Compressive and fireproof insulating brick and preparation method thereof

A technology of refractory insulation bricks and refractory clay, which is applied in the field of refractory materials, can solve the problems of low compressive strength, short service life, poor refractoriness, etc., and achieve the effects of high compressive strength, increased strength and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

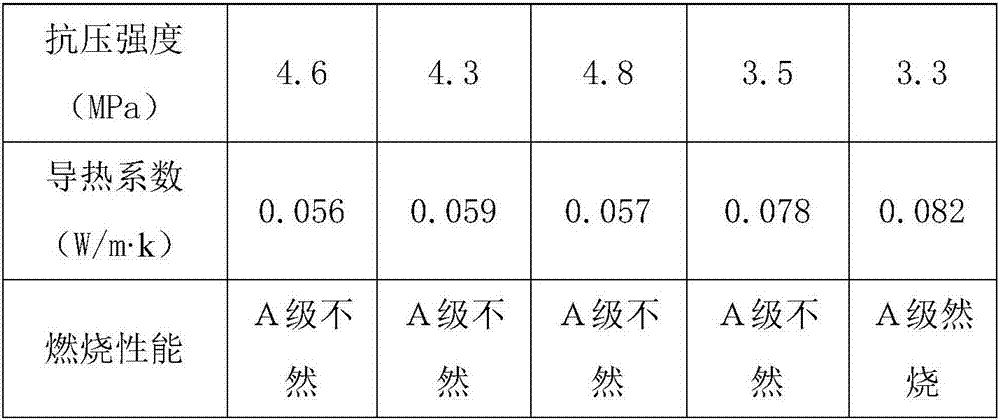

Embodiment 1

[0025] A compression-resistant refractory insulation brick prepared from the following raw materials in parts by weight: 30 parts of corundum mullite, 15 parts of quartz sand, 30 parts of expanded perlite, 12 parts of vermiculite, 5 parts of silicon carbide micropowder, floating beads 6 parts, 3.5 parts of silica micropowder, 5 parts of titanium dioxide, 7 parts of refractory clay, 1 part of foaming agent and 50 parts of water.

[0026] Wherein, the floating beads are composed of silicon dioxide and aluminum oxide in a mass ratio of 3:1.

[0027] Wherein, the mass percentage of aluminum oxide in the refractory clay is 40%.

[0028] Wherein, the foaming agent is one of sodium carbonate, magnesium carbonate, sodium bicarbonate and carbon powder.

[0029] A preparation method of a compression-resistant refractory insulation brick, comprising the following steps:

[0030] (1) Grind corundum mullite, quartz sand, expanded perlite, vermiculite, silicon carbide micropowder, floatin...

Embodiment 2

[0038] A compression-resistant refractory insulation brick prepared from the following raw materials in parts by weight: 20 parts of corundum mullite, 10 parts of quartz sand, 25 parts of expanded perlite, 8 parts of vermiculite, 2 parts of silicon carbide micropowder, floating beads 3 parts, 1 part of silica micropowder, 2 parts of titanium dioxide, 4 parts of refractory clay, 0.5 parts of foaming agent and 40 parts of water.

[0039] Wherein, the floating beads are composed of silicon dioxide and aluminum oxide in a mass ratio of 2:1.

[0040] Wherein, the mass percentage of aluminum oxide in the refractory clay is 30%.

[0041] Wherein, the foaming agent is one of sodium carbonate, magnesium carbonate, sodium bicarbonate and carbon powder.

[0042] A preparation method of a compression-resistant refractory insulation brick, comprising the following steps:

[0043] (1) Grind corundum mullite, quartz sand, expanded perlite, vermiculite, silicon carbide micropowder, floating...

Embodiment 3

[0051] A compression-resistant refractory insulation brick prepared from the following raw materials in parts by weight: 40 parts of corundum mullite, 20 parts of quartz sand, 35 parts of expanded perlite, 15 parts of vermiculite, 8 parts of silicon carbide micropowder, floating beads 10 parts, 6 parts of silica micropowder, 8 parts of titanium dioxide, 10 parts of refractory clay, 1.5 parts of foaming agent and 60 parts of water.

[0052] Wherein, the floating beads are composed of silicon dioxide and aluminum oxide in a mass ratio of 4:1.

[0053] Wherein, the mass percentage of aluminum oxide in the refractory clay is 50%.

[0054] Wherein, the foaming agent is one of sodium carbonate, magnesium carbonate, sodium bicarbonate and carbon powder.

[0055] A preparation method of a compression-resistant refractory insulation brick, comprising the following steps:

[0056] (1) Grind corundum mullite, quartz sand, expanded perlite, vermiculite, silicon carbide micropowder, floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com