Composite material of nine cobalt octasulfide and titanium dioxide and its preparation method and application

A technology of titanium dioxide and composite materials, applied in the direction of electrolytic components, electrodes, energy input, etc., can solve the problems of unsuitable electrolytic water catalysts, etc., and achieve the effects of effective active reaction area, excellent hydrogen evolution performance and oxygen evolution performance, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

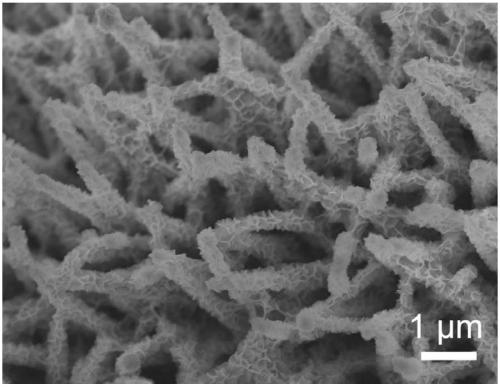

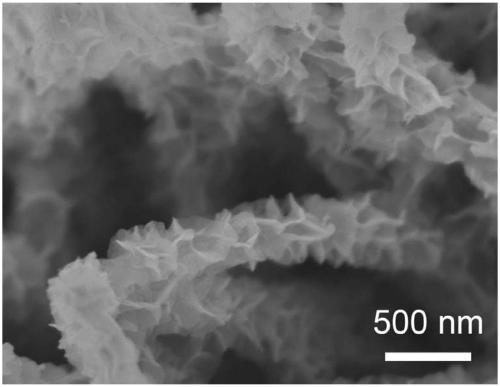

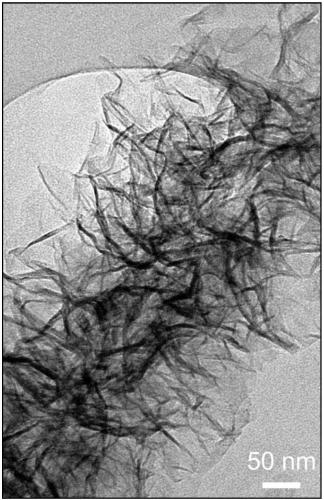

[0031] Weigh 0.6g of cobalt nitrate, 0.6g of urea and 0.15g of ammonium fluoride into a beaker, add 80ml of deionized water respectively, mix well, transfer the solution into a polytetrafluoroethylene autoclave, and put in foamed nickel As a substrate, the autoclave was sealed and hydrothermally reacted at 80° C. for 5 hours. After the reaction, cool to room temperature 25°C and wash with deionized water to obtain Co(OH) 2 CO 3 nanowire template.

[0032] Co(OH) 2 CO 3 The nanowire template was cleaned and placed in an atomic layer deposition instrument, with 0.01mol / L titanium tetrachloride and deionized water as the reaction source, the reaction temperature was 100 ° C, and the atomic layer deposition cycle was 80 weeks; the atomic layer deposition TiO 2 @Co(OH) 2 CO 3 nanowire template;

[0033] Weigh 50ml of 0.05mol / L sodium sulfide aqueous solution and place it in a blue cap bottle. Then put TiO 2 @Co(OH) 2 CO 3 The nanowire template was sealed and hydrotherma...

Embodiment 2

[0035] Weigh 0.9g of cobalt nitrate, 0.9g of urea and 0.225g of ammonium fluoride into a beaker, add 80ml of deionized water respectively, mix well, transfer the solution into a polytetrafluoroethylene autoclave, and put in foamed nickel As a substrate, the autoclave was sealed and hydrothermally reacted at 120° C. for 9 hours. After the reaction, cool to room temperature 25°C and wash with deionized water to obtain Co(OH) 2 CO 3 nanowire template.

[0036] Co(OH) 2 CO 3 The nanowire template was cleaned and placed in an atomic layer deposition instrument, using 0.05mol / L titanium tetrachloride and deionized water as the reaction source, the reaction temperature was 150°C, and the atomic layer deposition cycle was 120 weeks; the atomic layer deposition TiO 2 @Co(OH) 2 CO 3 nanowire template;

[0037] Weigh 50ml of 0.1mol / L sodium sulfide aqueous solution and place it in a blue cap bottle. Then put TiO 2 @Co(OH) 2 CO 3 The nanowire template was sealed and hydrotherm...

Embodiment 3

[0039] Weigh 1.2g of cobalt nitrate, 1.2g of urea and 0.375g of ammonium fluoride into a beaker, add 80ml of deionized water respectively, mix well, transfer the solution into a polytetrafluoroethylene autoclave, and put in foamed nickel As a substrate, the autoclave was sealed and hydrothermally reacted at 150° C. for 12 hours. After the reaction, cool to room temperature 25°C and wash with deionized water to obtain Co(OH) 2 CO 3 nanowire template.

[0040] Co(OH) 2 CO 3 The nanowire template was cleaned and placed in an atomic layer deposition instrument, using 0.15 mol / L titanium tetrachloride and deionized water as the reaction source, the reaction temperature was 200 °C, and the atomic layer deposition cycle was 160 weeks; the atomic layer deposition TiO 2 @Co(OH) 2 CO 3 nanowire template;

[0041] Weigh 50ml of 0.05mol / L sodium sulfide aqueous solution and place it in a blue cap bottle. Then put TiO 2 @Co(OH) 2 CO 3 The nanowire template was sealed and hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com