and carbon nanotubes, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unsynthesized CuFeO2 nanomaterials, and achieve increased chemical stability, methods Simple and easy to implement, the effect of improving the ability of mass transfer and conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 2.271g of CNT and add it into 10mL of water, and disperse it by ultrasonic for 30min to form a CNT dispersion. Fe(NO 3 ) 3 9H 2 O (0.005mol, 2.02g) and Cu (NO 3 ) 2 ·3H 2 O (0.005mol, 1.21g) was fully dissolved in 20mL deionized water to form a transparent mixed solution. Subsequently, the NaOH solution of 5mol / L is slowly added dropwise to the solution under stirring, so that the pH of the mixed solution reaches more than 11. The above-mentioned CNT dispersion liquid was added to the mixed liquid, and stirred to obtain a colloidal suspension. Then, 1 mL of propionaldehyde was added to the colloidal suspension as a reducing agent, and stirring was continued for 15 min. The colloidal suspension was transferred to a 50 mL Teflon-lined hydrothermal kettle, the kettle was tightly closed, and placed in a constant temperature drying oven at 180°C for 48 hours. The reacted hydrothermal kettle was cooled to normal temperature, the supernatant was filtered off, and ...

Embodiment 2

[0031] The preparation method of Example 2 is the same as that of Example 1, except that the amount of CNT added is 6.813g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com