Sodium-sulfur battery positive electrode material and preparation method therefor

A positive electrode material, sodium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve battery component sealing technology, high technical requirements for anti-corrosion electrode materials, unable to adapt to the requirements of portability, sodium-sulfur battery Capacitance decline and other problems, to achieve good charge and discharge stability, inhibition of dissolution, the effect of a large reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

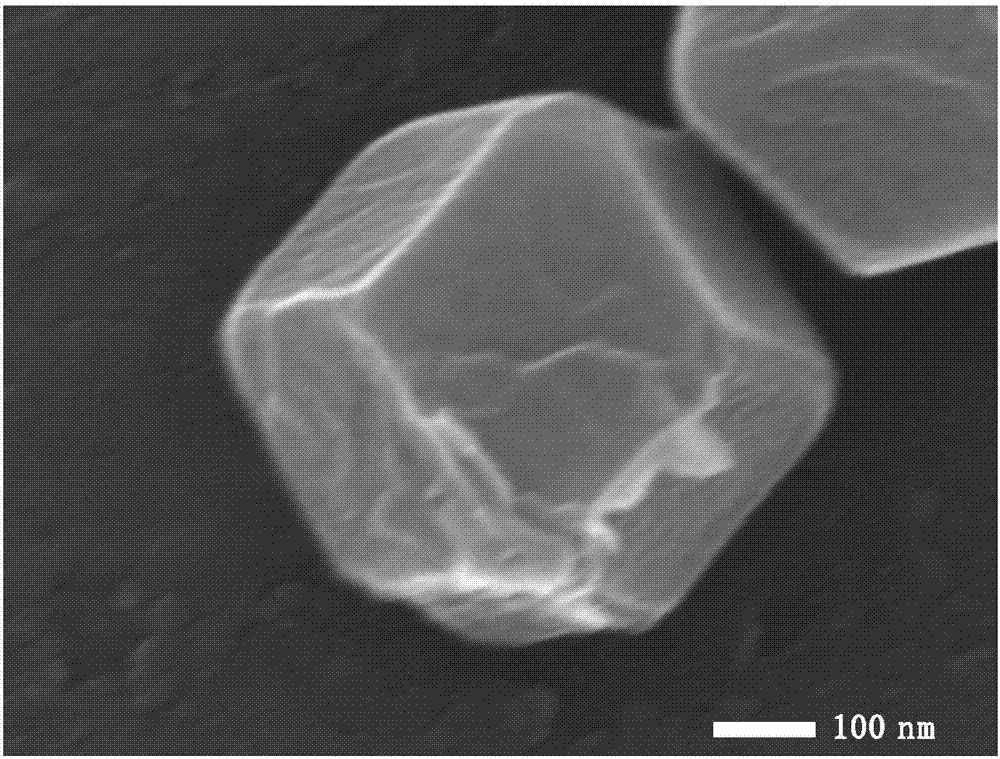

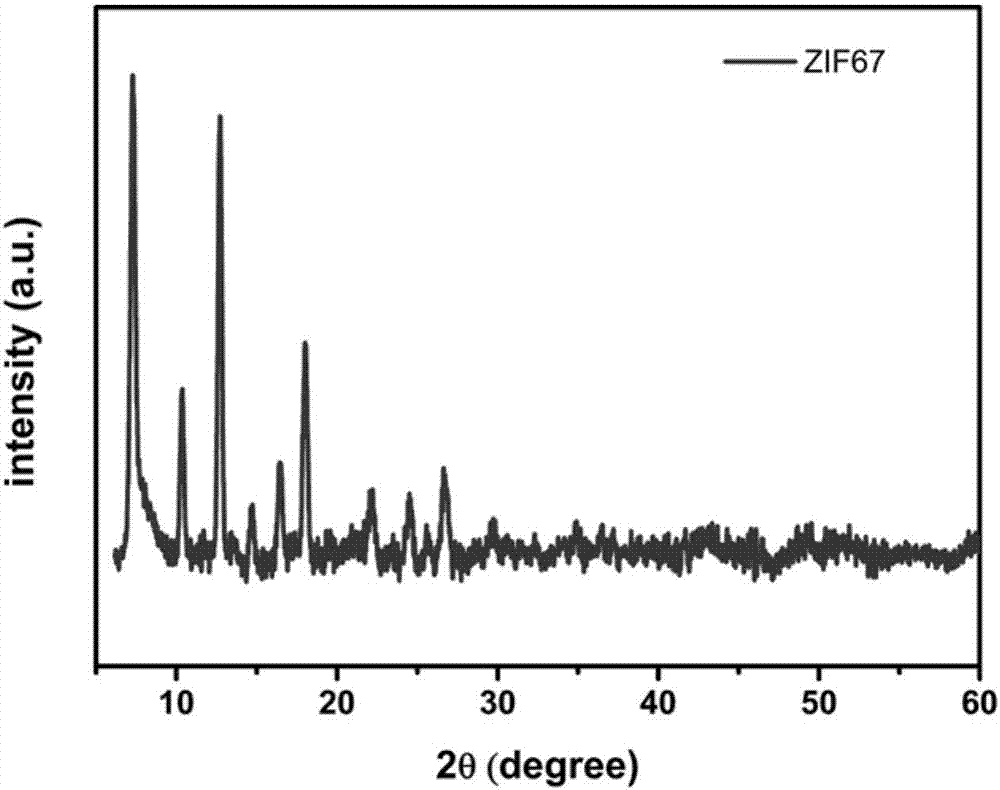

[0036] 1) Add 1.164 g of cobalt nitrate hexahydrate into 50 mL of methanol solution, and stir at room temperature and normal pressure for 10 minutes until cobalt nitrate hexahydrate is completely dissolved in the anhydrous methanol solution to obtain solution A;

[0037] 2) Add 1.314g of 2-methylimidazole into 50mL of methanol solution, stir until completely dissolved to obtain solution B, after that, pour solution A into solution B, after it is completely mixed, stop stirring, and then dissolve the solution Place it in a ventilated place and let it stand for 24 hours;

[0038] 3) The product obtained in the previous step is centrifuged and washed with anhydrous methanol, and dried to obtain the ZIF67 precursor for subsequent use;

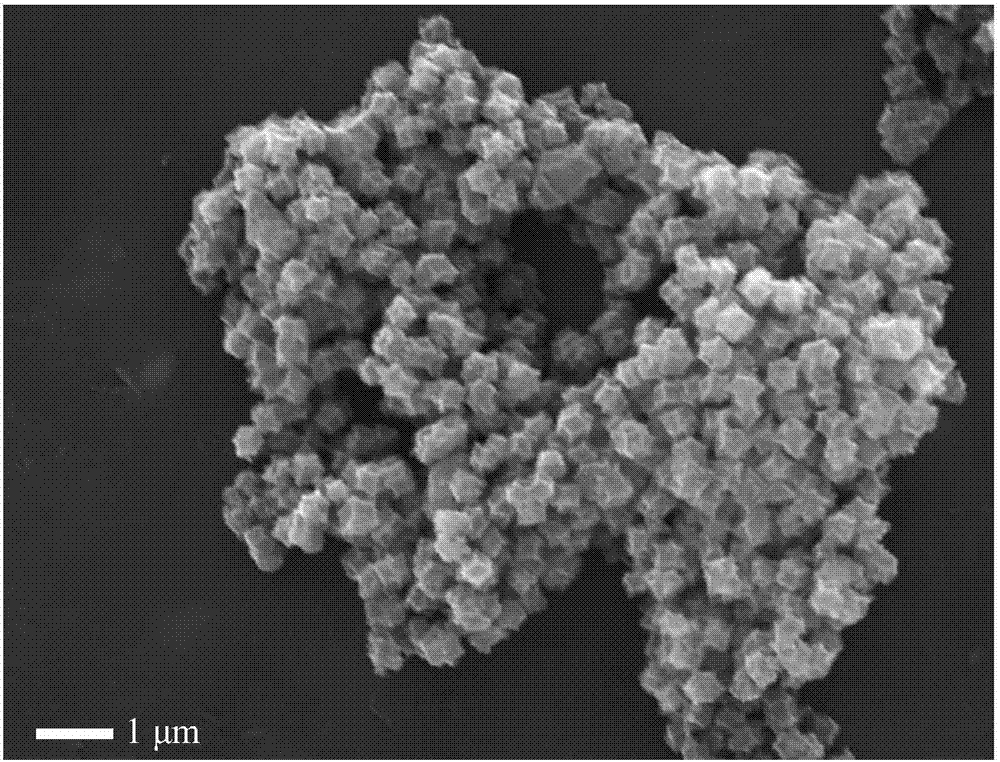

[0039] 4) The obtained precursor was heated up to 700°C at 5°C / min under nitrogen atmosphere, kept at this temperature for 6h, cooled to room temperature and taken out;

[0040] 5) Mix the obtained material with sulfur at a ratio of 1:3, and after...

Embodiment 2

[0047] 1) Add 2.328 g of cobalt nitrate hexahydrate into 50 mL of methanol solution, and stir at room temperature and normal pressure for 10 minutes until cobalt nitrate hexahydrate is completely dissolved in the anhydrous methanol solution to obtain solution A;

[0048] 2) Add 2.628g of 2-methylimidazole into 50mL of methanol solution, stir until completely dissolved to obtain solution B, after that, pour solution A into solution B, after it is completely mixed, stop stirring, and then dissolve the solution Place it in a ventilated place and let it stand for 24 hours;

[0049] 3) The product obtained in the previous step is centrifuged and washed with anhydrous methanol, and dried for subsequent use;

[0050] 4) The obtained precursor was heated up to 700°C at 5°C / min under nitrogen atmosphere, kept at this temperature for 6h, cooled to room temperature and taken out;

[0051] 5) The obtained material was mixed with sulfur at a ratio of 1:1, and after manual grinding for 20 ...

Embodiment 3

[0054] 1) Add 4.656 g of cobalt nitrate hexahydrate into 50 mL of methanol solution, and stir at room temperature and normal pressure for 10 minutes until cobalt nitrate hexahydrate is completely dissolved in the anhydrous methanol solution to obtain solution A;

[0055] 2) Add 5.256g of 2-methylimidazole into 50mL methanol solution, stir until completely dissolved to obtain solution B, after that, pour solution A into solution B, after it is completely mixed, then place the solution in a ventilated Place, stand still for 24h;

[0056] 3) The product obtained in the previous step is centrifuged and washed with anhydrous methanol, and dried for subsequent use;

[0057] 4) The obtained precursor was heated up to 700°C at 5°C / min under nitrogen atmosphere, kept at this temperature for 6h, cooled to room temperature and taken out;

[0058] 5) The obtained material was mixed with sulfur at a ratio of 1:2, and after manual grinding for 20 minutes, it was heat-treated at 155°C for 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com