Preparation method for melanin

A technology of melanin and melanin precursor, which is applied in the field of melanin preparation, can solve the problems of low visible light transmittance, large melanin particle size, and difficult dispersion of composite materials, and achieve strong ultraviolet shielding ability and high visible light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

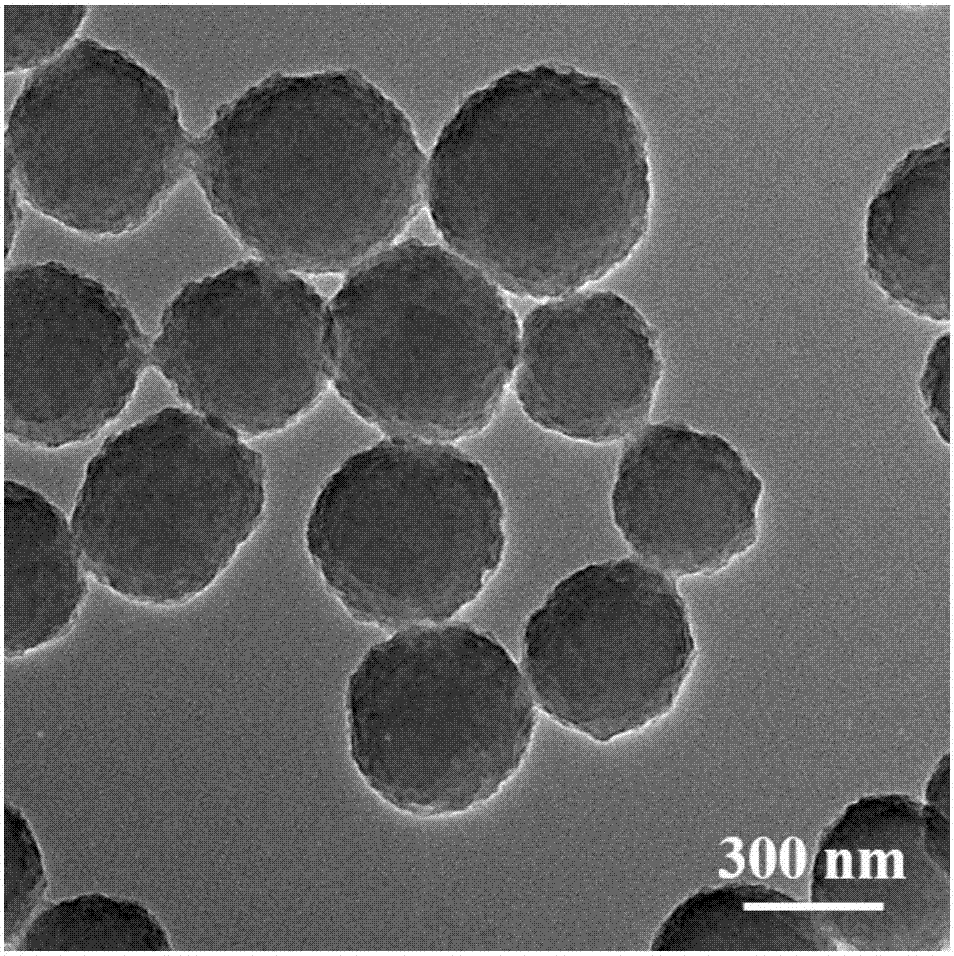

[0035] Weigh 0.18g dopamine (provided by Shanghai Aladdin Biochemical Technology Co., Ltd., specification: AR) and dissolve it in 100g of polyethylene glycol (concentration is 0.01%) (Sinopharm Chemical Reagent Co., Ltd., specification: AR) and stearin In the acid (0.01%) solution, feed 0.37g of oxygen, (the molar ratio of dopamine to oxygen is 1:10) to adjust the pH value of the solution to 8.4, 40°C, after stirring for 10 hours, the reaction is over, after centrifugation ,get melanin 1 . The average diameter is about 300nm.

Embodiment 2

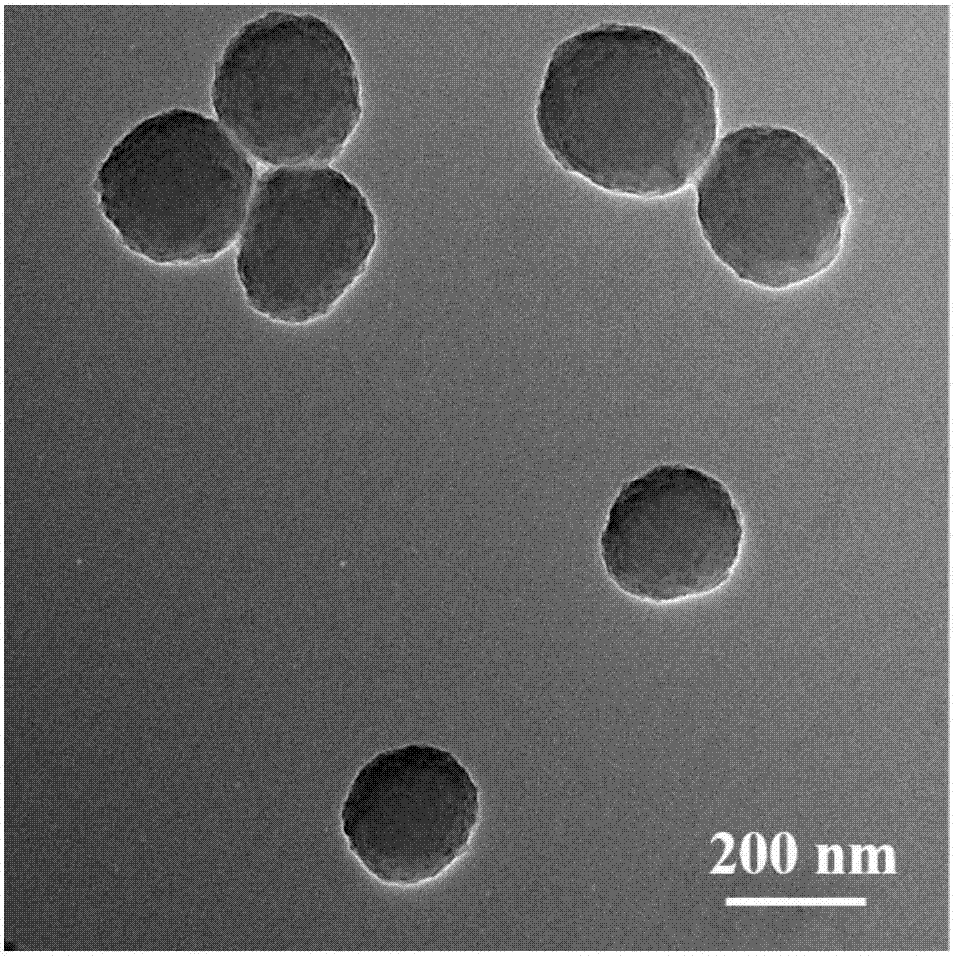

[0037] Weigh 0.2g of catechol (provided by Shanghai Aladdin Biochemical Technology Co., Ltd., specification: AR) and 2g of sodium persulfate (Sinopharm Chemical Reagent Co., Ltd., specification: AR), (catechol and persulfate The mol ratio of sodium is 1:5) is dissolved in containing 100g containing polyethylene glycol (concentration is 1%) (Sinopharm Chemical Reagent Co., Ltd., specification: AR) and sodium dodecylbenzenesulfonate (concentration is 1%) ) (Sinopharm Group Chemical Reagent Co., Ltd., specification: AR) solution (100g) in the solution, adjust the pH value of the solution to 9,60 ° C, after stirring for 5 hours, the reaction ends, through centrifugation, to obtain melanin 2 . The average diameter is about 150nm.

Embodiment 3

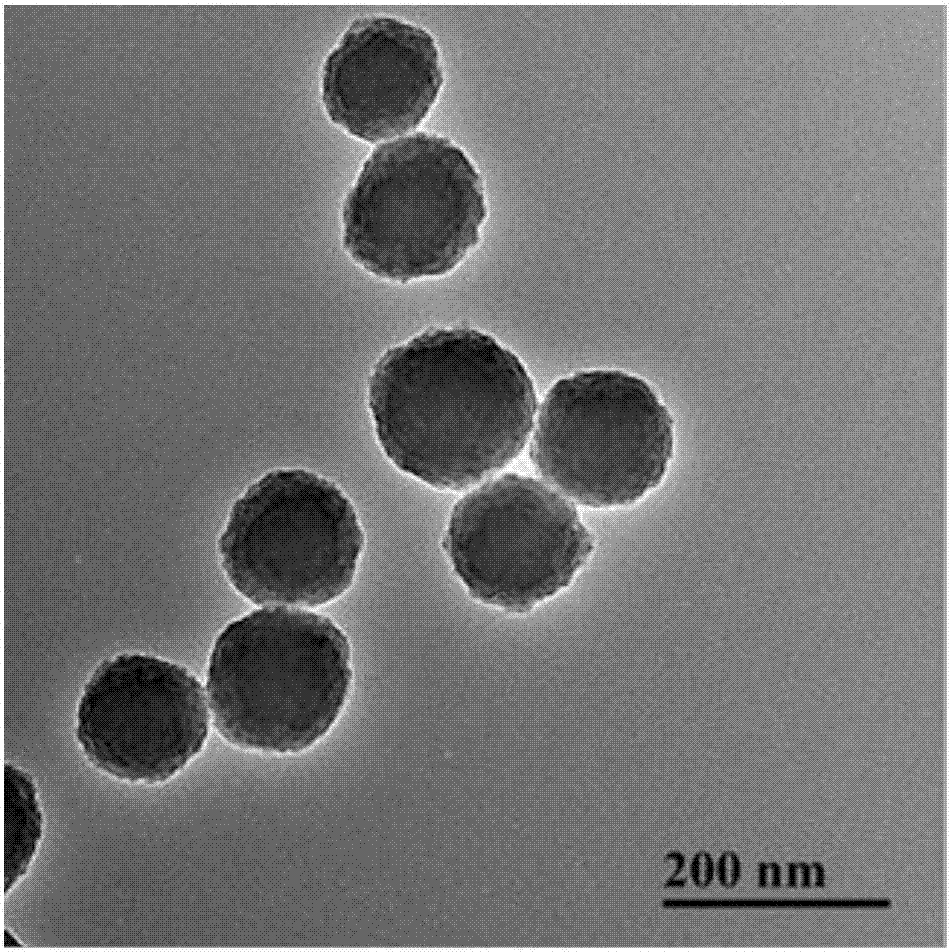

[0039] Weigh 0.2g dopa (provided by Shanghai Aladdin Biochemical Technology Co., Ltd., specification: AR) and 1.4g sodium persulfate (Sinopharm Chemical Reagent Co., Ltd., specification: AR) (the molar ratio of dopa to sodium persulfate 1:6), dissolved in 100g containing polyethylene glycol (concentration is 2%) (Sinopharm Group Chemical Reagent Co., Ltd., specification: AR) and sodium dodecylbenzenesulfonate (concentration is 1%) (Sinopharm Group Chemical Reagent Co., Ltd., specification: AR) solution, adjust the pH value of the solution to 9, 65 ° C, after stirring for 8 hours, the reaction is over, after centrifugation, to obtain melanin 3 . The average diameter is about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com