Method for preparing unpolished rice noodles by dry-process micro-grinding

A technology for micro-grinding and brown rice, which is applied in the field of preparing brown rice noodles by dry micro-grinding, can solve the problems of small types and yields of brown rice noodles, rough taste of brown rice noodles, and high gelatinization temperature, so as to expand production and sales channels and improve cooking quality. , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A kind of dry method micro-grinding prepares the method for brown rice noodle

[0028] A method for dry finely pulverizing brown rice noodles, comprising the following steps:

[0029] 1) brown rice pretreatment: take 20kg of early indica brown rice, wash with pure water, remove floating ash and mixed gravel and other sundries;

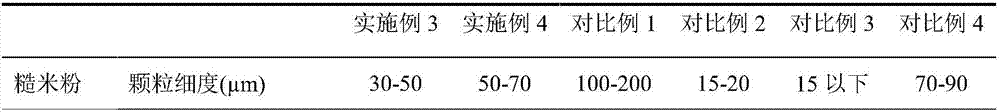

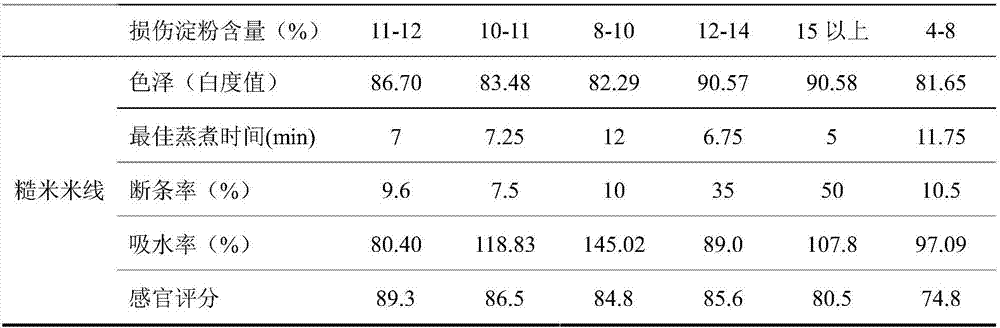

[0030] 2) Micro-grinding of brown rice: pulverize the brown rice with a common needle mill, and then use an airflow mill to pulverize the brown rice until the particle size is between 30-50 μm, and control the damaged starch content between 11%-12%;

[0031] 3) Wetting: adjust the moisture content of the brown rice flour to between 35-40%, and wetting at normal temperature for 8 hours;

[0032] 4) Self-cooked extruded strips and extruded silk: a single-screw self-cooked extruder is used to gelatinize the brown rice flour and then extrude the silk and then cool;

[0033] 5) Aging: Aging in a 20°C incubator for 4 hours;

[0034] 6)...

Embodiment 2

[0037] Embodiment 2 A method of preparing brown rice noodles by dry pulverization

[0038] A method for dry finely pulverizing brown rice noodles, comprising the following steps:

[0039] 1) brown rice pretreatment: take 20kg of early indica brown rice, wash with pure water, remove floating ash and mixed gravel and other sundries;

[0040] 2) Micro-grinding of brown rice: pulverize the brown rice with a common pin mill, and then use a jet mill to pulverize the brown rice until the particle size is between 50 and 70 μm, and control the damaged starch content between 10% and 11%;

[0041] 3) Wetting: adjust the moisture content of the brown rice flour to between 35-40%, and moisten at room temperature for 6 hours;

[0042] 4) Self-cooked extruded strips and extruded silk: a single-screw self-cooked extruder is used to gelatinize the brown rice flour and then extrude the silk and then cool;

[0043] 5) Aging: Aging in a 50°C incubator for 8 hours;

[0044] 6) Re-steaming: re-s...

Embodiment 3

[0047] Embodiment 3 A kind of dry method micro-pulverization prepares the method for brown rice noodle

[0048] A method for dry finely pulverizing brown rice noodles, comprising the following steps:

[0049] 1) brown rice pretreatment: take 20kg of early indica brown rice, wash with pure water, remove floating ash and mixed gravel and other sundries;

[0050] 2) Micro-grinding of brown rice: pulverize the brown rice with a common needle mill, and then use an airflow mill to pulverize the brown rice until the particle size is between 30-50 μm, and control the damaged starch content between 11%-12%;

[0051] 3) Wetting: adjust the moisture content of the brown rice flour to between 35-40%, and wet it for 4 hours under normal temperature conditions;

[0052] 4) Self-cooked extruded strips and extruded silk: a single-screw self-cooked extruder is used to gelatinize the brown rice flour and then extrude the silk and then cool;

[0053] 5) Aging: Aging in a 40°C incubator for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com