Electric aluminum suitable for low-temperature hot stamping and preparation method thereof

A technology of anodized aluminum and low softening point, which is applied in the direction of temperature recording method, cellulose derivative adhesive, non-polymer adhesive additive, etc., can solve the problem of high temperature, reduce scrap rate, reduce cost, avoid The effect of severe moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of above-mentioned electrochemical aluminum provided by the present invention comprises the following steps:

[0052] Provide a base layer.

[0053] Coat the release agent on one side of the base layer, the dry coating amount of the release agent is 0.05~0.3g / m 2 , and dried to obtain a release layer.

[0054] Coat alcohol-soluble color ink on the side of the release layer away from the base layer, 0.5-5.0g / m of alcohol-soluble color ink 2 , and dried to obtain the color layer.

[0055] The aluminum layer is made by plating aluminum on the side of the color layer away from the release layer.

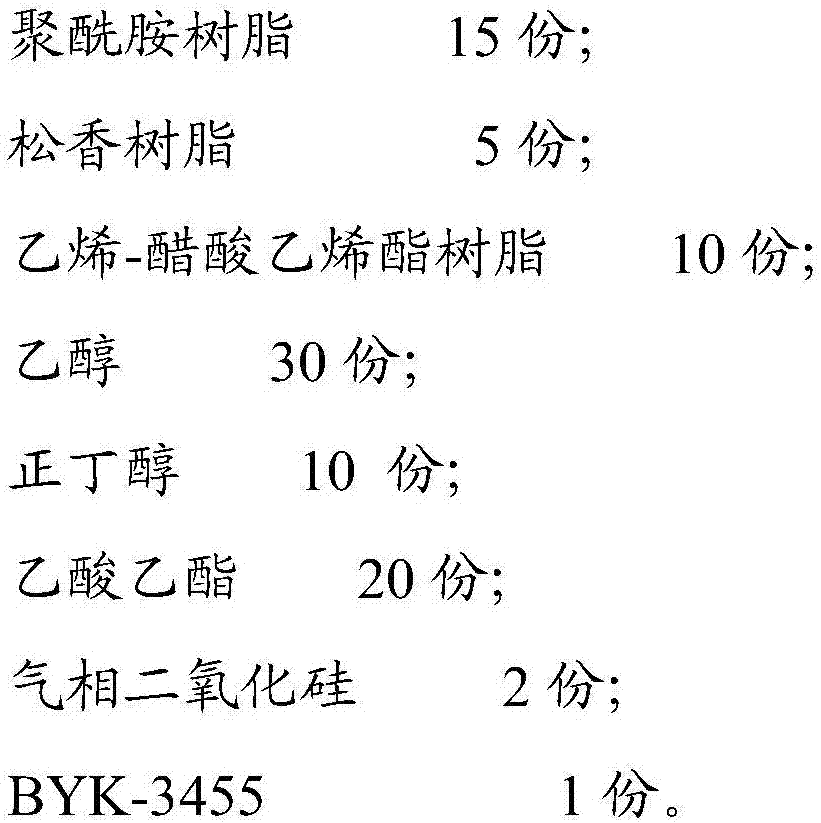

[0056] Coat the glue solution on the side of the aluminum layer away from the color layer, the dry coating amount of the glue solution is 0.5~2.0g / m 2 , and dried to obtain the adhesive layer.

[0057] Optionally, the base layer is a polyethylene terephthalate resin (Poly(ethylene terephthalate), PET) film, and the thickness of the base layer is 12-36 μ...

Embodiment 1

[0071] Coating release agent on one side of PET film with a thickness of 12μm, the dry coating amount is 0.05g / m 2 , dried to obtain a release layer. Wherein, the release agent includes water-soluble modified silicone resin, and its solid content is 1%.

[0072] Coating alcohol-soluble color ink on the release layer, the dry coating amount is 1.7g / m 2 , dried to obtain a color layer. Among them, the binder of the alcohol-soluble color ink is polyvinyl butyral and rosin resin with a weight ratio of 5:1, and the toner, additives, and solvents of the alcohol-soluble color ink are selected from environmentally friendly materials and adjusted according to the needs.

[0073] A vacuum aluminum plating machine is used to carry out vacuum aluminum plating on the color layer to form an aluminum layer with a thickness of 10 nm.

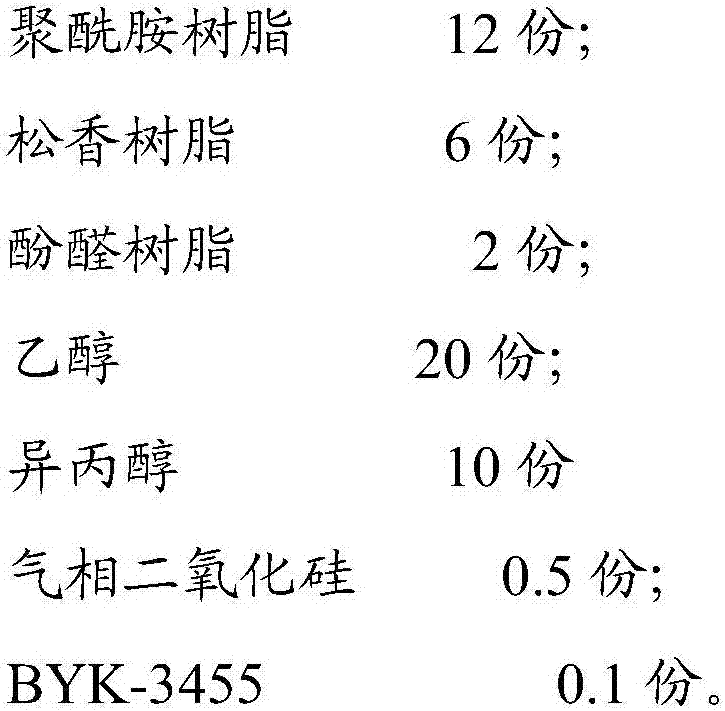

[0074] Coating glue on the aluminum layer, the dry coating amount is 1.0g / m 2 , dried to obtain a glue layer, and finally obtain the finished electrochemic...

Embodiment 2

[0079] Coating release agent on one side of PET film with a thickness of 20μm, the dry coating amount is 0.1g / m 2 , dried to obtain a release layer. Wherein, the release agent includes a water-soluble modified silicone resin, and its solid content is 5%.

[0080] Coating alcohol-soluble color ink on the release layer, the dry coating amount is 3g / m 2 , dried to obtain a color layer. Among them, the binder of the alcohol-soluble color ink is polyvinyl butyral and rosin resin with a weight ratio of 1:1, and the toner, additives, and solvents of the alcohol-soluble color ink are selected from environmentally friendly materials and adjusted according to the needs.

[0081] A vacuum aluminum plating machine is used to carry out vacuum aluminum plating on the color layer to form an aluminum layer with a thickness of 12nm.

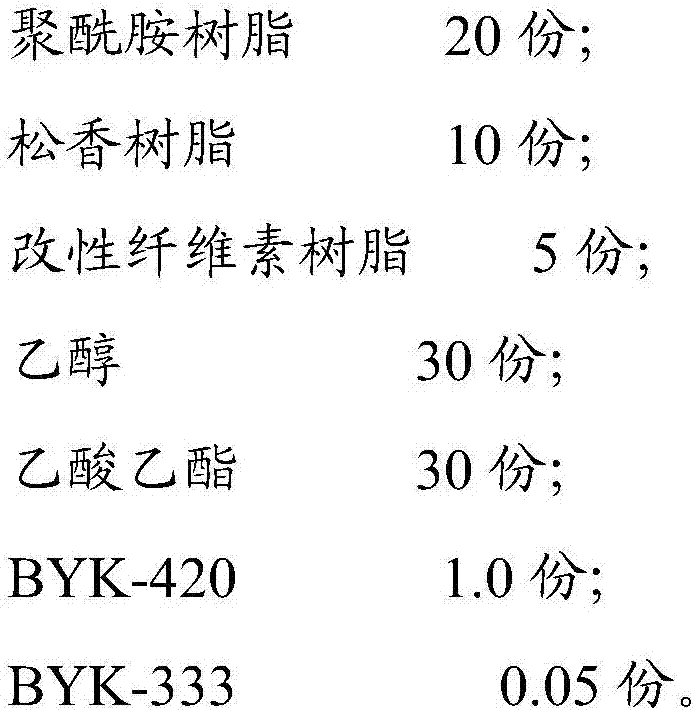

[0082] Coating glue on the aluminum layer, the dry coating amount is 2.0g / m 2 , dried to obtain a glue layer, and finally to obtain the finished electrochemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com