Unsymmetrical ring blank precise high-efficiency cold-extruding forming method

一种冷挤压、非对称的技术,应用在金属材料涂层工艺等方向,能够解决设备投入高、成形困难、加工效率低等问题,达到设备投入成本低、减少环境温度、降低工艺能耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

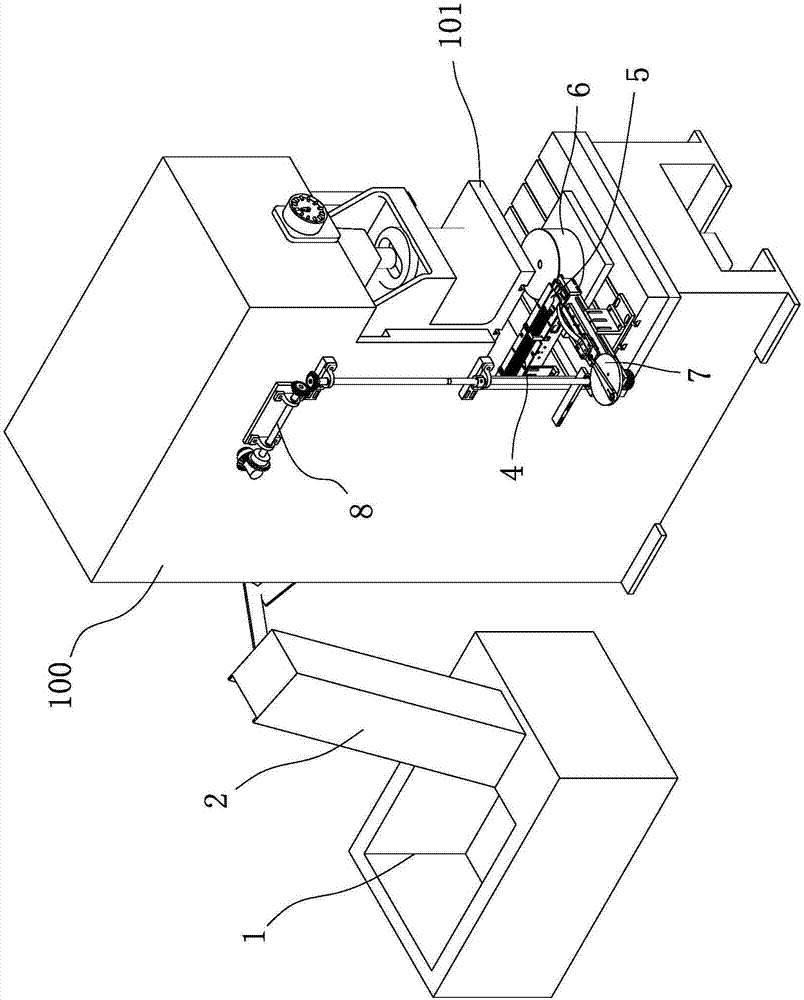

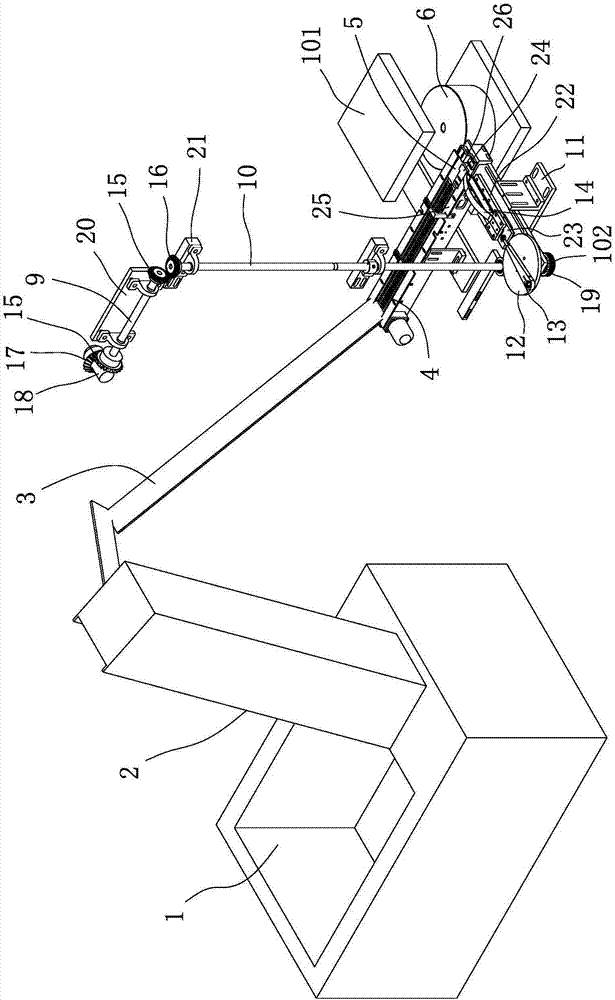

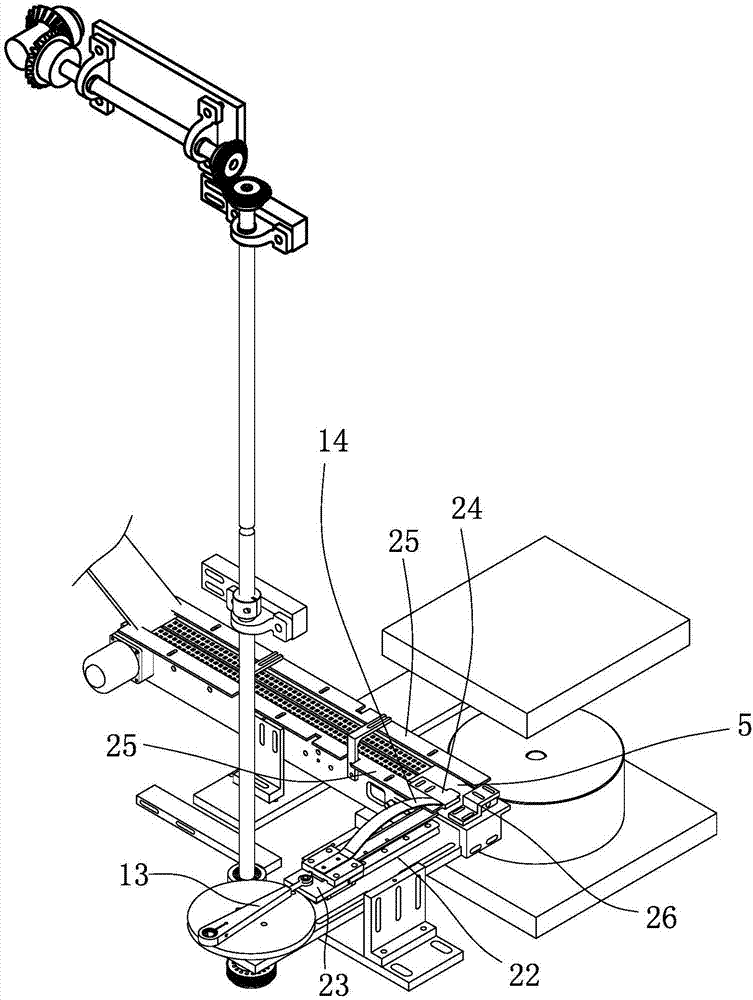

[0034] A precise and high-efficiency cold extrusion forming method for an asymmetric ferrule blank, comprising

[0035] Cutting tube cutting, surface phosphorus saponification treatment, ferrule cold extrusion forming and post-turning processing steps, characterized in that,

[0036] In the surface phosphorus saponification treatment step, the surface of the ferrule blank is first shot blasted with a shot blasting machine, and then the steps of water washing, phosphating, water washing, saponification and drying are completed in sequence.

[0037] In the cold extrusion forming step of the ferrule, an automatic feeding machine is used for loading, and the material is sent to a cold extrusion punching machine for cold extrusion.

[0038] In the tube cutting and blanking step, the tube is cut with a tube cutter to obtain a ferrule blank. The tube cutter is equipped with a chamfering device, which chamfers the inner and outer sides of the car while cutting the tube.

[0039] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com