Apparatus and method for high-efficiency anaerobic biotransformation of petrochemical sludge

An anaerobic biological and petrochemical sludge technology, applied in the field of environmental engineering, can solve the problems of ineffective degradation of organic pollutants, ineffective removal of organic pollutants, lack of anaerobic biological transformation equipment, etc. Strong capability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

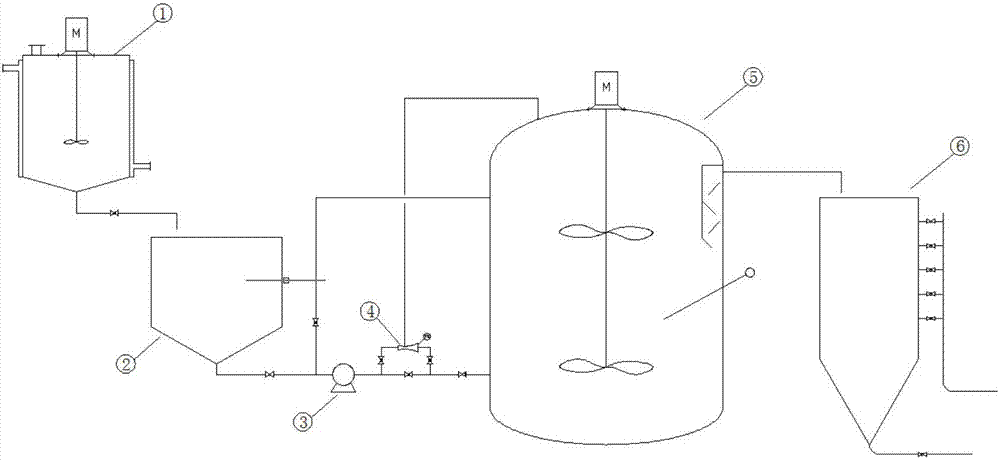

Method used

Image

Examples

Embodiment 1

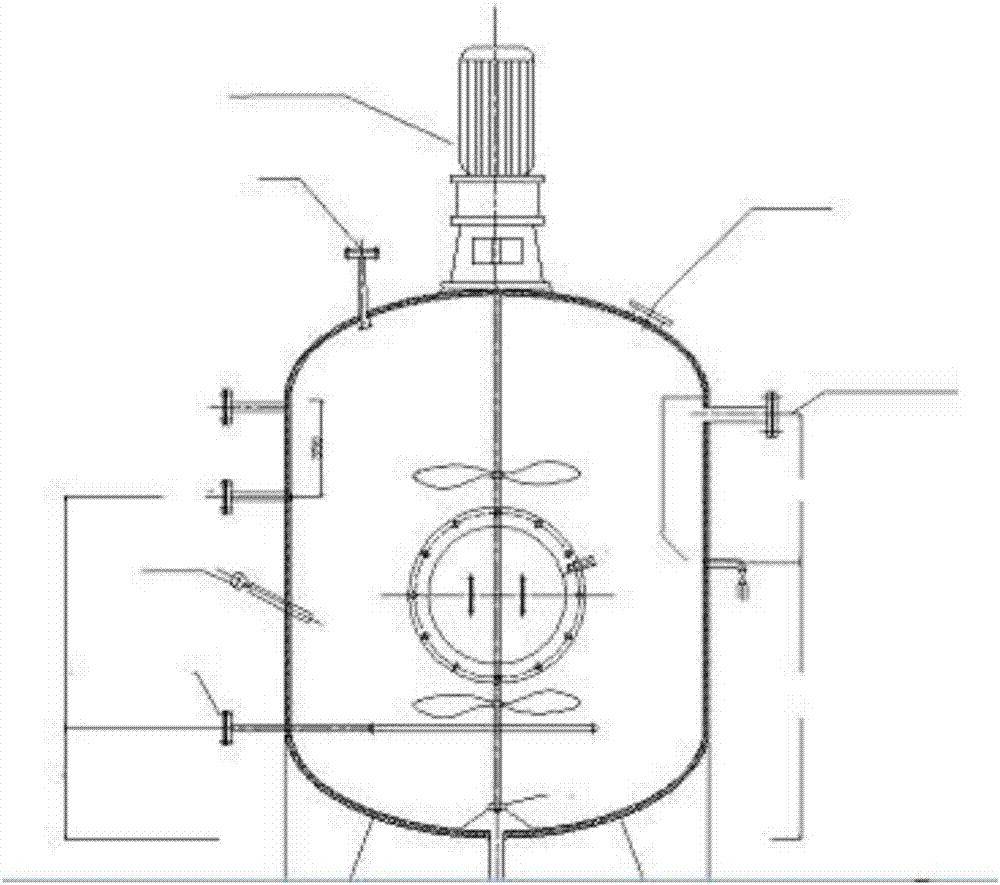

[0032] Example 1 Anaerobic digestion of petrochemical sludge in a petrochemical water plant in Nanjing, harmless, reduction and resource treatment project

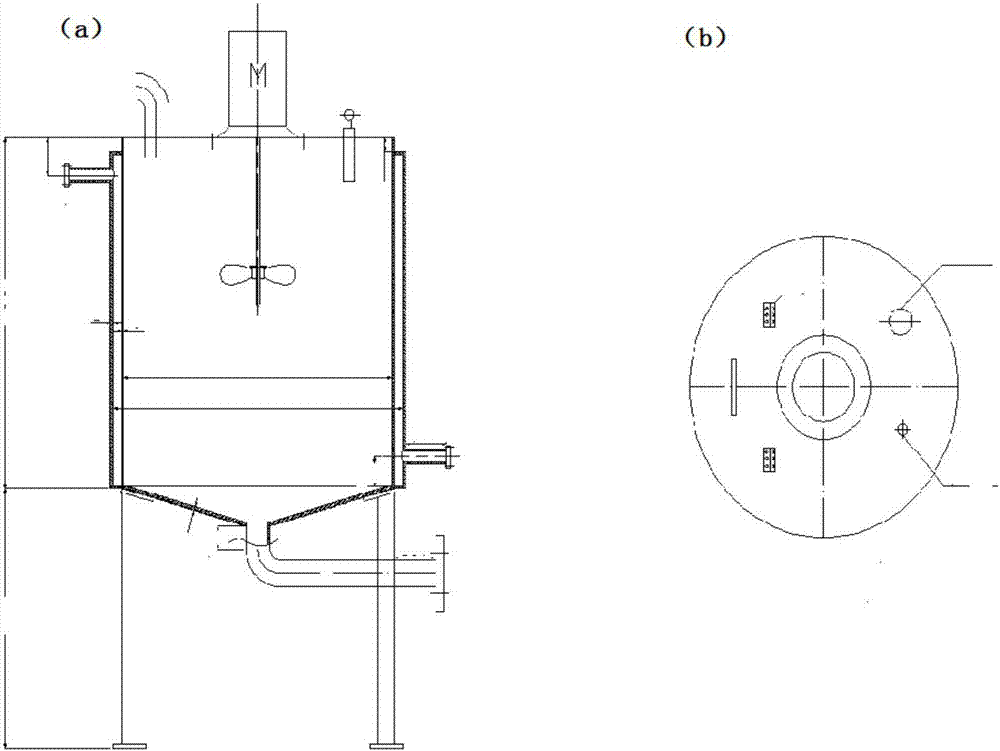

[0033] According to the method provided by the present invention, the petrochemical sludge of a petrochemical water plant in Nanjing is treated. The petrochemical wastewater of the petrochemical water plant adopts the activated sludge method, and the water content of the sludge is about 4.5% after being concentrated in a sedimentation tank. About 10 tons of petrochemical sludge with a solid content of 4.5% was taken. It was determined that the amount of organic pollutants seriously exceeded the standard, had a foul smell, and was extremely difficult to dehydrate.

[0034] A petrochemical sludge hydrothermal pretreatment in Nanjing: the pretreatment temperature is 70 degrees Celsius, the time is 20 minutes, and the hydrothermal treatment equipment is a 100L ordinary steel buffer tank. After the sludge is hydrothermally trea...

Embodiment 2

[0037] Example 2 Anaerobic digestion of petrochemical sludge in a petrochemical water plant in Nanjing, harmless, reduction and resource treatment project

[0038] Other conditions are the same as in Example 1, wherein the sludge hydrothermal pretreatment temperature is 75 degrees Celsius, and the time is 20 minutes. Using the same test method to test the effect of the invention, the total volatile solids of petrochemical sludge can be reduced by 50.35%, the content of organic pollutants can be reduced by 50.02%, and the dewatering performance of sludge can be increased by 2.1 times.

Embodiment 3

[0039] Example 3 Anaerobic digestion of petrochemical sludge in a petrochemical water plant in Nanjing, harmless, reduction and resource treatment project

[0040] Other conditions are the same as in Example 1, wherein the sludge hydrothermal pretreatment temperature is 75 degrees Celsius, and the time is 30 minutes. Using the same test method to test the effect of the invention, the reduction of total volatile solids of petrochemical sludge reaches 51%, the content of organic pollutants decreases by 50.32%, and the dehydration performance of sludge is improved by 2 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com