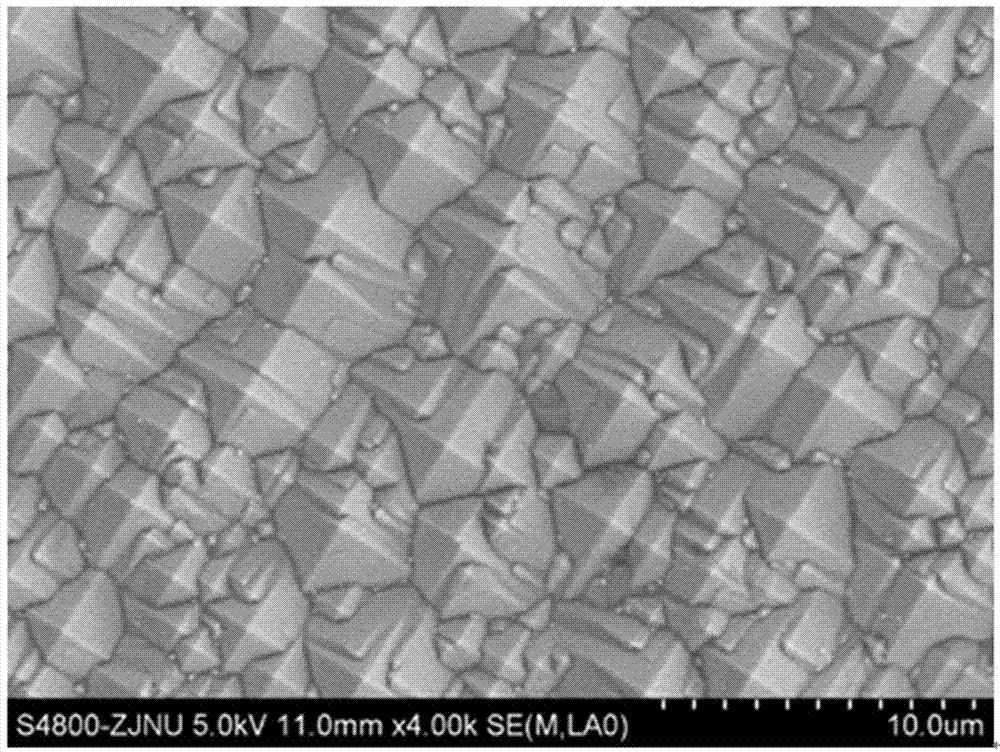

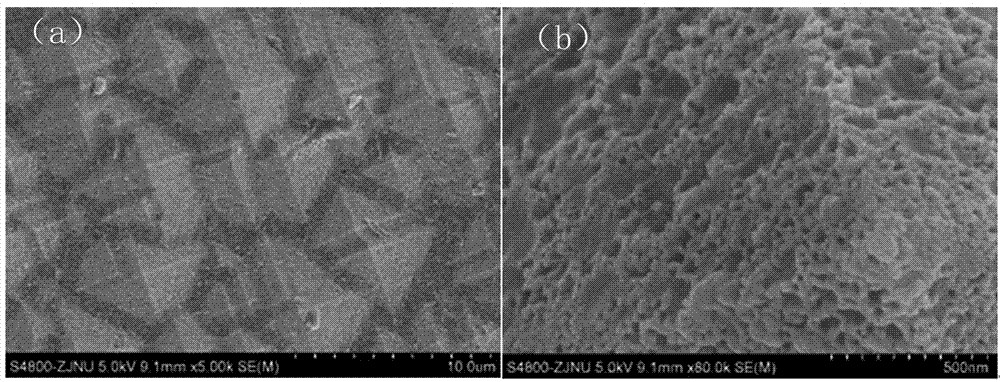

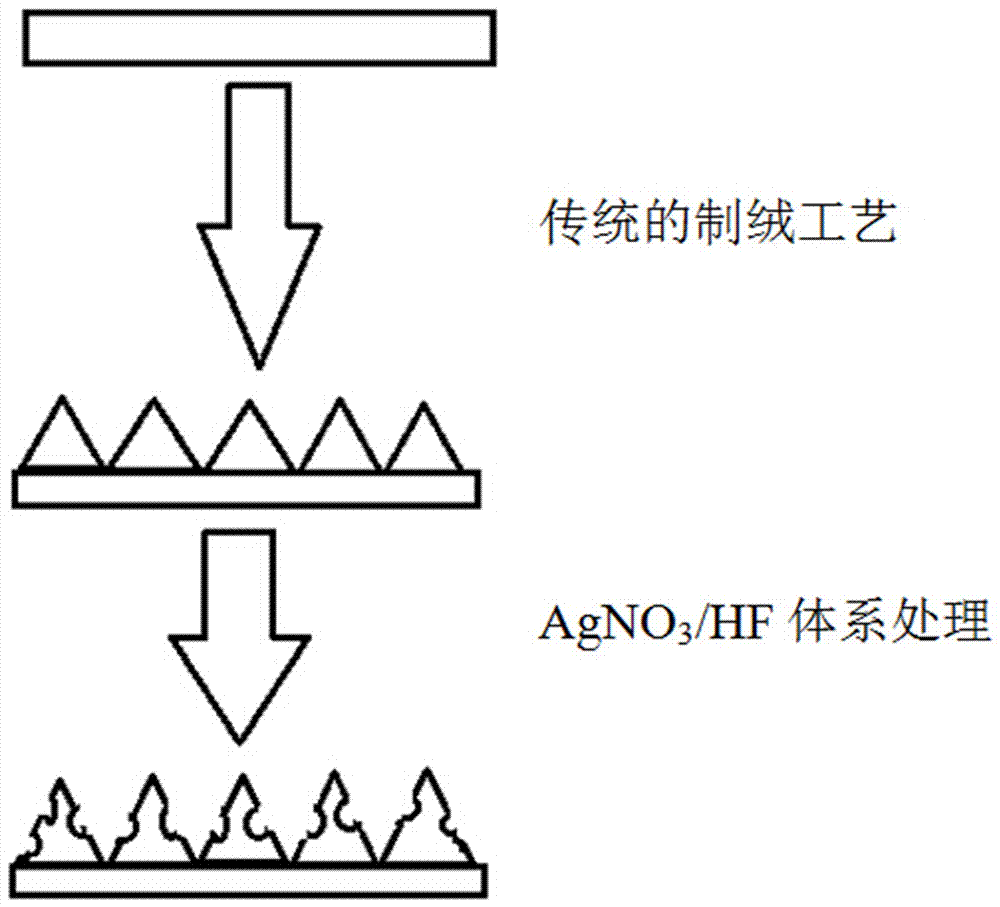

Method for preparing single-crystal silicon texture-surface structure with low reflectivity

A low-reflectivity, silicon suede technology, applied in the field of silicon chemistry, can solve the problems of the decrease of the lifespan of the minority carrier of the silicon wafer and the serious damage to the surface of the silicon wafer, and achieve the effect of improving the photoelectric conversion efficiency and reducing the reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0021] 1.1 Raw materials required:

[0022] P-type monocrystalline silicon wafer: crystal plane (100), resistivity 5Ω.cm, thickness 0.4mm, diameter 2 inches.

[0023] Chemical reagents: acetone, absolute ethanol, NaOH, isopropanol, hydrofluoric acid, AgNO 3 , NH 3 OH, hydrochloric acid, H 2 o 2 . Manufacturer: Shanghai Sinopharm.

[0024] 1.2 Main testing instruments:

[0025] Scanning electron microscope (SEM), ultraviolet-visible spectrophotometer, minority carrier lifetim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com